COMAV’s SVR DEPA bag emptying machine model has been designed to ensure versatility and safety when emptying any type of bag. This model is also ATEX 20/22 certified, making it suitable for use in potentially explosive environments caused by the presence of combustible powders.

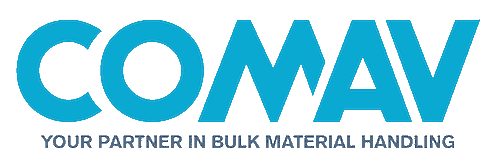

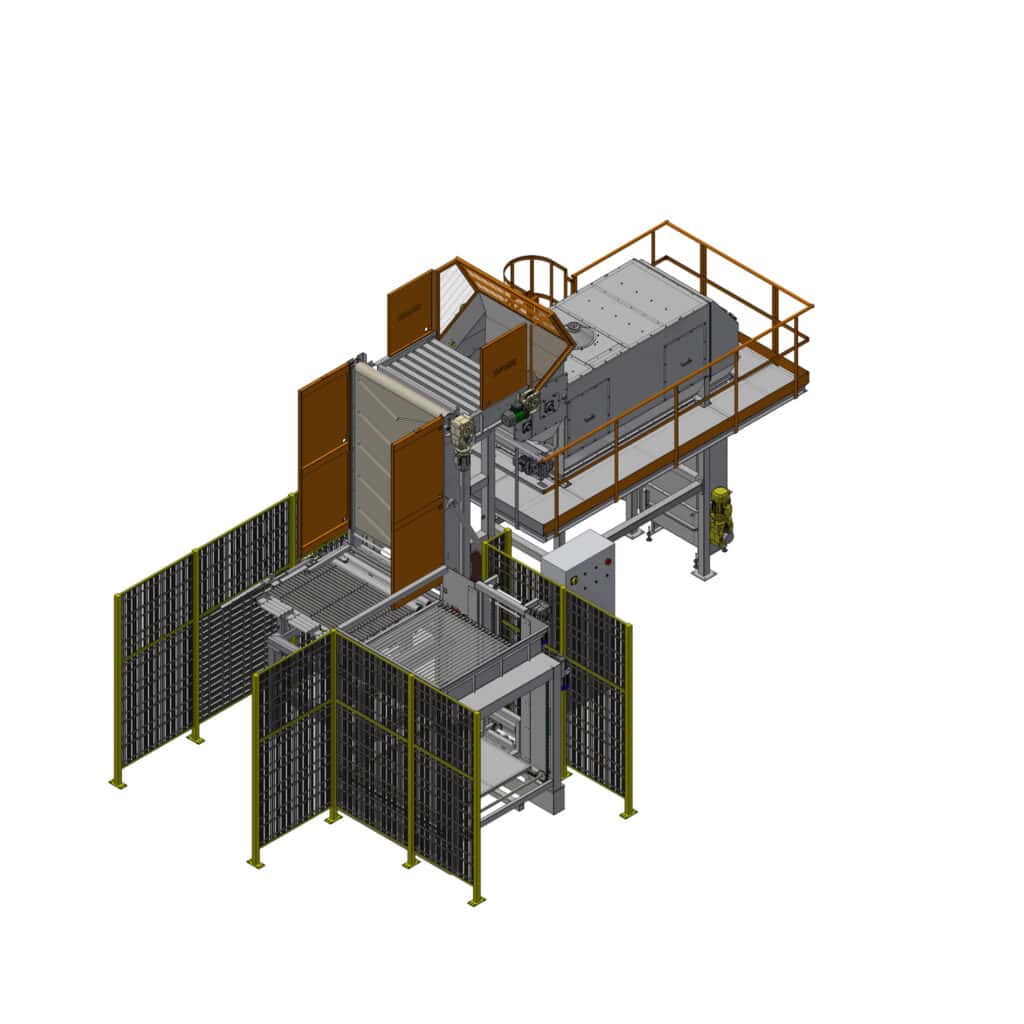

The pallet is loaded by forklift and the loading station can be located frontally or laterally. After the bag emptying cycle is complete, the operator must remove the empty pallet before another cycle can begin. It’s possible to achieve higher levels of automation with the models ELITE and DELUXE.

The SVR DEPA ELITE is equipped with a totally electric, non-hydraulic roller shutter empty pallets magazine. This overlapping system allows the management of all types of pallets regardless of the state of wear and configuration, eliminating any blind corner and avoiding any operator risk.

