Screw Conveying

All helical screws, including conveyors, operate using the same principal action: loose bulk materials are transported via the rotation of an inclined face that provides a direct positive means of transfer. This is often an advantage over other conveying methods, such as belt or vibratory conveyors, where the solid’s movement is generally more passive.

When designing and operating a screw conveyor following a few essential design rules can prevent most problems and help efficiency. For optimal transfer, the cross-sectional load of a screw conveyor should not be above 45% fill. If the level of material exceeds the height of the screw’s shaft material can tumble over and back into the pitch space before. This in turn causes a cascade effect where material builds up towards the inlet and reduces the axial transfer efficiency. Overfill can be avoided by incorporating a reduced capacity feed control section at the inlet of the screw conveyor.

But before you start handling any material you need to know its character and how to work with it.

Working with the Material

Any solids handling project should begin with understanding the material’s characteristics and how these inform handling. Consequences of failing to do so range from transfer inefficiency to the material jamming the screw conveyor, causing resistance and even blockages, as well as potentially damaging the screw.

Irregular Materials

For most materials these issues can be avoiding by conducting a few standard tests and using the results to inform the design. However, materials such as waste are by their nature irregular and therefore inconsistent in the flow properties they exhibit.

A recent Ajax Equipment screw conveyor project involved handling shredded waste as part of a process to produce circular fuels and chemicals. After working with the customer to determine the needs of the material a trial conveyor was tested on site. The additional feedback helped to ensure the final design included the required inlet and outlet size, space between casing and screw, as well as flight design to accommodate the material’s varied proportions and ensure there was no trapping or jamming therein.

Cohesive Materials

Powders that are poor flowing and sticky can build-up over time on screw surfaces limiting the effectiveness for material transport. Damp salt is a strong example, capable of exposing any deficiencies in equipment and plant arrangement. As it is highly adhesive it tends to build-up on the casing and screw of a screw conveyor, restricting efficiency of transfer and in some cases causing blockages which damage the machine.

When Ineos Salt, the UK’s largest producer of vacuum salt products, wanted to improve transfer of salt from two driers to a tableting machine, Ajax Equipment was brought in to implement a new plant arrangement.

To help prevent the build-up of salt, and potential blockages, the second drier’s entry into the new shared collecting screw was offset. However, due to the limitations of the plant layout the new 3m conveyor needed to be inclined at 35°. Without proper consideration, conveying material at this angle would lead to some salt falling back. To ensure effective transfer Ajax combined specially selected flights with the appropriate rotational speed to generate the required radial pressure to drive the material forward into the collecting screw.

The collecting screw conveyor serves two outlets, each leading to processes with different material requirements. To prevent lumps of salt entering tablet production Ajax designed an outlet with tapered slots, ensuring unsuitable material continued to the second outlet as well as avoiding the need for a lump breaker.

Meeting Design & Process Challenges

Equally important as the needs of the material are those of the process. While some applications only need to transfer a short distance under normal conditions, when the distance is great or the temperature and pressure must be controlled conveying is not so simple.

Long Conveyors

Conveying over a large distance is a challenge. Usually screw conveyors are only required to cover a few metres or so. However, with longer screws, the length leads to a variety of design hurdles which must be overcome.

In one such project, Ajax Equipment was approached by a powder manufacturer which wanted to replace an inefficient, inclined belt conveyor, shown to be the primary factor in the plant’s low Overall Equipment Effectiveness score of 55%.

The long belt conveyor carried wet gel from two washers to a bucket elevator for further processing. Due to the steep incline of the belt conveyor the gel had a propensity to fall back and off the conveyor, with production losses of around 20kg from each washer discharge. This led to the bucket elevator not being filled efficiently and reduced production throughput.

To resolve the handling issues and allow the plant to run at its intended capacity, Ajax Equipment proposed replacing the belt conveyor with a 6m screw conveyor. After installing the screw conveyor and other changes, the plant’s Overall Equipment Effectiveness score increased to 76%. However, designing the conveyor wasn’t without its challenges.

The two biggest design issues were selecting flights for this hot, sticky and wet gel, and the length of the screw required. A screw with LynFlow ribbon flights in stainless steel was chosen as this would positively transfer the gel without overworking the material as well as prevent clogging. One solution to provide adequate support to the 6m screw would be to use hanger bearings. However, this would have impacted transfer effectiveness. Instead, the open design of the flights helped minimise the weight of the screw, while a robust centre tube meant intermediate support was not required.

Although it was possible to avoid hanger bearings in this case, the usual limit is in the region of 6-8m. Any longer and screws require support to prevent sagging. Ajax Equipment’s longest screw conveyor to date is 28m, an unusually long distance to cover with a single conveyor and so required a large amount of hanger bearings.

