It is overly optimistic to assume that all powders used in the food industry are free-flowing. In fact, most are cohesive, and assessing their level of cohesiveness is crucial for predicting flow behavior. If a powder or powder blend is cohesive, it may present challenges due to poor flow behavior and a tendency to compact.

What is cohesion?

At the particulate level, two main interaction mechanisms occur: adhesion and friction. Adhesion results from particle-to-particle or particle-to-surface contact forces. If these forces occur, the particles will be attracted to each other and adhere. Adhesion is therefore a prerequisite for cohesion.

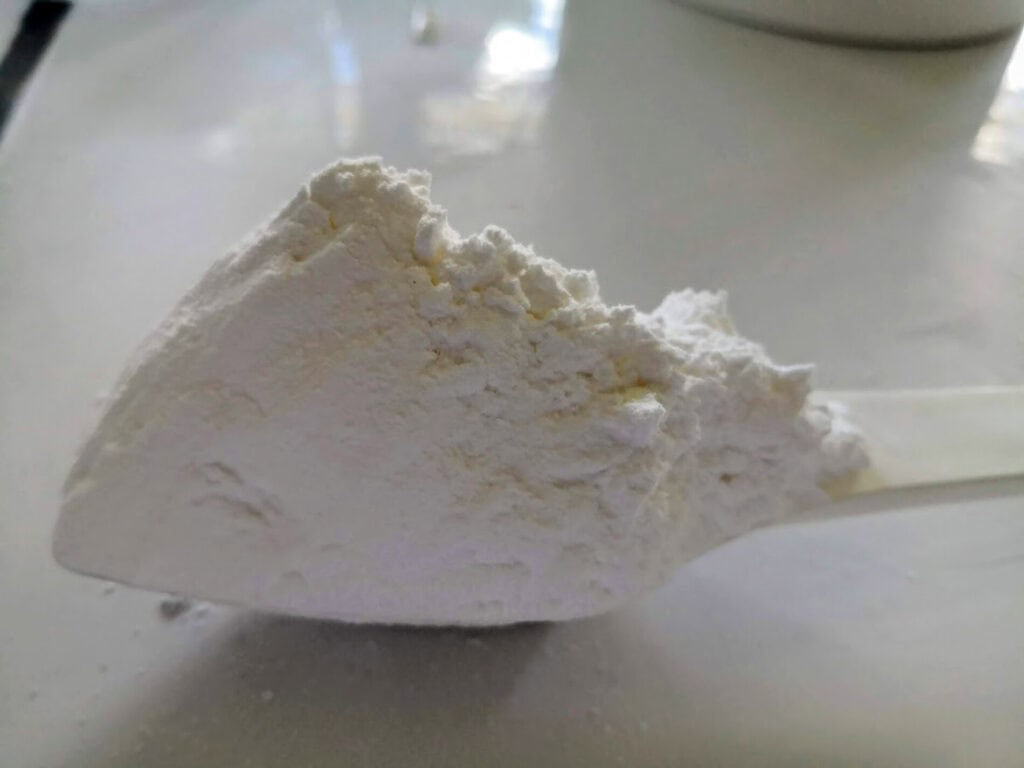

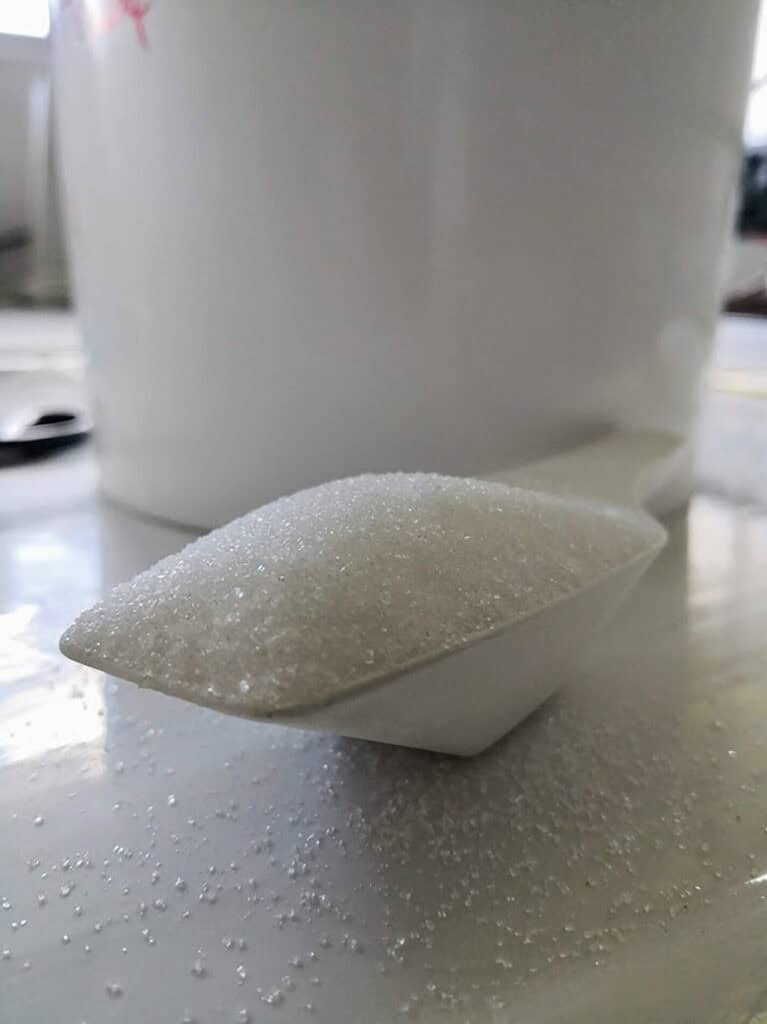

To measure cohesion, there is a simple test widely used in industry. You simply pour a certain amount of powder through a funnel onto a flat surface and measure the angle of repose. If the angle is less than 30°, the powder is classified as free-flowing. If higher, then it is cohesive. Figure 1 shows a cohesive powder (fine lactose) on the left and a free-flowing powder (crystal sugar) on the right.

Figure 1 – Difference in the angle of repose between a cohesive powder – fine lactose – (left) and a free-flowing powder – crystal sugar – (right).

The particle size of the powder is a critical factor determining cohesion. Free-flowing powders exhibit a high flowability and generally have a mean diameter greater than 100 micrometers. Particles of this size do not tend to agglomerate by cohesion.

On the other hand, in the case of cohesive powders, the flowability of the powder decreases. This is due to the predominance of cohesive forces. Cohesive powders are mainly composed of fine particles with a mean diameter less than 100 micrometers.

