FEECO’s pin and pugmill mixers are used throughout various industries to accomplish diverse goals, from simple mixing to preconditioning feedstock, and even agglomeration. In industries where precise material handling and particle control are essential, mixers can provide critical value beyond basic blending.

About Pin & Pugmill Mixers

Pin and pugmill mixers have long been used throughout the industrial sector to achieve mixing objectives, with industries such as carbon black preferring the pin mixer, and more robust applications relying on the pugmill mixer.

Both mixer types blend solid and liquid feed components into a homogeneous mixture, but each does so in very different ways. Exploring the key differences between them leads to a greater understanding of the extent of their capabilities.

Pin Mixers

Pin Mixer Construction

A pin mixer consists of a single shaft fitted with rods or “pins” that spins at a high RPM inside of an enclosed cylindrical housing.

Pin Mixer Operation

The high-speed rotation of pins within the cylindrical housing of the pin mixer creates centrifugal force that not only mixes the components together but also causes material to densify as it moves through the mixer.

A spray system distributes the liquid component into the rotating bed of material at predetermined locations.

Pugmill Mixers

Pugmill Mixer Construction

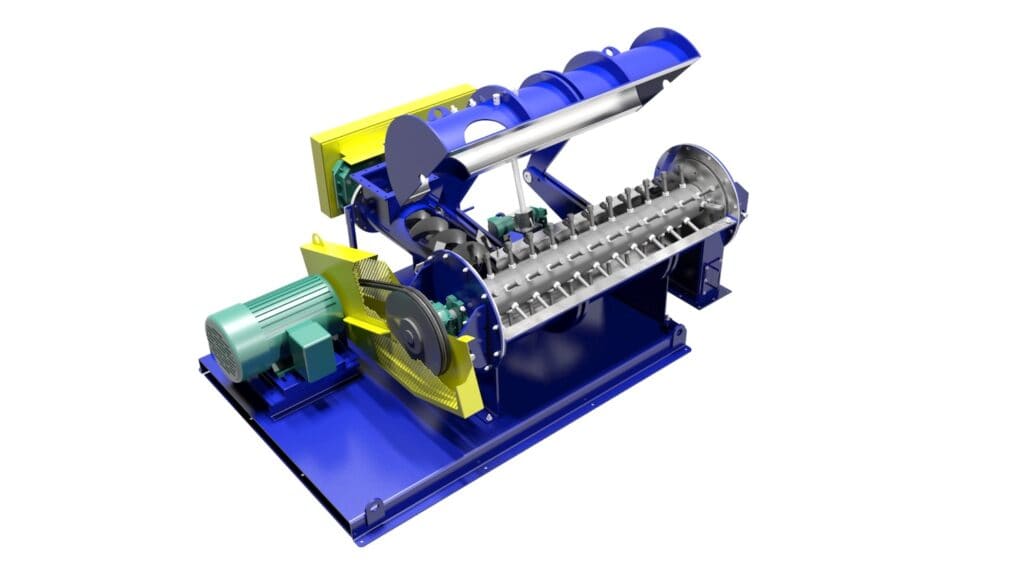

A pugmill mixer, often referred to as a pug mill or paddle mixer, utilizes two counter-rotating shafts fitted with pitched paddles inside an enclosed u-shaped trough.

Pugmill Mixer Operation

While the pin mixer uses a fast-spinning action, the action inside of a pugmill mixer is slower and more forceful – a high-torque kneading or folding action resulting from the counter rotating shafts.

Again, a spray system distributes the liquid component over the tumbling material bed at predetermined locations.

Mixing

Both mixer types offer an effective solution to continuous process mixing.

The high rotational speed associated with the pin mixer lends well to mixing fine powders such as pigments and dyestuffs, carbon black, coal, and ceramics.

In contrast, the slow, high torque mixing action of the pugmill mixer is better suited to applications requiring a more rugged mixing device, such as when mixing copper concentrates, flux, and reverts prior to a smelter, or when blending steel mill byproducts for recovery in the steelmaking process.

Similarly, pugmill mixers are often employed in mixing waste materials in the form of water-laden sludges and fines, blending them into a more manageable form for disposal. The slower, high-torque action of the pugmill mixer is also better suited to working with abrasive materials.

Preconditioning

The ability to create a homogeneous mixture from solid and liquid feed components is invaluable, aiding in the production of a range of industrial products.

It also, however, makes these mixers ideal as a pretreatment step in a larger agglomeration process, particularly given that, by modifying binder addition and potentially pin/paddle arrangement, both can produce “seed pellets,” or small starting granules for growth layering.

With both mixers, dry feed and binding agent can be seamlessly blended to produce a uniform mixture for further processing in the primary agglomeration equipment. Because mixing in the primary agglomeration device is otherwise minimal, a pre-mixing step translates to a more uniform end product.

In general, pin mixers are typically paired with disc pelletizers, as they can produce uniform “seed pellets” ideal for additional layering on the disc pelletizer. The pin mixer-disc pelletizer pairing yields a high rate of on-size, highly uniform spherical granules.

This approach to pelletizing can be found throughout a range of industries but is especially common with soil amendments where uniform particle size distribution is a top priority. This setup is frequently used to process both gypsum and limestone soil amendment products.

Pugmill mixers, which produce a mix of rough agglomerates ranging in size, are generally paired with granulation drums. Solid and liquid feed are blended in the pugmill mixer and the resulting rough agglomerates are tumbled in the granulator for further refinement.

This approach is often seen with manure-based fertilizers, where the mixer’s high torque is particularly advantageous.

Agglomeration

The ability to produce seed pellets or rough agglomerates also means these mixers can serve as standalone agglomerators as well.

The pin mixer can yield small, dense agglomerates with a narrow particle size distribution. These “micro pellets” are ideal for use in chemical processes such as pigment production, as well as in other settings that benefit from smaller granules, such as soil amendments in turf applications.

Perhaps less common, the agglomerates produced by the pugmill mixer, though rough, can be sufficient in settings where particle size distribution and sphericity are less of a concern.

Depending on the mixer in use, granule density can be enhanced by either increasing the material’s retention time (pugmill mixer) or speeding up the shaft (pin mixer).

Conclusion

FEECO pin and pugmill mixers are far more than simple mixing devices, serving as versatile, high-performance tools capable of executing critical process functions beyond just mixing. With the ability to produce everything from homogeneous mixes to dense seed pellets or rough agglomerates, these continuous mixers offer significant value across a wide range of industries and applications. Whether enhancing downstream granulation or serving as a primary agglomeration device, FEECO mixers are engineered to deliver process efficiency, product consistency, and long-term durability.