COMAV’s History

COMAV is an Italian company with a long tradition and experience in the field of industrial components, in the bulk handling sector and in the materials processing industry. Founded in the 80s, the company has always placed innovation and quality at the heart of its production philosophy. Over the years, COMAV has specialized in the design and construction of compaction machinery, becoming an international point of reference. Thanks to a team of highly qualified engineers and constant investments in research and development, COMAV has been able to anticipate market needs, proposing effective and sustainable solutions.

What is EPS?

EPS, known as expanded polystyrene, is a lightweight and versatile material used for packaging and insulation. Its closed cell structure offers excellent insulating properties and shock-absorbing capabilities. However, once used, EPS causes a significant problem: waste management. Its volumetric and lightweight nature takes up a lot of space in landfills, contributing to environmental pollution.

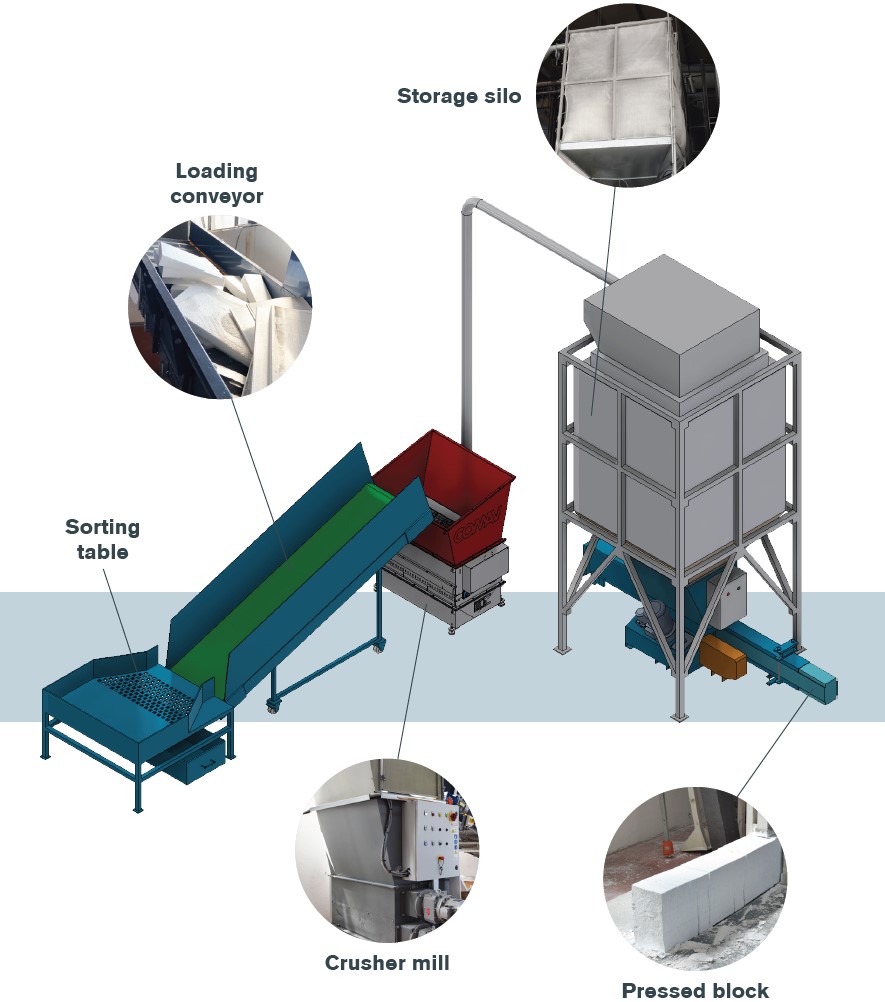

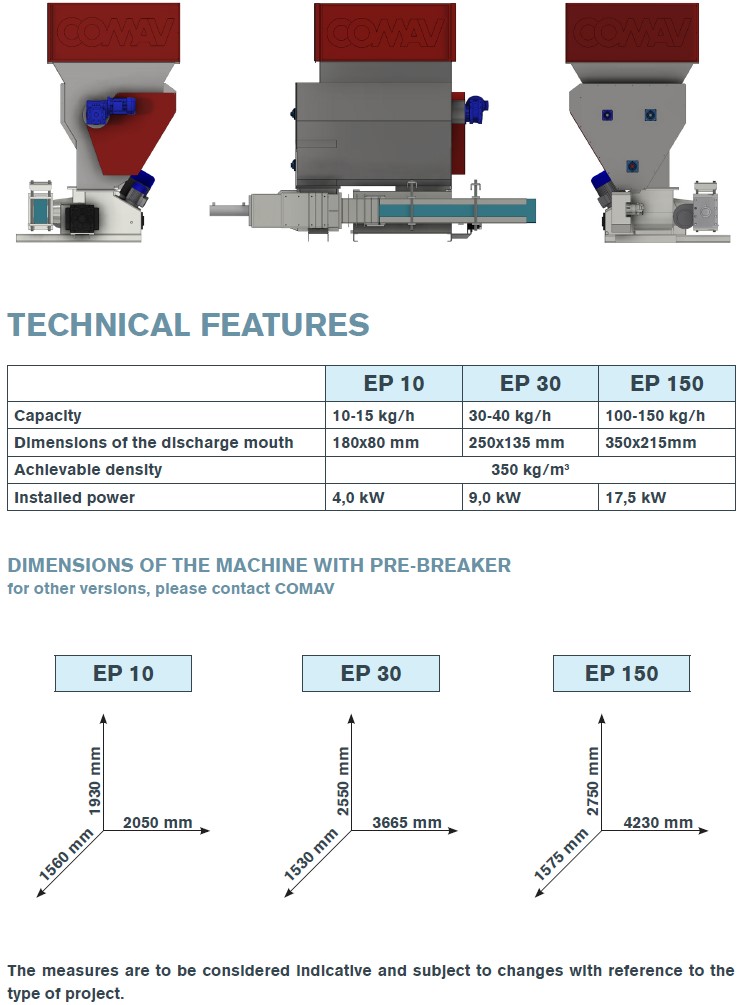

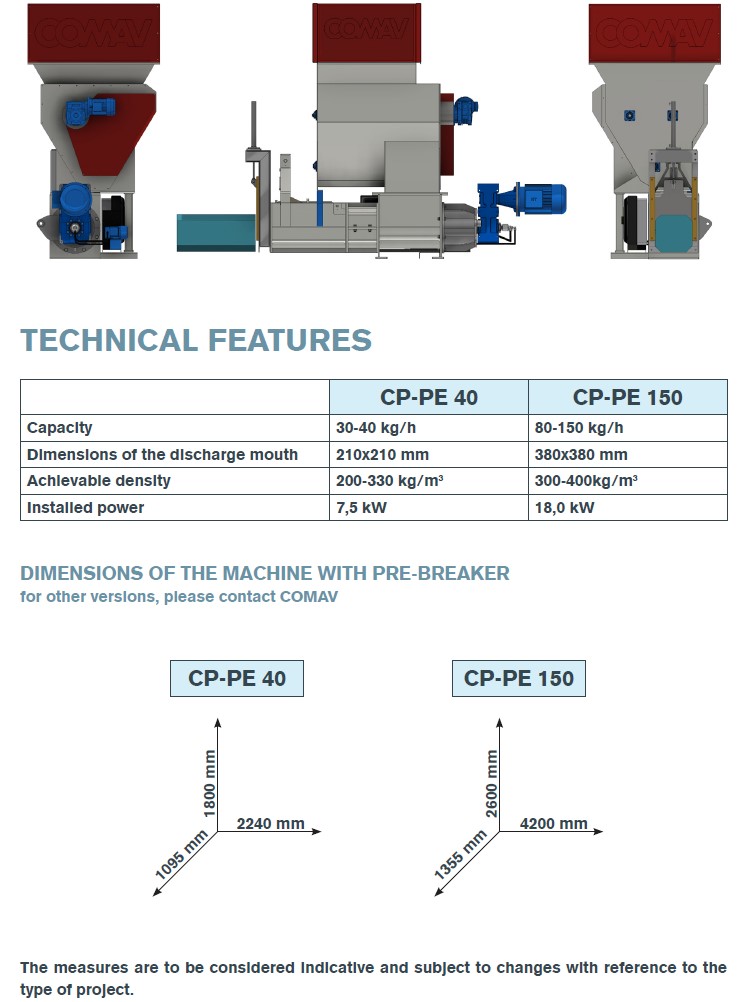

OUR COMPACTORS EP and CP-PE: Technology and Innovation

COMAV’s compactors are equipped with compaction systems that reduce the volume of EPS by an average ratio of 40:1 and the density by a proportion of 28:1. This means that large quantities of expanded polystyrene can be compacted into small blocks, making transport and storage easier. This process not only frees up valuable space in landfills, but also reduces the costs associated with transporting recyclable materials.

Advantages of COMAV’s EPS Compactors

- Volume Reduction: The ability to reduce the volume of EPS with an average ratio of 40:1 and density of 28:1 allows for significant space saving.

- Energy Efficiency: The compactors are designed to be energy efficient, using advanced electric motors with minimal energy consumption in compliance with the new Energy Transaction Decrees.