Therefore, flowability is significantly different between powders belonging to these two groups.

Mixing free-flowing with cohesive powders

The behavior of bulk powder is highly influenced by the way particles are arranged. If a powder or a powder mixture is composed of particles of different sizes and shapes (spherical, angular, irregular, etc.), predicting the structure of a powder bed is quite challenging. For example, what happens when you mix a free-flowing powder with a cohesive powder? This question has been explored by many researchers, among them Léonard Legoix and team [1], who investigated the influence of the powder structure on flow behavior in a mixer. Free-flowing semolina was mixed with cohesive lactose. The study showed that when lactose is combined with semolina, the fine lactose particles tend to coat the larger semolina particles and fill the voids between them. This coating effect becomes more pronounced as the particle size of the lactose decreases. They also showed the importance of looking at the whole powder system and investigating the final consolidated state of the powder bed after mixing, especially when cohesive powders are part of the blend.

It is well known that free-flowing powders are not very sensitive to compaction, unlike cohesive powders, which tend to compact more easily. Legoix et al. showed that the way powders mix depends on the small-scale structure of the blend. Their study found that the mixture behaves like a free-flowing powder when semolina forms the main structure and the spaces in between are simply filled with lactose particles. But when the semolina particles are coated with lactose, the mixture starts to behave more like a cohesive powder, because the contacts between particles are mainly between the fine lactose rather than the semolina.

