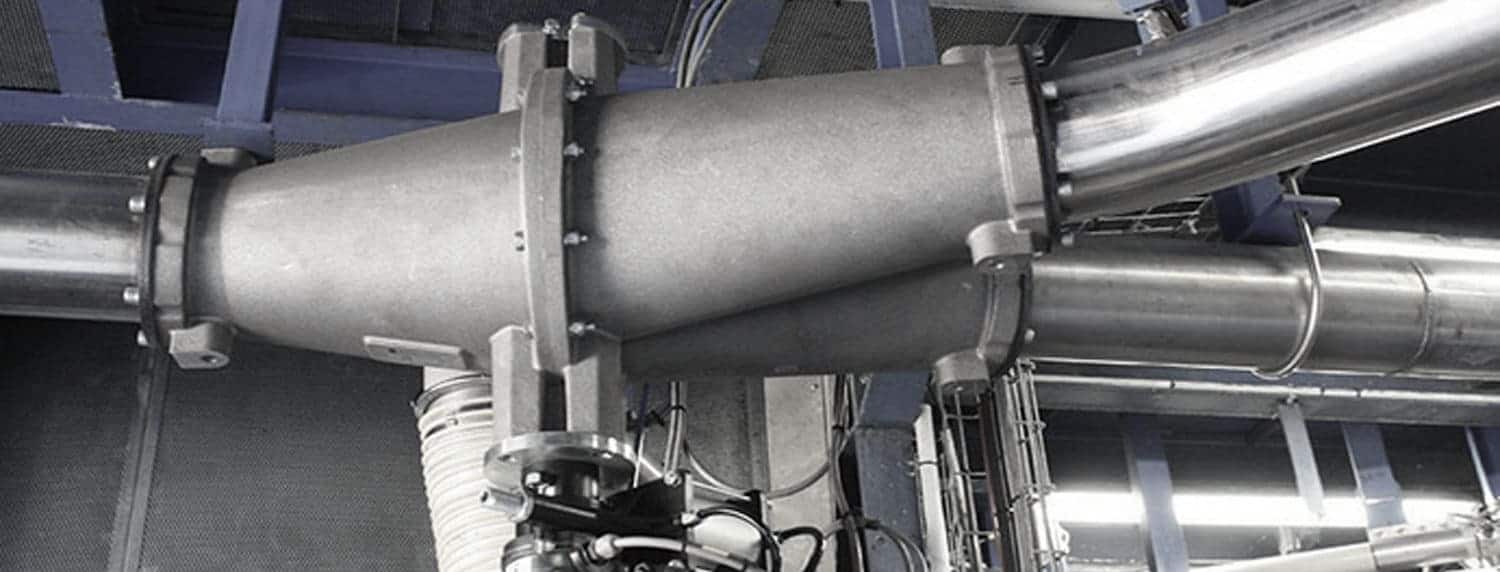

Powder valves have an application in varying industries, primarily the pharmaceutical and chemical industries, and are designed to handle solid materials. Powder valves rotate 180 degrees (counter)clockwise to break up and disseminate material through the valve to the following processing stage. Depending on the application of powder valves, a specific actuator is required that facilitates the rotation. The most common valves used in powder handling applications are butterfly valves, diverter valves, and rotary valves.

