In collaboration with industry leading companies and its talented team, MTS is proud to help supply millions of Americans with vaccines.

As high-volume distribution continues, never has dry ice played a more critical role than the one it plays in maintaining the vaccine’s integrity during transportation. Tapped to design and build customized equipment that dispenses dry ice into temperature-controlled containers, MTS worked faster than ever before. Leveraging the talents of its experienced and committed team, Material Transfer produced discharging systems in just eight weeks.

“To design and build customized equipment in an accelerated timeframe, requires a level of knowledge we are fortunate to have on our team,” said Scott Nyhof, president of Material Transfer. “With lives on the line, our team worked tirelessly to deliver these systems in record time, and I couldn’t be prouder.”

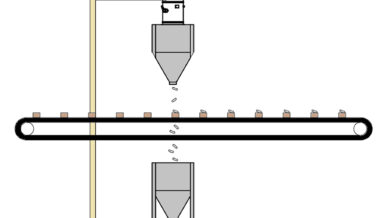

No stranger to the complexities associated with custom design and build programs, Material Transfer built a customized system that addresses dry ice discharging challenges. The system includes a customized crusher that sizes the ice for proper flow and filling of the shipping boxes, and Eriez 65B electromagnetic feeder, and a scale system that monitors the weight of the ice being dosed into, and the total weight of the shipping boxes. Utilizing Manufacturing 4.0 and the IoT, MTS also equipped the systems to monitor and communicate all aspects of the machine’s operation to the customer for diagnostic purposes, to forecast issues, and prevent downtime.

“We have always held ourselves to a higher standard, believing that doing things right and serving others well are the most important things that we do,” said Nyhof. “And we are humbled to play a role in delivering the COVID-19 vaccine to millions of Americans.”