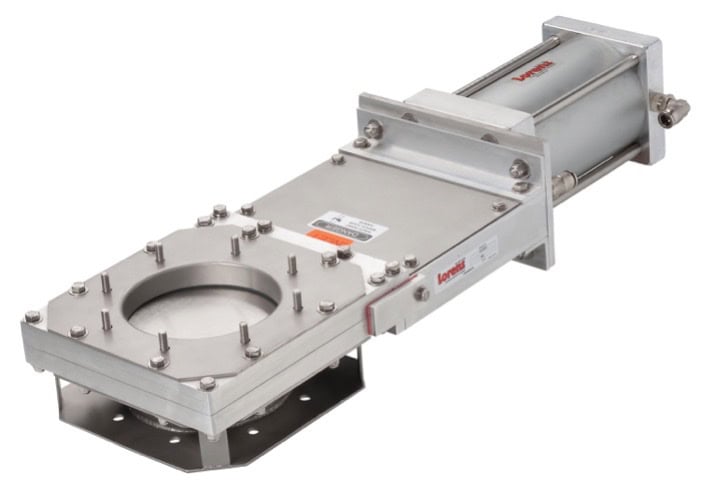

The square machined blade “dead ends” against the body of the valve allowing material to escape below.

The Discharge Valve seals top to bottom to a maximum of 15 PSI. Typically, the valve is installed between a bin or hopper and a rotary airlock.

Product flow from the bin above can be controlled without shutting off the rotary airlock.

The Discharge Valve will vent air only (not product) from the perforated steel on the bottom of the valve. As an option the valve can be air purged to prevent any venting of air.

Our Discharge Valve can cut through a standing column of material without using a Special Service Inlet.

Lorenz manufactures a full line of comprehensive pneumatic products ideal for material conveying and bulk handling systems.

Discover the difference with Lorenz Conveying Products—your one source for material handling excellence.

905-372-2240 | lorenzproducts.com