At such lengths, the resultant stresses are often a source of issues including excessive loading or bending stress; even fabrication and installation ‘trueness’ can impact whether the screw catches the conveyor’s casing. However, these can be mitigated with careful design and attention to detail in manufacture. To ensure good performance in the 28m long screw, Ajax ensured that each screw segment was very well aligned, preventing excessive loading, and that the hanger, bearing and flight design worked well together.

Controlling the Material’s Environment

Many materials vary with environmental conditions, however, for some processes these conditions must be managed.

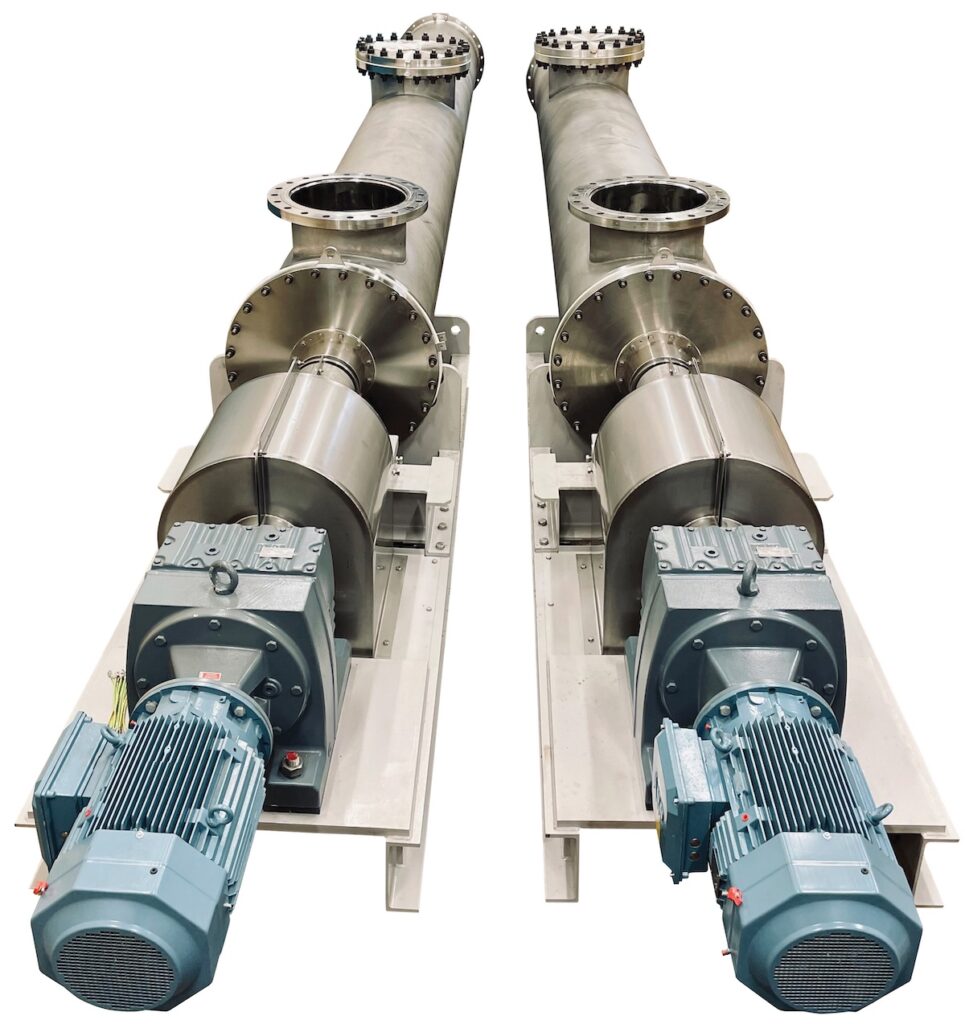

To alter the surface chemistry of biomass particles, PJH partnership required a conveyor that could transfer the particles while immersed in an organic solvent at temperature and under pressure. This meant the screw conveyor would need to comply with Pressure Equipment Directive (PED) and ATEX requirements. A further challenge was the conveyor needed to be inclined at 30°. To ensure a consistent temperature, Ajax selected an oil heated jacket that would envelope the conveyor’s casing to ensure an even distribution of heat.

The Keys to Effective Conveying

Although often a simple application, conveying should not be assumed be. As discussed above, many materials and processes require careful thought. Where these factors are not considered the material’s condition may be compromised, the transfer process inefficient or the conveyor susceptible to damage.

Investing in understanding the material and process even before the design stage pays off many times over the life of handling equipment provided the design is sympathetic to the material, process conditions and layout needs.