Despite its mundane presence, dust is a complex blend of organic and inorganic materials, varying considerably based on the environment. From pollen in the air to fine desert sands, dust links us to broader ecological and geological contexts. Understanding dust in its various forms is crucial for appreciating the more intricate and less visible varieties, such as nano-dust, which has profound implications for health, technology, and the global environment.

Characteristics and Significance of Nano-Dust

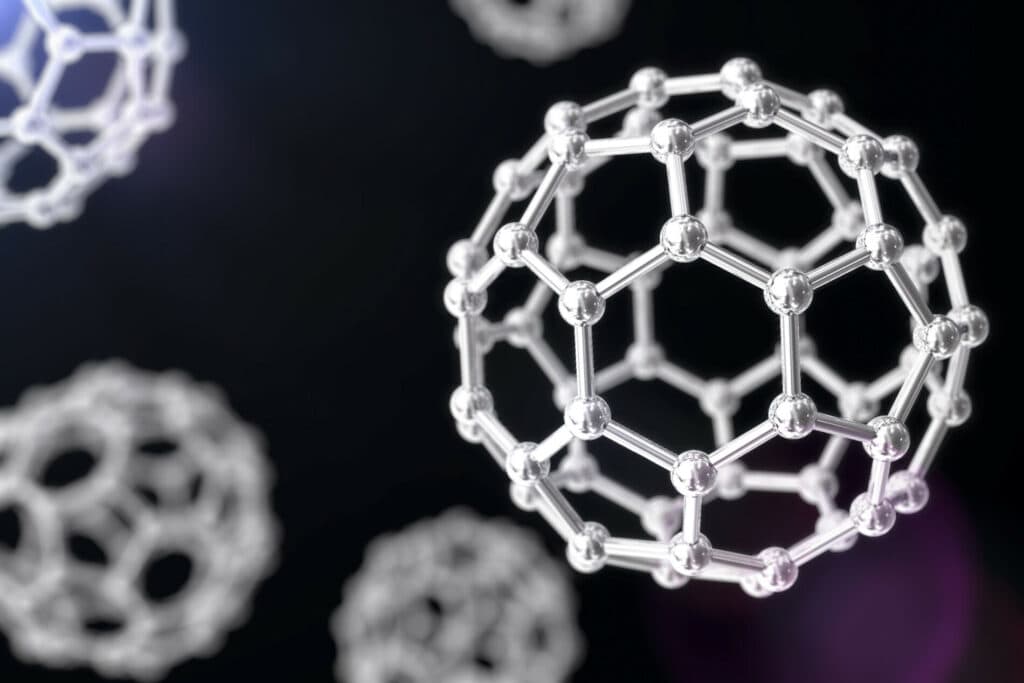

Nano-dust particles, owing to their infinitesimal size, possess an exceptionally high surface-to-volume ratio. This characteristic endows nano-dust with enhanced chemical reactivity and unique electronic and optical properties due to quantum confinement effects. These properties are pivotal in various industrial applications, from catalysis to electronics and environmental monitoring.

The increased surface area relative to volume allows nano-dust to interact more extensively with surrounding materials, significantly impacting reactivity and interaction processes. When particle sizes approach the nanoscale, quantum mechanical effects become prominent, altering electronic and optical behaviors. This is particularly relevant in developing advanced materials and devices.

Formation and Sources of Nano-Dust

Nano-dust can form through several processes, including chemical vapor deposition, agglomeration, and surface peeling. In plasma environments, such as those in fusion reactors, the polymerization of reactive plasma species can generate nanometer-sized solid dust particles. This process is a key mechanism for nano-dust creation.

Naturally occurring nano-dust can arise from various environmental and geological processes. Volcanic eruptions produce nano-sized particles of silica and other minerals through the rapid cooling and condensation of volcanic ash and gases. Forest fires generate nano-sized soot and ash particles from organic matter combustion. The gradual breakdown of rocks and minerals through weathering and erosion releases nano-scale particles into the environment.

Human activities also contribute to nano-dust formation through industrial and technological processes. Combustion processes, such as burning fossil fuels and biomass, generate nano-sized particulate matter. Industrial manufacturing processes, including welding, metal melting, and chemical synthesis, often produce nano-dust as byproducts. Additionally, the intentional production of nanomaterials for applications in electronics, energy, and medicine significantly contributes to the presence of engineered nanoparticles in the environment.

