Spiroflow is a global leader in the field of powder handling and dry solids processing and an emerging leader in control systems integration. Throughout our 45-year history, our design engineers and process automation team have provided customers with the safest, most efficient, innovative and most reliable process solutions available.

Yes, we were an early inventor of the flexible screw conveyor, but we’ve grown significantly since those early days as have our products and service offerings. Spiroflow delivers engineered solutions designed to solve your greatest handling and processing challenges, whether it is a single conveyor or a complete powder handling system with integrated controls.

With our flexible screw, Aeroflow® aero mechanical, Cableflow® cable drag, Chainflow®, and Dynaflow® chain drag conveyors, hands down, we offer the widest range of mechanical conveyors for dry bulk solids and ingredients. Because we offer such a wide range of conveying methods, our engineers will evaluate your needs objectively so you receive the ideal conveyor for your application.

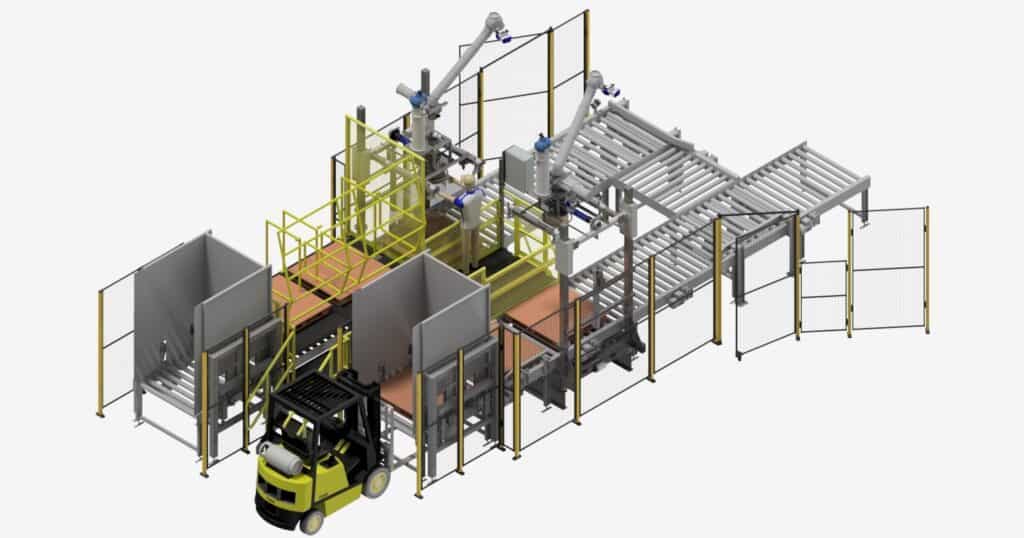

We are also known for our expansive line of Spirofil® bulk bag fillers, bulk bag unloaders, control systems, bulk bag conditioners, custom-designed hoppers, bin activators, and bin, bag, box and drum emptiers, end-of-line robotic palletizing solutions.

Contact Spiroflow:

Spiroflow Limited

Lincoln Way, Clitheroe, Lancashire

BB7 1QG, United Kingdom

+44 01200 401774

Spiroflow Systems, Inc.

& Spiroflow Automation Solutions, Inc.

1609 Airport Road, Monroe

North Carolina 28110 U.S.A.

+1 704 766 8673