- Ease of Use: They are easy to use and require minimal maintenance, making them ideal for businesses of all sizes.

- Quality of the Recycled Material: They ensure that the compacted polystyrene retains its properties, making it suitable for various industrial sectors.

- Economic and Environmental Sustainability: They contribute to the reduction of waste in landfills and generate economic opportunities by selling the compacted polystyrene.

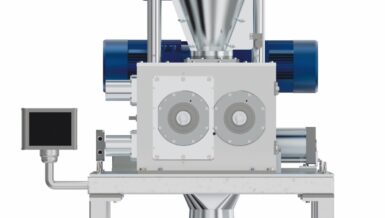

Complete Recycling Plants

In addition to EPS compactors, COMAV also manufactures complete plants that include conveyor belts, grinders and silos, offering integrated solutions for the management of expanded polystyrene. These plants are designed to optimize the entire recycling process, from material collection to final compaction. Conveyor belts facilitate the movement of the material through the various stages of the management, while grinders further reduce the size of the polystyrene, preparing it for compaction. Finally, the silos offer safe and organized storage of the handled material.

The Role of EPS Compactors in Recycling

COMAV’s EPS compactors transform a problematic material into a valuable resource. Once compacted, the expanded polystyrene can be easily transported to recycling plants to be reused in new products. This process reduces the need for virgin raw materials, contributing to a sustainable circular economy. The implementation of these compactors represents an important step for many industries in achieving sustainability goals, improving operational efficiency and reducing environmental impact.

Conclusion

The EPS compactors manufactured by COMAV represent an innovative and sustainable solution for the recycling of expanded polystyrene. Due to their ability to significantly reduce the volume of the material, these compactors offer numerous benefits, including space saving, energy efficiency, ease of use, and recycled material quality. In a world increasingly aware of the need for sustainable practices, the technologies developed by COMAV are key to addressing environmental challenges and promoting a circular economy.