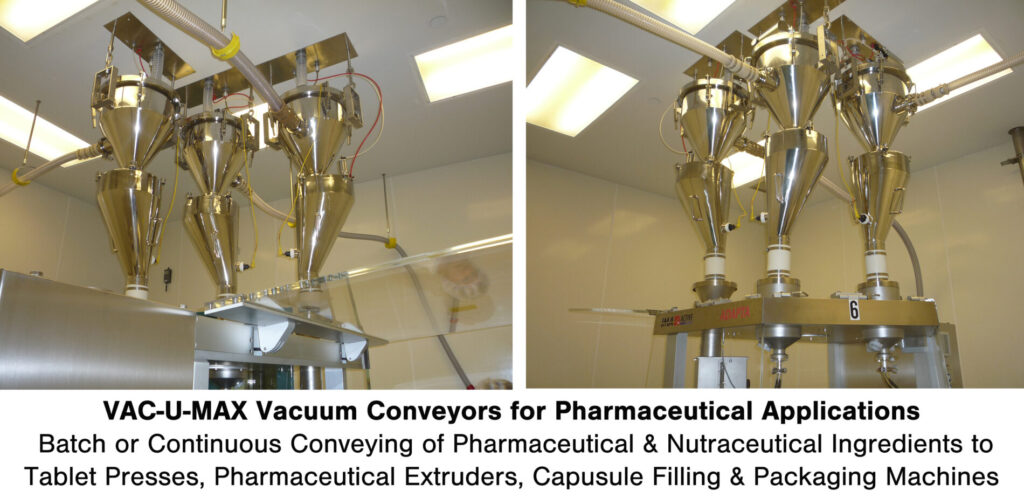

Vacuum Conveying a Broad Range of Pharmaceutical Powders

VAC-U-MAX pneumatic conveying systems are expertly designed to handle the diverse array of powders and bulk materials found in pharmaceutical and nutraceutical production, including:

- Magnesium stearate (Mag Stearate)

- Microcrystalline cellulose

- Lactose

- Mannitol

- Talc

- Gelatin

- Active pharmaceutical ingredients (APIs)

- Granules and excipients

- Nutraceuticals

- Tablets and capsules

- and more!

These materials, each with their own unique flow characteristics, bulk densities, and dusting potential, require specialized handling solutions. VAC-U-MAX systems are designed to maintain particle integrity, avoid segregation, and minimize exposure during transfer.

Beyond Pharmaceutical Feeders: Complete Process Integration

Pneumatic conveying systems from VAC-U-MAX are not limited to refilling pharmaceutical feeders. VAC-U-MAX vacuum conveyors integrate into every step of the production process, supporting:

- Capsule filling machines: High accuracy, contained powder transfer directly from drums or bulk bags to capsule fillers ensures continuous operation with minimal operator involvement

- Tablet presses: Powders like magnesium stearate are metered precisely into tablet press forms by refilling micro ingredient feeders, which require low-volume, high-accuracy conveying solutions that preserve powder properties

- Packaging lines: Finished products, including tablets and capsules, are pneumatically conveyed to packaging equipment, reducing manual handling, messy dumping, while ensuring consistent throughput

- Pharmaceutical Extruders: Vacuum conveyors refill dosing devices, delivering excipients and API’s in batch or continuous process

Sanitary Design: No Edge, No Ledge

For pharmaceutical applications, sanitary design is non-negotiable. VAC-U-MAX meets and exceeds industry expectations with a “no edge, no ledge” design philosophy, ensuring all contact surfaces are free from crevices where product can accumulate and microbial growth can occur.

Key design features include:

- 316L stainless steel construction: Provides superior corrosion resistance and cleanability

- Electropolished surfaces: Deliver a smooth finish that resists powder adhesion.

- Full passivation: All contact surfaces are passivated to meet sanitary standards and reduce contamination risk

- Tri-Clamp fittings and sanitary gaskets: Enable easy disassembly for inspection, cleaning, and validation

Safe Powder Conveying with HEPA Filtration

In pharmaceutical processing, safety is paramount, not just for the product, but for the operators and the processing environment. VAC-U-MAX vacuum conveying systems include integrated HEPA filtration for capturing fine and hazardous particles, ensuring a clean working atmosphere and compliance with dust containment regulations.

- HEPA and ULPA filters: Achieve 99.99% efficiency for sub-micron particles

- Pulse-back filter cleaning systems: Maintain optimal airflow and filter performance with automated, tool-free maintenance

- Contained loading and unloading: Minimizes operator exposure to potent compounds and allergenic materials

VAC-U-MAX Vacuum Receivers: Designed for Cleanability and Compliance

VAC-U-MAX vacuum conveyors are engineered to support fast cleaning protocols, crucial for reducing downtime between batches and preventing cross-contamination:

- Tool-less disassembly: Enables quick access to all components for cleaning and maintenance

- Modular design: Allows for easy configuration changes and system expansion

- Validation-ready documentation: All systems are supported with documentation packages for IQ/OQ validation, critical for

FDA compliance

A Complete Solution for Pharmaceutical Manufacturing. Whether conveying magnesium stearate to micro feeders, delivering powders to capsule filling machines, or transferring nutraceuticals to packaging lines, VAC-U-MAX offers a comprehensive, validated, and operator-friendly solution. With a proven track record in delivering high-containment, sanitary, and efficient powder transfer systems, VAC-U-MAX is a trusted partner in the pharmaceutical and nutraceutical industries.