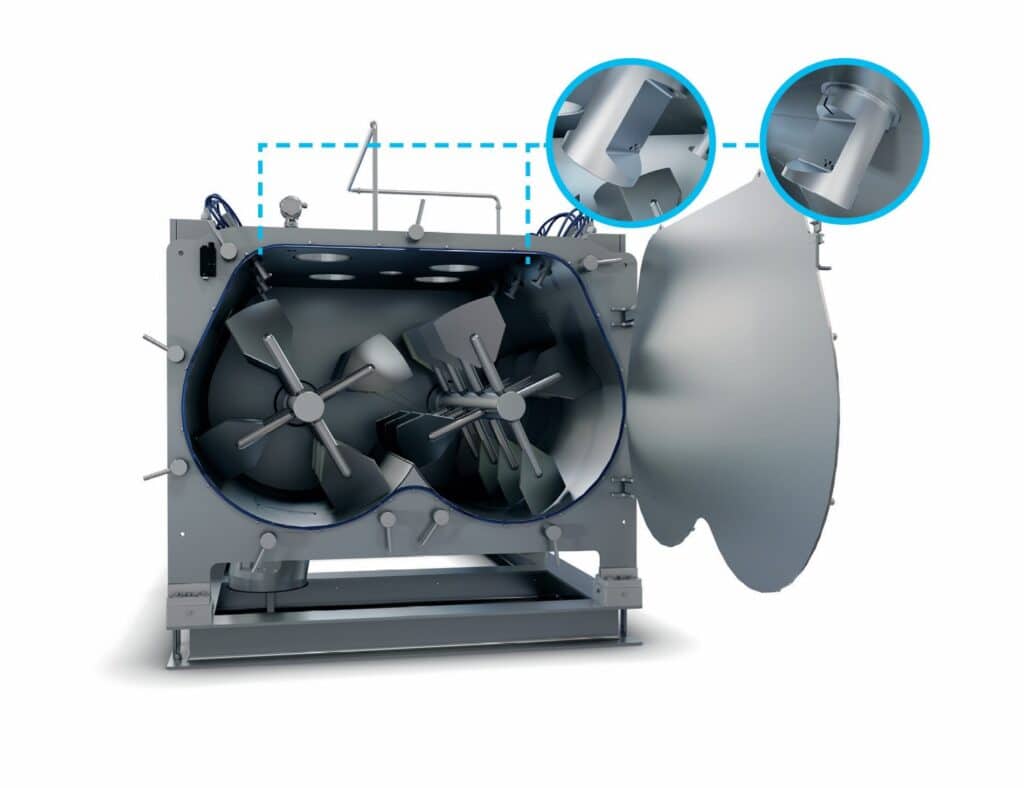

A similar result was observed during an experiment at our Powder Development Centre in France, which includes both a research lab and a pilot plant for Powder Process & Technology. We ran tests in our double-shaft paddle mixer, partially filled with 700 kg of crystal sugar, and measured the load on the paddles. When we added 300 kg of milk powder, the load on the paddles dropped by half—even though we had added more material. This happened because the milk powder partially coated the sugar particles, reducing friction against the paddles. It’s a good reminder that to understand how much load your process will generate, you need to look closely at the microscopic characteristics of the entire recipe.

Cohesion and cleaning

Cohesion also has an influence on how easy it is to clean a batch mixer. Let us illustrate this point by taking a closer look at our Air Jet technology for the cleaning of mixers such as double shaft paddle mixers. This technology is available as an upgrade or an option not only on our mixers but also on other brands of powder mixers.

Jets of air from nozzles are used to dislodge powder from the mixing chamber as an automatic method of dry cleaning without opening the mixer and with no water needed. It works for most powders used in the food industry with some exceptions. To tell, with a high degree of accuracy, which powders will work with our technology and which will not, a lab test in our FT4 Rheometer that takes just one hour is performed.

