Whether you’re operating in food & pet food, plastics & packaging, grain milling, or chemical processing, this slide gate is engineered to shut off dry bulk conveying lines running under vacuum, dilute phase (up to 15 PSI), or gravity flow—safely and efficiently.

Purpose-Built for Performance

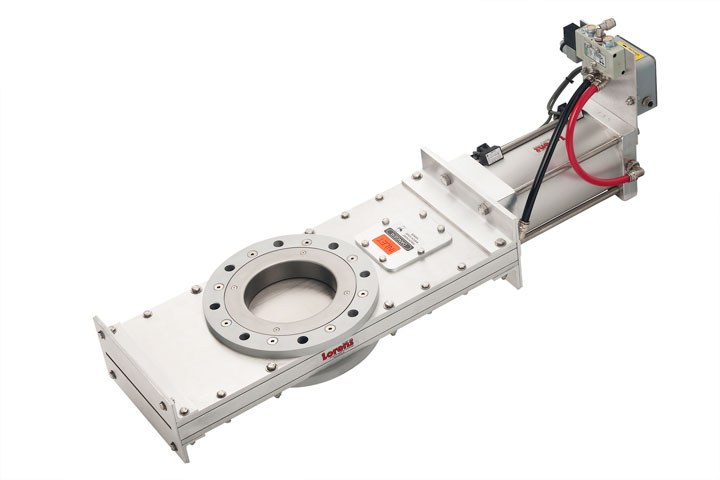

The BBH Slide Gate is designed with versatility in mind and can be installed horizontally or vertically (for vacuum and pressure lines). Its lightweight aluminum frame combined with robust contact materials—aluminum, carbon steel, or stainless steel—makes it a strong fit for a wide range of system requirements.

With sizes ranging from 1.5″ OD to 14″ OD and a variety of inlet/outlet configurations—including TPS (Tube & Pipe Stubs), LSP (Lightweight Stud Pattern), SB (Stud Bolt 150 lb. pattern), BBH (Blind Bolt Hole 150 lb. pattern), and BTV (Bolt Through Valve)—you get a highly adaptable component that integrates seamlessly into your existing setup.

Built for Control and Durability

The BBH Slide Gate features a stainless steel blade, paired with a PBL (Positive Blade Lock) that secures the blade between the actuator and the valve body. This means enhanced blade stability and reliable shutoff with every cycle.

The design supports unobstructed flow, helping to maintain product integrity by eliminating degradation and ensuring efficient transfer. Plus, the gate is temperature rated to 82°C (180°F), with high-temperature kits available for more demanding applications.

Actuation That Fits Your Process

From fully automated to manual operations, the BBH Slide Gate gives you options:

- Pneumatic

- Electric

- Manual hand lever

- Hand crank

- Hand wheel

- Chain wheel

And with an oversized air cylinder, you get the power you need to move the blade—even under heavy product flow—without compromising speed or control.

Why Choose Lorenz Slide Gates?

Robust Construction – Built to handle continuous blade cycling and demanding environments.

Flexible Integration – Multiple configurations and materials to suit your system.

Reliable Shutoff – Prevents product loss and contamination during maintenance or downtime.

Engineered for Longevity – Reduce maintenance and replacement costs over time.

At Lorenz Conveying Products, we don’t just manufacture components—we build solutions. The BBH Slide Gate is another example of how we deliver performance-driven innovation for dry bulk conveying systems.

Have a system challenge?

Let’s talk gates that seal, last, and deliver.