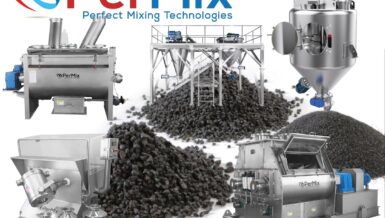

Suitable for mixing food, nutrition, chemical, and pharmaceutical products, the Gericke continuous mixers automatically meter multiple dry and liquid materials into a mixing chamber where both axial and radial dispersion are applied in a fluidized zone with forward motion. The novel design achieves throughputs of up to 150,000 liters/hour and/or 100 tons/hour of dry materials for peak efficiency in high capacity mixing.

The Gericke continuous mixers are available in optional FDA-compliant configurations for sanitary processes and ATEX-certified configurations as explosion-proof for hazardous environments, and in custom designs to meet virtually any requirements. The mixers may be tested at the Gericke test laboratory.