POLİMAK manufactures a wide variety of flow control and diverter valves designed for handling dry bulk materials in both pneumatic conveying and gravity flow systems, suitable for both horizontal and vertical flow directions. Along with our standard product range — including butterfly valves, slide gate valves, flap-type valves, pinch valves, iris valves, and flexible-tube diverter valves — we produce custom-designed valves for a variety of applications across sectors such as cement, energy, and food, for sticky, elastic, fragile, abrasive, and other specialized products.

We offer the following options in the design and manufacture of diverter and flow control valves customized to customer needs:

Our valves can be operated using various drive options, depending on process needs and automation level:

- Manual handle: Simple to use and cost-effective, this option works well when automatic control isn’t necessary.

- Pneumatic actuator: A durable air-driven unit that provides exact control and high force output, commonly used in heavy-duty equipment.

- Pneumatic piston: Designed for linear motion, the pneumatic piston provides rapid and powerful actuation and performs reliably in systems requiring quick response and stable performance.

- Electrical actuator: Driven by an electric motor, this system provides automated control, suitable for applications needing accurate positioning and integration with digital systems.

Our diverter and flow control valves are available in a broad range of construction materials tailored to different industrial needs:

- Standard Construction Materials

- Cast steel: Offers high strength and durability for heavy-duty applications.

- Cast aluminum: Provides a lightweight option with good corrosion resistance.

- Welded steel: Suitable for custom designs and structural robustness.

- Sanitary and Food-Grade Models

- Stainless steel: Ideal for food processing, pharmaceutical, and other sanitary applications due to its easy-to-clean, non-corrosive properties.

Wear-Resistant Options

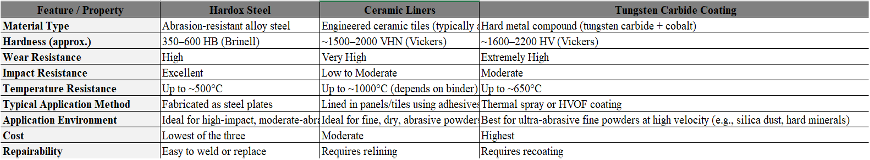

Custom-designed diverter valves can be equipped with various wear-resistant solutions to extend service life and maintain performance in abrasive bulk solid handling environments. The choice of material depends on the type of bulk material, flow characteristics, and system wear demands.

- Hardox Steel: A high-strength, abrasion-resistant steel ideal for handling coarse, high-impact materials such as clinker, sand, or crushed minerals. Its toughness and durability make it well-suited for demanding environments where mechanical impact is frequent.

- Ceramic Liners: High-purity ceramic tiles offer excellent resistance against fine particle abrasion and erosion. Commonly used for dry, abrasive powders like fly ash or alumina, they are ideal in low-impact areas of the material flow.

- Tungsten Carbide Thermal Spray Coating: A dense, extremely hard surface layer applied using thermal spray technology. This coating provides superior protection in high-velocity, highly abrasive applications such as pneumatic conveying of silica or ground minerals, where maximum surface durability is required.

- In addition to the more common 2-way and 3-way outlet valves, we also design and manufacture multiport diverter valves, enabling the conveying of bulk material from a single feeding point to multiple receiving points. Besides, depending on customer requirements, we produce flexible tube diverter valves. This valve features a flexible tube that maintains a consistent cross-sectional area, resulting in minimal pressure drop and a reduced risk of cross-contamination thanks to its adaptable design.

- Diverter and flow control valves produced in accordance with ATEX regulations and directives are designed for safe operation in explosive atmospheres where combustible dust may ignite. Built in compliance with EU directives 94/9/EC and 2014/34/EU, these valves feature explosion-proof motors, ATEX-certified actuators, and low-friction components to prevent sparks, heat, and static discharge. They help ensure safety in processes involving flammable materials such as flour, coal, and aluminum.

- High-temperature gravity discharge valve models, designed to operate reliably at temperatures up to 200°C, are used across various industrial sectors such as cement, mining, food processing, chemical, and power generation. They are ideal for handling bulk materials such as clinker, fly ash, cement powder, sand, minerals, grains, and other high-temperature material.

- Built-in, replaceable polyurethane or silicone seals are used to effectively prevent product leakage during operation. The type of seal is selected based on specific application requirements, providing strong resistance to wear, temperature, and chemical exposure depending on the material chosen.

- Our custom-made diverter and flow control valves can be equipped with built-in limit switches and position indicators to enable accurate monitoring of valve position.

- Flow distribution between two outlets is managed by adjusting the diverter flap with the help of a custom position controller. This allows operators to control the amount of material directed to each outlet.

- We export our products to continents worldwide. Flanges are available in both European (DIN) and American (ANSI) standards, offering versatile options for various applications.

- Inlet and outlet flanges of the bulk material conveying system may be either rectangular or circular in form. Both types of valves are available in our product portfolio.

- An optional side inspection door is available, allowing easy access for maintenance, cleaning, and internal inspection without dismantling the entire system.

- The design can include a side inspection door to allow quick and convenient access for maintenance, cleaning, and system checks.

With 45 years of expertise in bulk material handling, POLİMAK continues to deliver reliable and innovative solutions tailored to evolving demands of the industry.

Our custom-designed diverter and flow control valves meet the needs of various industrial plants by providing dependable, versatile, and easy-to-use solutions. From various drive options — manual, pneumatic, or electric — to construction materials — such as cast steel, cast aluminum, stainless steel, and wear-resistant options like Hardox — our valves are designed to meet diverse industrial needs, making them ideal for applications ranging from sanitary environments to extreme wear and high temperatures, and ensuring each valve meets specific process requirements.

Also enhanced with ATEX compliance, optional position indicators, and convenient maintenance features such as side inspection doors, our valves ensure both safety and efficiency in a wide range of industrial applications worldwide. POLİMAK provides solutions that integrate seamlessly into your bulk material handling systems — designed to raise performance, reliability, and efficiency.