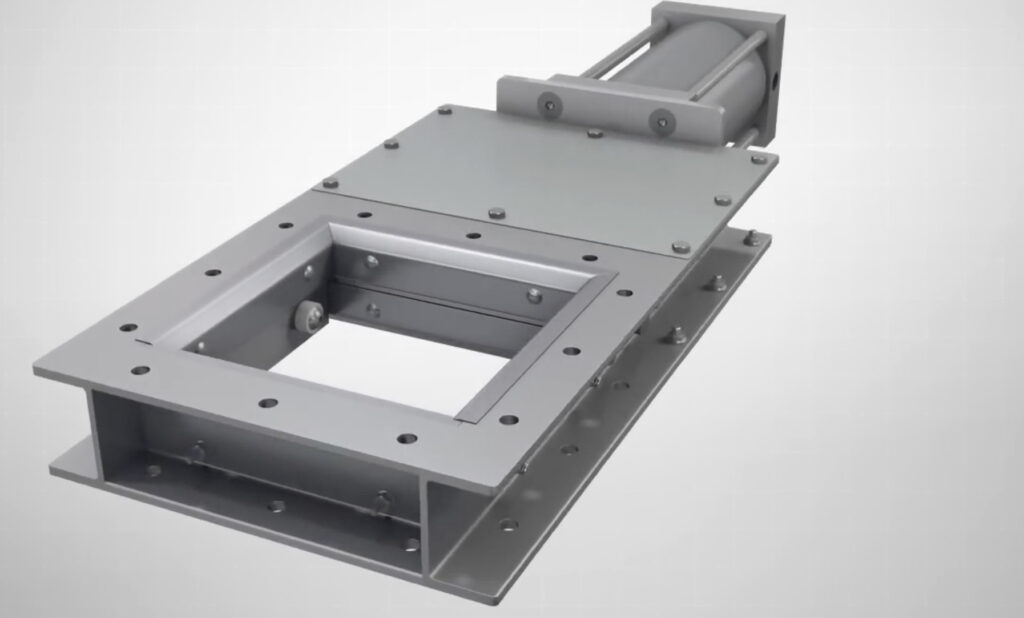

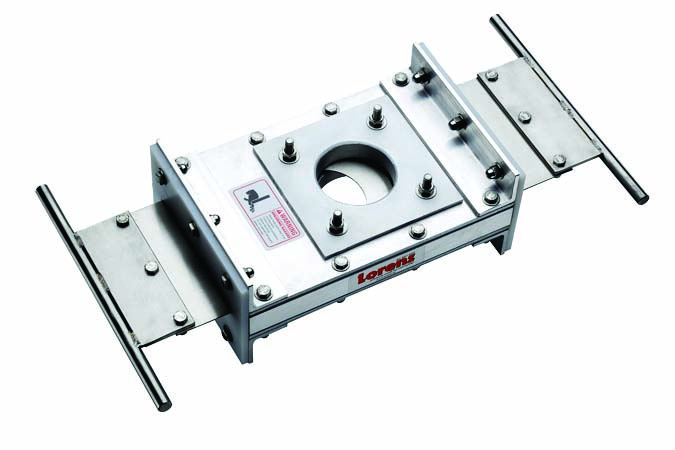

Butterfly valves: Butterfly valves regulate flow by starting, slowing, or stopping a fluid. A rotating disk is a mechanism used to control the flow by allowing the disk to close the valve intermittently. Butterfly valves are among the most desirable valve types because of their low cost and lighter weight.

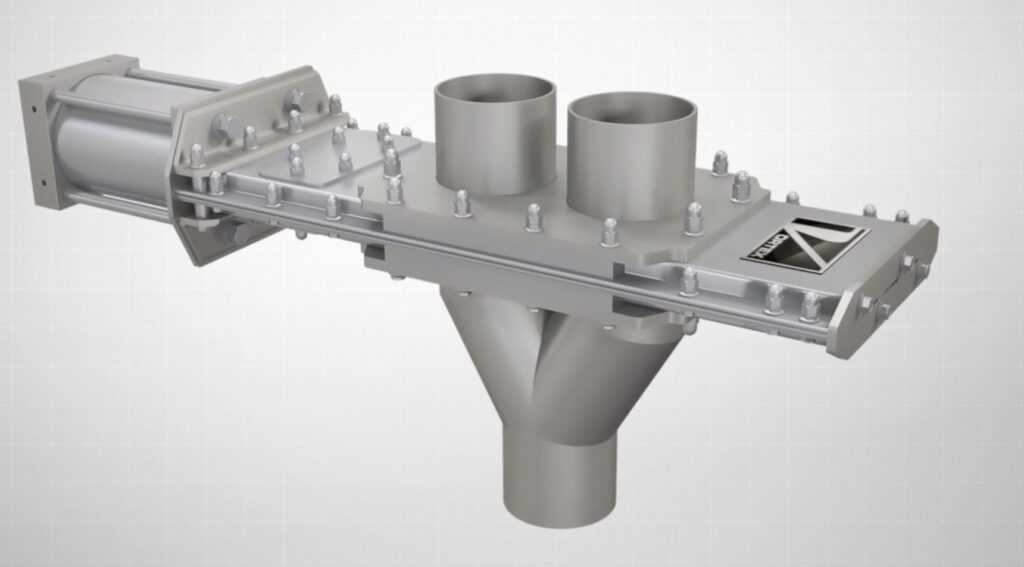

Diverter valves: Diverter valves are employed to convey powder amongst other materials to multiple destinations with care. Diverter valves are often required in dairy, food, and pharmaceutical application and therefore need hygienic standards for safe powder handling.

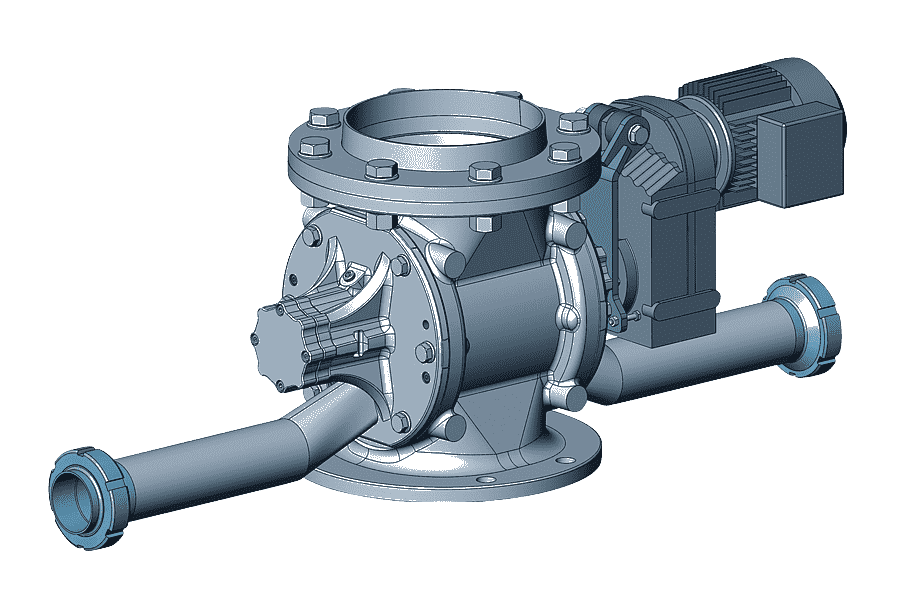

Rotary valves: Rotary valves find their primary usage in bulk material handling, dust collection, and pneumatic conveying. Rotary valves regulate the flow of material and create consistency to prevent leakage, damage to the valve, and jamming.