The SVR DEPA DELUXE not only features an empty pallet management technology, but also comes with a full pallet magazine, a station equipped with conveyors that transport the full pallets to the tilting table. This system was designed with the aim of improving the handling of pallets, which are commonly in a damaged state as a result of transportation by trucks or by sea. The roller conveyors ensure smooth and linear movement, preventing any accidents caused by incorrect translocation.

The correct positioning of the full pallet is managed by a Muting concept able to identify the object that has been placed on the full pallet magazine. This system also guarantees the safety of the operator by initiating a safety procedure that stops the entire emptying process in case of attempted safeguards bypass.

To increase effectiveness and safety, the SVR DEPA model can be equipped with the following components:

- An advanced filtration system that captures the finest particles of dust. This system not only protects operators, but also the working environment, and reduces the risk of cross-contamination between different batches of materials.

- The machine is made of high-quality construction materials, such as: carbon steel with parts in contact with the product in stainless steel or, entirely in stainless steel (in accordance with EC1935/2004) ensuring long service life and material management that requires certification for food use.

- An intuitive user interface that allows operators to easily control and monitor all machine functions. This reduces training time and minimizes operational errors.

- The machine can be integrated with industrial automation systems, allowing centralized management and the optimization of production processes.

- Our SAVE MONEY technology for the management of empty bags is seamlessly handled without the need for any operator involvement. To handle empty bags, a dedicated mill is installed at the end of the pre-dosing auger inside the machine body. This mill efficiently chops up the bags, enabling the option to incorporate them back into the re-granulation line. There’s also the possibility to gather the remaining bag flakes and transfer them into a suitable container, like a Big Bag, to be sold at market rates.

A Hydraulic Press or a Pressing Screw complete the solutions for the management of empty bags. Our hydraulic manual tying press can compact up to 1000 empty bags per meter, whereas our pressing screw is ideal for smaller production quantities.

- A product traceability management system using a barcode reader or an augmented reality viewer to automate the product loading, unloading and traceability cycle, and verify input and output weights.

- A video camera to monitor the blades’ state of wear and check the status of the working area.

- A 3D vision system that allows the operator to interface with our service and manage maintenance problems remotely.

- Our rotary and diverter valves for pneumatic transport and management of the silo loading process through a specific software.

The SVR DEPA bag emptying machine is used in various industrial sectors thanks to its versatility and safety. A few sectors are plastic, food, and chemical.

In the production of plastics, the management of raw materials such as polymers, resins and additives is crucial. The SVR DEPA model empties bags containing these materials efficiently and safely, preventing dust dispersion and ensuring a clean working environment. The ability to treat both powders and granules makes it ideal for different stages of the plastic production process, from the preparation of mixtures to the production of granules or finished products. In the food industry, the SVR DEPA model is used to treat a wide range of powder and granule ingredients. For example, it can be used to empty bags containing flour, sugar, cocoa powder, spices, and other essential ingredients for food production. The ATEX certification ensures that these operations take place in total safety, preventing the risk of explosions due to the presence of combustible dust. The chemical sector is another area where the SVR DEPA finds wide applications. This bag emptying machine is ideal for handling powdered chemicals, such as carbonates, caprolactam, pigments (carbon black) and raw materials, for the production of various chemical compounds. The ATEX certification is particularly important in this area where chemicals can create explosive atmospheres.

The SVR DEPA bag emptying machine offers numerous competitive advantages:

- Increased Productivity: The speed and operational efficiency of the SVR DEPA makes the production processes quicker, increasing the amount of product treated in a certain time interval.

- Reduction of Operational Costs: The ability to operate efficiently and the reduction of machine downtime, due to easy maintenance, contribute to reducing the overall operating costs.

- Improved Safety: ATEX certification and advanced filtration systems ensure a safe working environment, reducing the risk of accidents and protecting the health of operators.

- Versatility: The ability to handle a wide range of materials makes the SVR DEPA a versatile solution suitable for different industries and applications.

In conclusion,COMAV’s bag emptying machines represent a technologically advanced and safe solution for handling powder and granule materials. With the ATEX 20/22 certification, versatility, and operational efficiency, the SVR DEPA is an ideal choice for industries looking to improve their productivity while maintaining high safety standards. With its ergonomic design and easy maintenance, this machine proves to be a smart investment for companies that want to remain competitive in an increasingly demanding market.

COMAV s.r.l, with its extensive experience and commitment to innovation, continues to provide solutions that meet customers’ requirements, ensuring reliable and excellent performing machines. The SVR DEPA model is a perfect example of how the company manages to combine advanced technology, safety, and efficiency in a single product, contributing to the success of companies in various industrial sectors.