Gericke Feeding, Mixing, Conveying, Size Control Technology. High-class workmanship for a world of industry. Gericke supplies conveying, sifting, high-precision feeding, and mixing solutions that handle a broad range of ingredients such as pellets, powders, floodable powders and fibreglass for food, chemical, industrial, and pharmaceutical industries.

Gericke process steps include:

- Reception of the raw materials

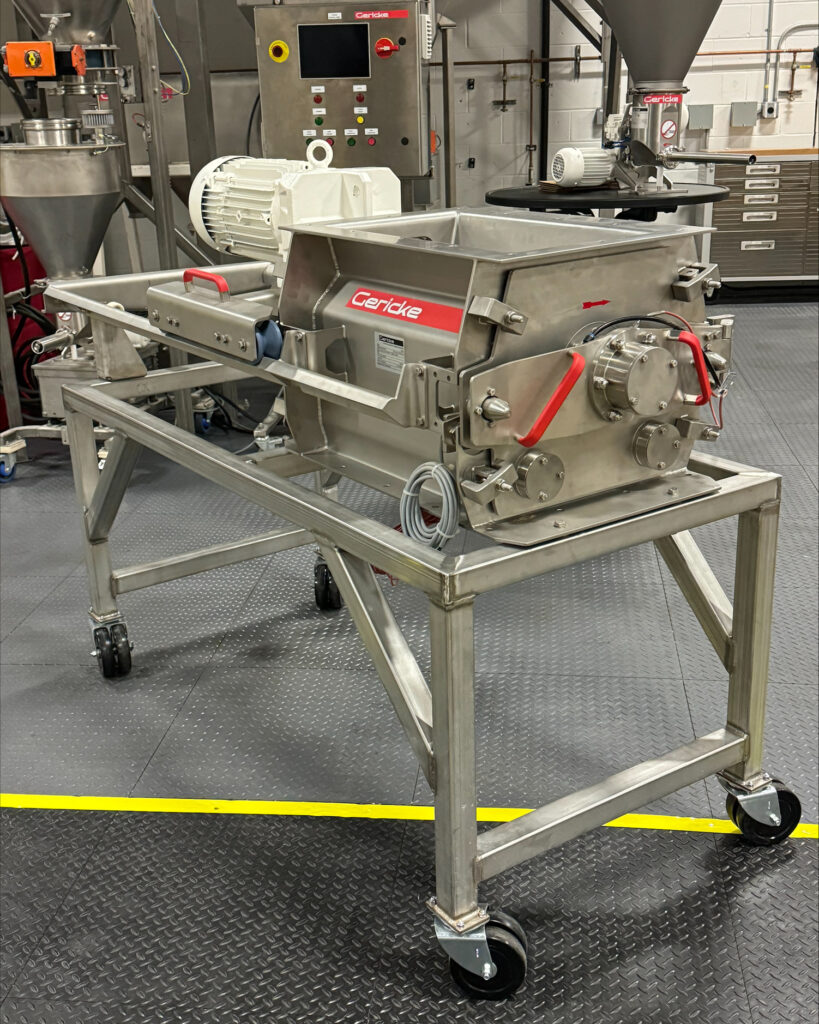

- Control sifting, breaking down of agglomerates

- Pneumatic Conveying

- Feeding

- Mixing processes

- Filling

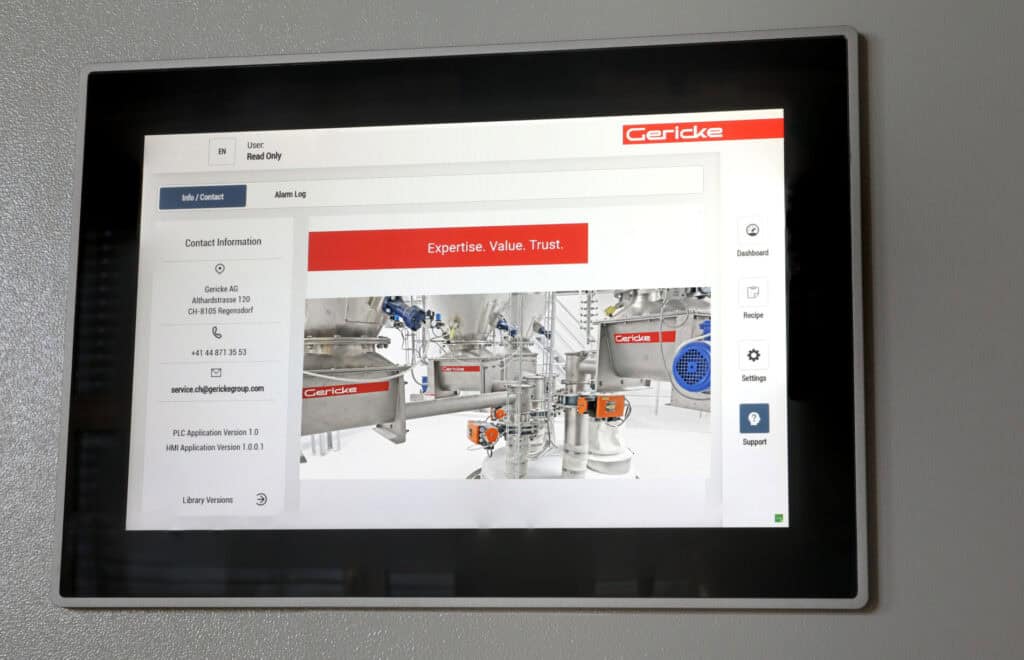

- Automation

Gericke Holding

Gericke has been supplying total packages for conveying, feeding and mixing projects for the processing of bulk materials since 1894. The optimal combination of innovation, operational safety and service means additional value and success for our customers! The development of our technology and products occurs in close co-operation with our customers. Our Gericke Test Centres provide facilities for customers to carry out realistic tests.

United States

Gericke USA, Inc 14 Worlds Fair Drive, Suite C 08873-1364 Somerset-NJ USA T +1 855 888 0088 (local) sales.us@gerickegroup.com