“Providing Cost-Effective Solutions to Industrial Problems”

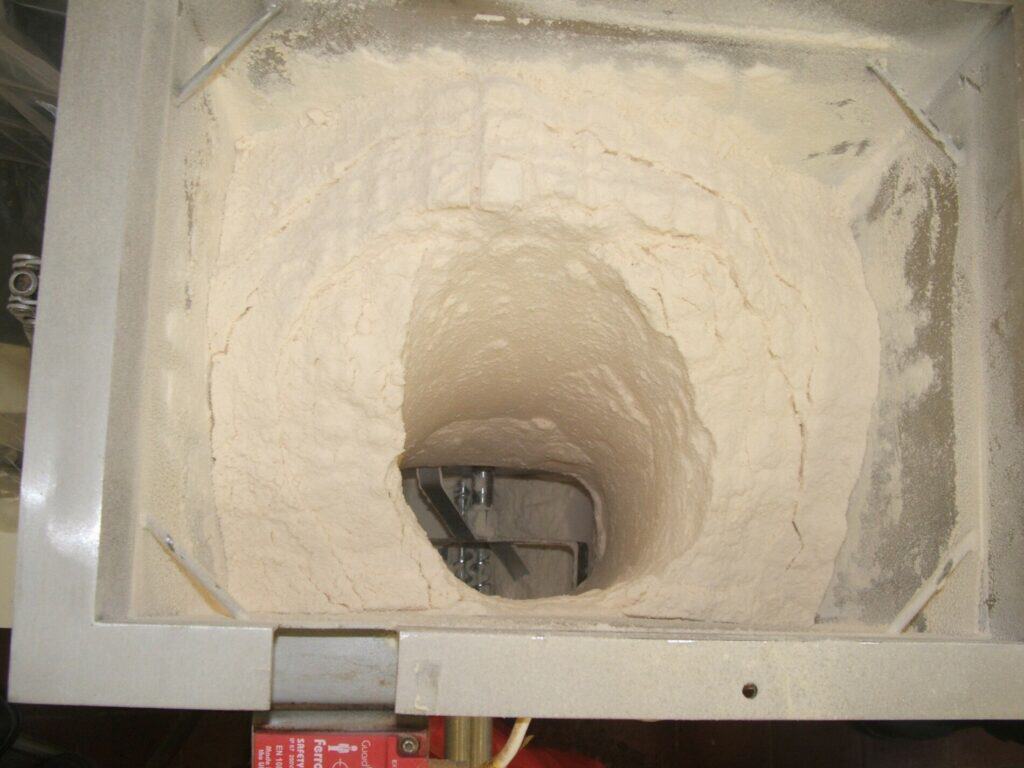

The Wolfson Centre for Bulk Solids Handling Technology is part of the School of Engineering at The University of Greenwich at Medway, Kent, UK and has specialised in solving materials handling problems since 1973. The Centre undertakes leading edge research into a wide range of problems associated with the handling and storage of granular and powder materials, including all grades of aggregates, alumina, cement, coal, flour, grains, pellets, plastics, sugars, starches, pharmaceutical powders and wood chips, to name but a few.

An important aspect of the work undertaken by The Wolfson Centre relates to its independent and impartial status. This enables the evaluation of plant schemes and recommendations for equipment types to be made based purely on the basis of suitability for the application.