Detailed Characterization of Nano-Dust

Characterizing nano-dust is complex due to its small size. Advanced analytical techniques are employed to study the properties and behaviors of these particles. X-ray Nano Computed Tomography provides three-dimensional visualization and analysis of nano-dust particles, revealing their size, shape, and internal structure. Dynamic Light Scattering (DLS) is used to determine the hydrodynamic diameter of particles in suspension, offering insights into their agglomeration behavior. Atomic Force Microscopy (AFM) allows for high-resolution imaging of the surface topography and morphology of individual nano-dust particles. Techniques such as time-of-flight mass spectrometry analyze the chemical composition and size distribution of nano-dust samples.

Drum testing can simulate real-world conditions to study nano-dust behavior under various environmental and mechanical stresses. These tests help assess how nano-dust particles interact with surfaces, their potential for resuspension, and their impact on air quality.

Air testing methods measure nano-dust in the air, providing valuable data on airborne particle concentrations and distributions. Gravimetric analysis involves drawing air through filters to capture dust particles and weighing them to determine overall concentration. Optical Particle Counters (OPCs) use light scattering to count and size particles in real time, offering a quick assessment of dust levels. Aerosol Mass Spectrometry provides detailed chemical composition analysis of airborne dust particles. Each method has its advantages: gravimetric analysis is highly accurate for total dust mass concentration but lacks real-time capabilities, whereas OPCs and aerosol mass spectrometry offer real-time data and detailed particle characterization but can be more complex and expensive to operate.

Industrial Applications and Challenges of Nano-Dust

The presence of nano-dust in industrial environments poses both challenges and opportunities. Engineers in powder handling installations must navigate these complexities to optimize processes and ensure safety. Nano-dust can significantly impact air quality within industrial facilities. Advanced filtration systems are crucial for capturing these particles and preventing them from affecting worker health and environmental conditions. Utilizing high-efficiency particulate air (HEPA) filters and other advanced filtration technologies can effectively capture nano-dust particles. Continuous monitoring using optical particle counters and aerosol mass spectrometry ensures real-time data on airborne nano-dust concentrations, facilitating prompt responses to elevated levels.

Nano-dust’s unique properties can be harnessed to improve various industrial processes. The high surface area of nano-dust particles makes them effective catalysts in chemical reactions, enhancing the efficiency of processes such as fuel production and chemical synthesis. Nano-dust can also be used to develop advanced materials with improved properties, such as increased strength, durability, and thermal resistance.

Health and Environmental Risks of Nano-Dust

The potential health and environmental impacts of nano-dust cannot be overlooked. Ensuring safe handling and disposal practices is essential to mitigate these risks. Inhalation of nano-dust particles can lead to respiratory issues and other health concerns, making proper ventilation and protective equipment vital. Additionally, nano-dust can affect ecosystems if released into the environment, necessitating effective containment and waste management strategies to prevent contamination.

With increasingly stringent legislation and the potential dangers associated with nanoparticles, understanding nanoparticle analysis and nanoparticle size analysis has become crucial. The European Commission has identified various techniques and methodologies to analyze nanoparticles in diverse materials and determine their classification as nanomaterials. Unlike conventional bulk materials, nanoparticles require dedicated techniques, methodologies, and pre-treatment procedures for accurate qualification and quantification.

Advanced Techniques for Nanoparticle Analysis

It is essential to distinguish between nanoparticles that are intrinsically present in a product and those that become airborne due to product handling under certain conditions. The analysis often focuses on nanoparticles inherently present in products. However, airborne nanoparticles, especially in dust form, are typically investigated using methodologies like the small rotating drum technique in accordance with the EN-17199-4 standard. This standard, issued in 2019, addresses the release of nanoparticles into the air, which can cause inhalation exposure if these particles become airborne.

Despite the presence of nanoparticles in certain products and their classification as nanomaterials, it remains crucial to understand the conditions under which exposure might occur. Effective analysis and monitoring are vital to assess the risk of nanoparticles becoming airborne, ensuring that industrial practices adhere to safety standards.

Future Research Directions in Nano-Dust

The study of nano-dust is evolving, with ongoing research uncovering new insights and applications. Future advancements in computational modeling and simulation will further enhance our understanding of nano-dust behaviors and interactions. Techniques such as molecular dynamics and density functional theory will allow for predictive modeling of nano-dust behavior under various conditions, aiding in the design of safer and more efficient industrial processes. As research progresses, new applications for nano-dust in fields such as quantum computing, energy storage, and biomedical engineering are likely to emerge.

Conclusion

For industrial engineers handling and processing dry bulk materials and ingredients, comprehensively understanding nano-dust is critical for optimizing industrial processes, ensuring worker safety, and mitigating environmental impacts.

Continued research and technological advancements will further illuminate the complexities of nano-dust, paving the way for innovative applications and improved industrial practices.

This consistent and comprehensive article integrates detailed information on nano-dust, its characterization, industrial applications, and health and environmental considerations, tailored for professionals in powder processing and other relevant industries.