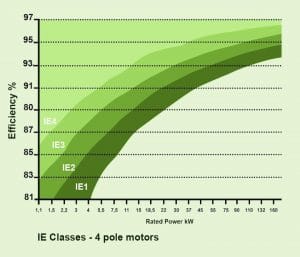

Published by the government and updated annually, the scheme is based on the ETL (Energy Technology List) – a managed list of energy-efficient plant and machinery, such as boilers, electric motors, and air conditioning and refrigeration systems (visit: https://www.gov.uk/guidance/energy-technology-list). For a product to be on the ETL, it must meet specific energy-saving or energy-efficient criteria. The Department for Business, Energy and Industrial Strategy (BEIS) annually reviews the technologies and products that qualify for inclusion, with the ETL being managed on behalf of BEIS by the Carbon Trust. The ETL forms part of the Enhanced Capital Allowance (ECA) tax scheme for businesses.

The ECA tax scheme means that a business can invest in energy-saving plant or machinery to provide accelerated cost savings, that might otherwise be too expensive. The first-year allowances let businesses set 100% of the cost of the assets against taxable profits in a single tax year. This means the company can write off the cost of the new plant or machinery against the business’s taxable profits in the financial year the purchase was made. An ECA is claimed through a business’s income or corporation tax return in the same way as any other capital allowance. HM Revenue and Customs are responsible for the tax-related aspects of the ECA scheme.

Commenting on the initiative, Spiroflow’s James Podevyn, said: “There has never been a better time to get government support for sustainable initiatives and as we all have our part to play in reducing our environmental impact, replacing old and obsolete plant and machinery, particularly motors, with energy-efficient models is an easy decision to make.

As an industry leader, it is important for us to encourage best practice where we can, which in this case is helping businesses achieve their sustainability targets without seeing a large dent in the bottom line. Given that this swap-out initiative is in the interest of all manufacturing and processing businesses, we would be more than happy to provide guidance and support where required.”