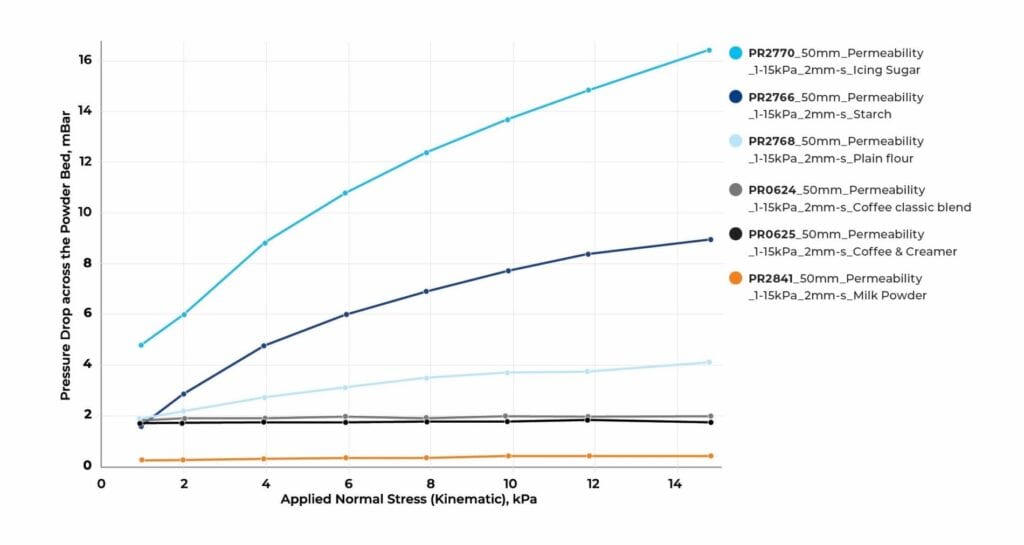

The graph (see Figure 4) shows the results from our permeability test with a variety of used powders. The vertical scale in millibars on the graph is calculated by measuring the permeability of the sample and indicates the capability of air to pass through the powder bed in the FT4 rheometer. The higher the pressure drop, the more resistant the powder is to air jets. When values are below 5 millibars, we consider that our Air Jet technology will efficiently remove powder. Hence this test provides a fast measurement of cohesion to give a good indicator if a customer’s powder is feasible for the new technology. All that’s needed is a 30 g sample for testing purposes.

The results demonstrate that starch particles with a mean diameter of 15 µm and icing sugar with a mean diameter of 17 µm are too cohesive effectively dislodged by the Air Jet Technology. In contrast, milk powder with a mean particle size of 130 µm is expected to be compatible with the new cleaning method. This expectation was confirmed through full-scale tests in the paddle mixer, where the amount of residual powder left in the tank was reduced dramatically from 50 liters to just 50 milliliters.

How a paddle mixer works

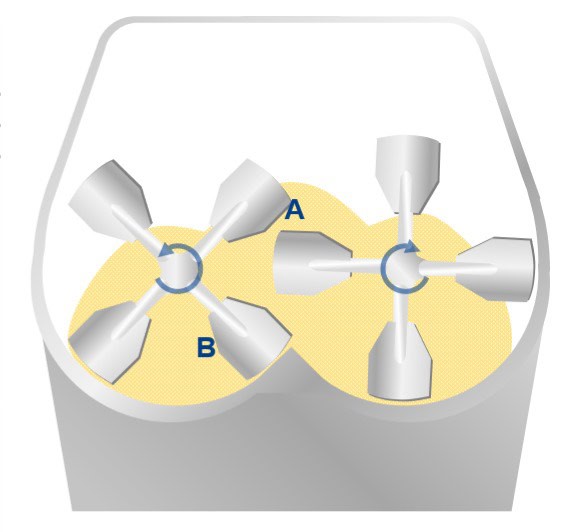

The double shaft paddle mixer is a sophisticated version of the simple paddle mixer. What’s special about this mixer is the configuration with two horizontal shafts, each equipped with seven ranges of blades rotating in opposite directions in a closed tank (see Figure 5). A recirculation flow is developed inside the vessel to sweep a maximum amount of material from one side to the other thanks to deflection paddles. This ensures the crossover of the two flows inside the mixing chamber creating a fluidized zone (zone A in Figure 5).

Modelling the behavior of a powder in a paddle mixer

Dr. Hayfa Boussoffara, our Powder Technology Specialist at Tetra Pak Powder Process & Technology, brings together a solid academic background and hands-on experience in powder handling. She recently completed her Ph.D on the rheology of powders in paddle mixers—the scientific study of how powders flow under mechanical forces.

Her research established links between the rheological and physical properties of powders during mixing operations [2]. By examining how powder rheology influences the forces exerted during the established mixing regime, her work provides a process-oriented perspective that supports the prediction of powder behaviour. She proposed an experimental model that offers a promising alternative for anticipating both powder behaviour and the mechanical load on the paddles during mixing. This approach contributes to improved process efficiency and reliability, while also supporting the robust performance of industrial mixers across a wide range of powders and operating conditions.

Bibliography

[1] L. Legoix, C. Gatumel, M. Milhé, and H. Berthiaux, ‘Characterizing powders in order to determine their flow behavior in a mixer: From small scale observations to macroscopic in-mixer rheology for powders of various flowabilities’, Powder Technology, vol. 322, pp. 314–331, 2017b, doi: 10.1016/j.powtec.2017.07.075.

[2] H. Boussoffara, C. Gatumel, B. Malécot, M. Viau, and H. Berthiaux, ‘A rheological law to describe powder agitation in a lab-scale paddle mixer: Shear band observation and dimensional analysis’, Powder Technology, vol. 451, p. 120469, Feb. 2025, doi: 10.1016/j.powtec.2024.120469.