While this article focuses on screw conveyors, Sinfimasa also designs and manufactures custom-made bucket elevators and chain conveyors with the same engineering rigor. If you are interested, visit us at Powtech Nürnberg from September 23 to 25 at stand 12-430.

Understanding the product: The cornerstone of custom conveying systems

Each bulk solid presents specific challenges due to its physical and chemical properties. In the case of screw conveyors, where continuous movement and friction play a central role, selecting a standardized design without considering the product’s behavior can lead to blockages, wear, and inconsistent flow.

To prevent these issues, the process must begin with a technical characterization of the material. Parameters such as:

- Bulk density

- Particle size and shape

- Flowability and angle of repose

- Moisture content

- Abrasiveness

- Temperature

…are crucial to assess. These factors influence not only how the material flows but also how it interacts with mechanical components during transport.

Laboratory and pilot plant testing

To ensure reliability, testing must go beyond visual inspection. A combination of lab tests and full-scale pilot trials is recommended, including:

- Particle size analysis

- Flow and angle of repose testing

- Abrasiveness evaluation

- Moisture and cohesion measurements

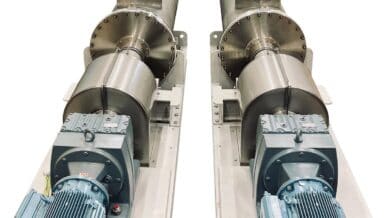

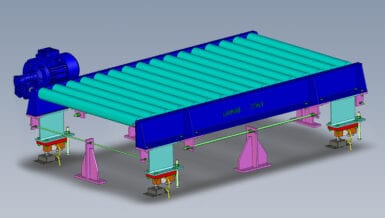

Design strategies for custom screw conveyors

Screw conveyors offer a compact, efficient solution for horizontal or slightly inclined transport of dry products, but only when properly adapted to the material characteristics.

Key design parameters:

- Helix type (shafted or shaftless)

- Screw diameter and speed

- Construction materials and protective coatings

For example, cohesive or wet products may require shaftless screws, which prevent material compaction around a central shaft. Additionally, elastomeric linings in the casing can reduce stickiness and provide protection against abrasion or corrosion.

Material selection:

- Carbon steels for general use

- Stainless or super-alloys for corrosive environments

- Wear-resistant steels or technical coatings for abrasive or high-temperature materials

All of these variables must be aligned with the plant’s capacity, ensuring smooth flow and minimal maintenance, even under demanding conditions.

Data-driven engineering for long-lasting performance

Investing in a custom screw conveyor, designed based on real data about the material, ensures:

- Consistent throughput

- Reduced unplanned stops

- Extended equipment life

- Lower energy consumption

- Compliance with industry standards

Conclusion: A customized approach, rooted in the precise analysis of the bulk solid, is the foundation of reliable and efficient screw conveyor design. At Sinfimasa, we begin each project with detailed lab and pilot testing, transforming product behavior into optimized engineering.