By reducing the proportion of clinker, the cement industry aims to drastically cut CO₂ emissions in production. Cement manufacturers are therefore increasingly turning to additives such as granulated blast furnace slag, fly ash, calcined clay, recycled concrete and others. However, the different raw materials must be fed and blended in exact proportions to ensure the desired product quality. With the now expanded TestCenter in Darmstadt, Qlar offers perfect conditions for simulating such process steps and working with customers to validate the ideal material composition for the desired product result. ‘With the expansion of our TestCenter to include blending trials for sustainable cement, we are marking a decisive step forward in the development of environmentally friendly building materials,’ explains André Appel, Head of the TestCenter in Darmstadt. ‘Our goal is to take a leading role in the implementation of solutions and the validation of clinker substitutes in order to significantly reduce CO2 emissions in cement production.’

Precise measurements and blending tests

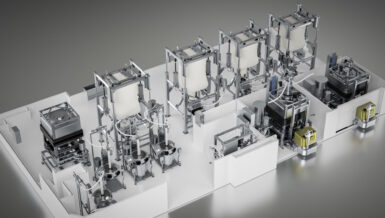

The new closed loop system at the TestCenter allows different products to be combined and accuracy tests to be carried out using different measuring principles. At the heart of the new tower setup are the MULTICOR S mass flow meter and LIW Feeder MET screw feeder. MULTICOR S can measure bulk quantities of up to 7 t/h in the closed loop. Based on the Coriolis principle, this technology delivers high-precision measurements with an accuracy of ±0.5%, even with bulk material of different particle sizes. When combined with the LIW Feeder MET screw feeder, two-component processes can be simulated. The rotation of the MULTICOR measuring wheel causes an initial mixing of the materials. Various materials can be mixed in different ratios in the TestCenter. The customer analyses the resulting material samples and can use the results to fine-tune their production process.

‘The weighing, feeding and pneumatic conveying test stations already available at our TestCenter have now been meaningfully extended,’ says Karsten Grünewald, Head of Sales Infrastructure at Qlar. ‘Our customers benefit from simplified processes for evaluating new material combinations, dosing concepts and applications in order to make their cement production more sustainable.’ An initial test run with material from an international manufacturer has already been successfully completed, and further test series are in preparation.

In addition to its location in Germany, Qlar operates other specialised test and innovation centres to support customers worldwide in process optimisation. While the TestCenter in Prague, Czech Republic, focuses on the processing of alternative fuels for the cement and recycling industries, pneumatic conveying and injection systems are tested at the Doncaster site in the United Kingdom.

Further information at www.qlar.com/services/testing