This article focuses on the differences in meal mixes for pet food and aqua feed production and what type of knowledge testing the product will generate. Testing of two material types: pet food – dog and aqua feed – salmon was done to argue why a gravimetric feeding system is preferable when working with mixed meal types.

Testing and Results

Four types of tests were performed in the Jesma test laboratory: bulk density, angle of repose, particle size, and moisture content.

Bulk density can interfere with powder flow, large variations between loose and tapped bulk density may signify a poorer flowing material. Using the compressibility index for measuring the bulk density it shows for pet food – dog 20,47 % indicating a passable flow character and for aqua feed Salmon 22,89% also indicating a passable flow character placing both materials (food and feed) around the middle of the scale for testing. Further analysis of the material using Angle of Repose testing indicates a fair flow property for the dog food but indicates possible hang-ups for salmon feed, these possible hang-ups are considered when recommendations for best-suited equipment are given.

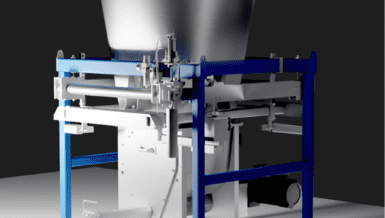

Testing the materials indicates the behavior and flow properties of the given products. These tests are used to ensure the best possible accuracy when choosing the type of equipment. In this case, Jesma recommends due to the large variations between the loose and tapped bulk density using a gravimetric system, which will be able to operate with dosing and flow accuracy of +/- 0,5 % independent of variations in recipe and bulk density as opposed to a volumetric system, which will be able to operate with a flow variation above 15%.

To ensure continuous production, the following recommendations are given based on the testing done on the Pet food and the Aquafeed:

- The pre-bin feeding the extruder/ pellet mill should be able to hold at least 1½ of the batch.

- Production time of 5-10 min is preferable.

- Should be equipped with an agitator to prevent hang-ups (this is most critical in the case of Aqua Feed)

Why test your product?

Testing enables product knowledge, knowing about flow properties, changes in density, and the like, allows design adaptions according to the physical properties of the product. For example, choosing the type of bin or silo best suited for the given type of product. Testing means equipment designed for your specific needs and Jesma can assist in both testing