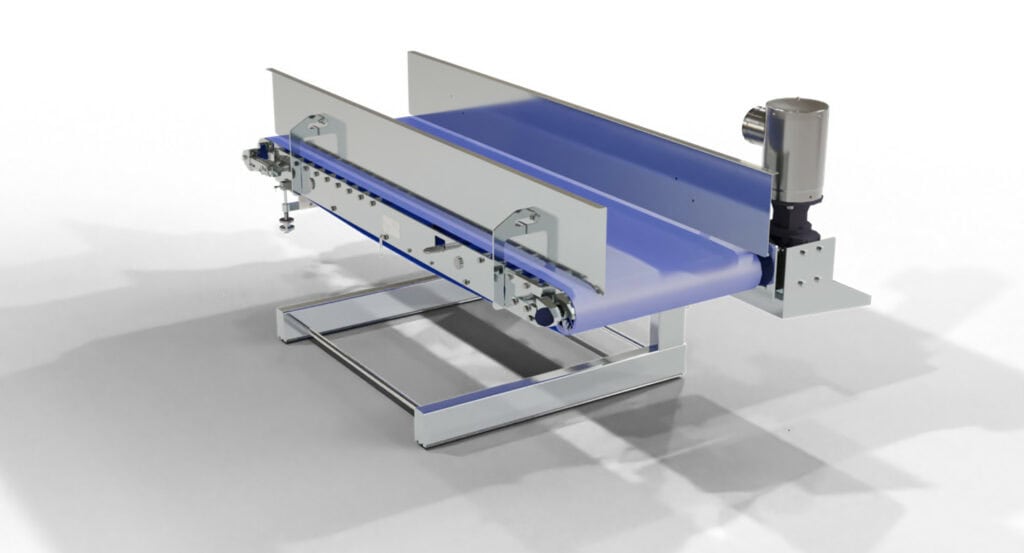

The MWF-OS self-cleaning pulley eliminates material build-up and belt-tracking problems. Its unique product containment skirt design prevents material spillage and assures proper feed control. The rigid scale support system provides exceptional stability that survives aggressive sanitation practices, maintaining accuracy without frequent re-calibration.

A standard design coupled with dimensions and rates tailored to each application adds versatility to its capabilities. Its design for ease of maintenance and the ability to be economically reconfigured to align with future capacity needs provides a long-term, low cost of ownership.

Features

- Handles a wide range of materials and densities

- Sanitary, stainless construction

- Simplified conveyor assembly provides positive belt tracking and uniform belt tension eliminating the need for belt tracking and tensioning devices.

- Easy access, low maintenance design, no tools disassembly to support basic sanitation

- Excellent accuracy and stability

- Rugged construction – built to survive

- Cantilevered frame for fast belt removal

What is your definition of “sanitary”?

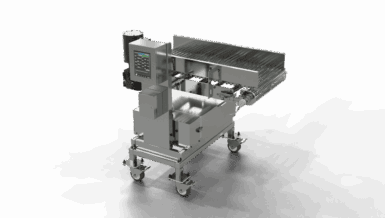

The MWF-OS is available with different weld and surface finishes and various component Ingress Protection (IP) ratings to meet all operating conditions and budgets. The MWF-OS features commercially available drive components, enabling greater flexibility regarding replacement part purchasing decisions.

Speed sensor mounted at idling pulley

Measures the true speed of the belt via rotation of the idling pulley, not an inferred belt speed based on motor speed. Belt slippage or breakage is immediately detected.

Automated calibration

Zero calibrations can be manually initiated by an operator, remotely from a host supervisory control system, or automatically whenever the measured load drops below a pre-programmed tolerance. During span calibration, Thayer Scale’s optional automated test weight placement system transfers a precision test weight to and from its storage position to the scale enabling complete automatic calibration.

Full-length adjustable product containment skirts

Height adjustable gap gradient from the infeed end of the weigh belt to the discharge prevents particle jamming of material between the skirts and the belt. Available sealing strips at the infeed transition provide a second layer of material containment preventing spillage.