Advanced Materials for Silos and Containers

The choice of materials for constructing silos and containers profoundly affects their durability and performance. While traditional steel structures have served us well, they are not without their vulnerabilities. Enter innovations in advanced materials:

- Fiber-Reinforced Polymers (FRP): These materials offer exceptional corrosion resistance, ideal for storing corrosive bulk materials like fertilizers and chemicals. Lightweight, durable, and requiring minimal maintenance, FRP structures cut long-term operational costs.

- Concrete Alternatives: Engineers are exploring innovative concrete alternatives, such as ultra-high-performance concrete (UHPC) and geopolymer concrete, for building silos and storage structures. These materials provide enhanced strength, durability, and resistance to chemical degradation.

IoT-Enabled Monitoring and Predictive Maintenance

The integration of the Internet of Things (IoT) into dry bulk storage technology has ushered in a new era of monitoring and maintenance practices:

- Sensor Networks: Sensors scattered throughout storage structures continuously collect data on temperature, humidity, material levels, and structural integrity. This real-time information allows for the early detection of issues and proactive maintenance.

- Predictive Analytics: Advanced analytics and machine learning algorithms dissect sensor data to forecast maintenance requirements and potential material flow problems. Predictive maintenance slashes downtime and reduces repair costs.

- Remote Monitoring: IoT-enabled systems enable operators to monitor storage facilities remotely, granting access to critical data and the ability to respond swiftly to changing conditions or emergencies.

Sustainable Storage Solutions

Sustainability is at the forefront of material handling concerns. Innovations in dry bulk storage technology are addressing environmental impact and resource efficiency:

- Solar-Powered Aeration Systems: Essential for preventing material bridging and clogging, silo aeration systems can now harness solar energy. This eco-friendly approach diminishes dependence on conventional power sources and trims operational costs.

- Modular and Stackable Designs: Modular silo designs offer scalability and flexibility. Stackable containers minimize the storage facility’s footprint, efficiently utilizing available space and reducing land requirements.

- Recycled and Eco-Friendly Materials: Some storage solutions now incorporate recycled and sustainable materials in their construction, decreasing the environmental footprint of storage facilities.

Enhanced Material Flow Control

Efficient material flow is the lifeblood of production processes. Innovations in material flow control systems are boosting productivity and slashing the risk of blockages:

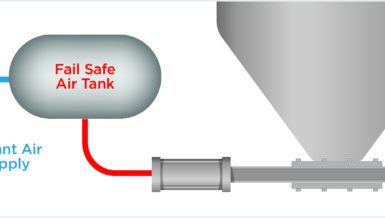

- Vibratory and Air Fluidizers: These devices use mechanical vibrations or compressed air to prevent bulk materials from adhering to silo and container walls, guaranteeing a consistent flow.

- Flow Aids and Liners: Innovative liners and flow aids minimize friction and promote the flow of even the most challenging bulk materials, warding off material buildup and flow interruptions.

- Discharge Gates and Valves: Advanced gate and valve designs allow precise control of material discharge rates, reducing waste and increasing process efficiency.

Automation and Robotics

Automation is increasingly prevalent in dry bulk storage facilities, yielding safety and efficiency dividends:

- Robotic Material Handling: Automated robots are deployed for material loading, unloading, and palletizing tasks. These robots enhance accuracy, cut labor costs, and elevate workplace safety.

- Automated Inventory Management: Advanced inventory management systems employ robotics and sensors to oversee material levels, reorder supplies, and optimize inventory turnover.

Safety and Risk Mitigation

Safety is a paramount concern in material handling, and innovations in dry bulk storage technology are tackling risks and enhancing workplace safety:

- Dust Control and Ventilation: Enhanced dust control systems and improved ventilation technology curtail the risk of dust explosions and safeguard worker health.

- Structural Health Monitoring: Continuous monitoring of storage structure integrity identifies potential issues early, thwarting catastrophic failures and ensuring workplace safety.

Customization and Design Software

The demand for customized storage solutions is on the rise, and innovative design software facilitates tailor-made designs:

- CAD and 3D Modeling: Computer-aided design (CAD) software and 3D modeling tools empower engineers to craft precise and customized storage solutions that align with unique project requirements.

- Simulation Software: Simulation software aids in optimizing the layout and design of storage facilities, guaranteeing efficient material flow and minimal material degradation.

Conclusion

Innovations in dry bulk storage technology are reshaping material handling across diverse industries. Advanced materials, IoT-enabled monitoring, sustainability-driven solutions, and automation collectively drive storage facilities’ efficiency, safety, and environmental responsibility. As the demand for efficient and sustainable material handling continues to surge, these innovations will remain pivotal in the future of dry bulk storage technology. They ensure the seamless flow of materials while reducing operational costs for industries on a global scale.