Types of Mechanical Conveyors

There are several types of mechanical conveyors used for bulk material transport, each suited for specific applications and material types:

- Belt Conveyors: Ideal for long-distance transport with minimal energy consumption.

- Chain Conveyors: Suitable for heavy loads and high-temperature environments.

- Screw Conveyors: Effective for moving semi-solid materials, powders, and granules.

- Bucket Elevators: Designed for vertical transport in industries like agriculture etc.

Components for bulk material handling

At STIF, we specialize in providing optimized components for bucket elevators to ensure their efficiency and safety.

- JET – Elevator Buckets: Our buckets are available in various materials and forms, including steel, stainless steel, polyethylene (PE), polyamide (PA), and polyurethane (PU), making them adaptable to a wide range of products such as grains, flour, rice, sand etc.

- BELTJET – Elevator Belts: We offer large range of multi-ply and single ply so-called Very Low Elongation (VLE) elevator belts. These belts ensure enhanced durability and security for installations by minimizing elongation and wear overtime.

- SENSORJET – Safety Devices: Our safety devices help prevent hazardous situations that could lead to ignition sources and explosions. The four primary risks associated with bucket elevators include:

- Belt misalignment

- Under-speed elevator running

- Material choke

- Excessive heat at pulley levels

Our active safety devices detect these risks, ensuring safer operation and mitigating explosion hazards.

Passive Explosion Protection Solutions

STIF also provides passive explosion protection systems designed to evacuate explosions out of bucket elevators. These include:

- Vent Explosion Panels VIGILEX: Designed for outdoor applications, these panels provide controlled explosion venting.

- Flameless Venting Devices VIGIFLAM VQ & VI: These devices are ideal for indoor applications, allowing pressure release without flame propagation.

VIGIFLAM VI – Tailored Protection for Conveyors and Bucket Elevators

Our latest innovation, VIGIFLAM VI is particularly optimized for the protection of industrial enclosures such as

- Bucket elevators

- Belt, chain, and screw conveyors

- Filter units, bins, mills, crushers, and cyclones

These systems are often exposed to explosion risks due to the presence of combustible dust. This system effectively neutralizes the effects of flames, embers, and other burning elements that are released during an explosion discharge, significantly reducing risks to people and infrastructure within industrial buildings.

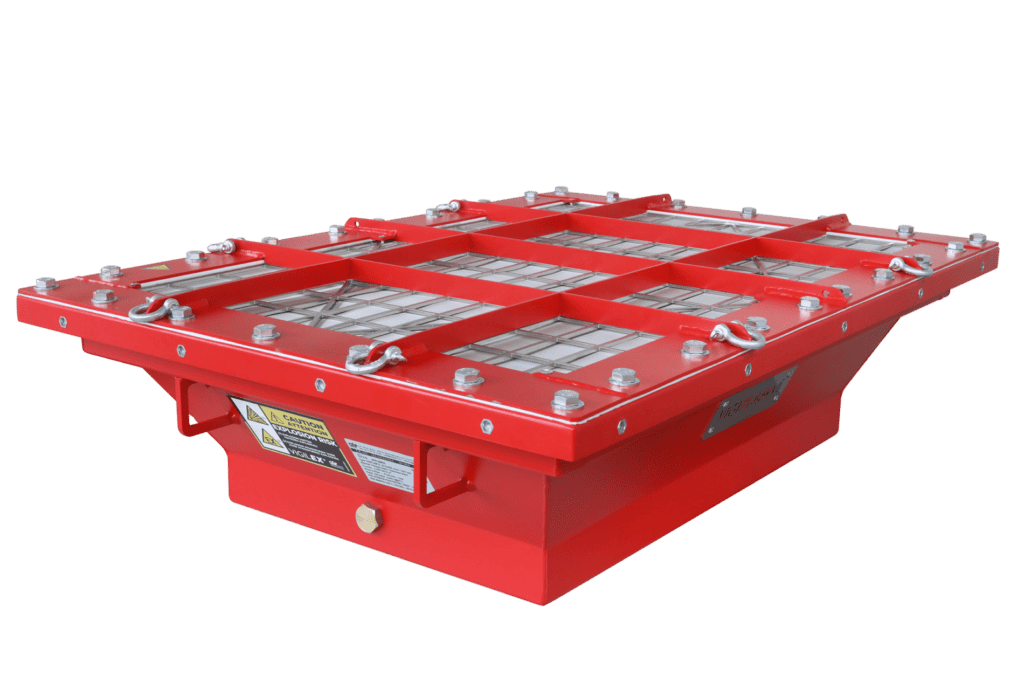

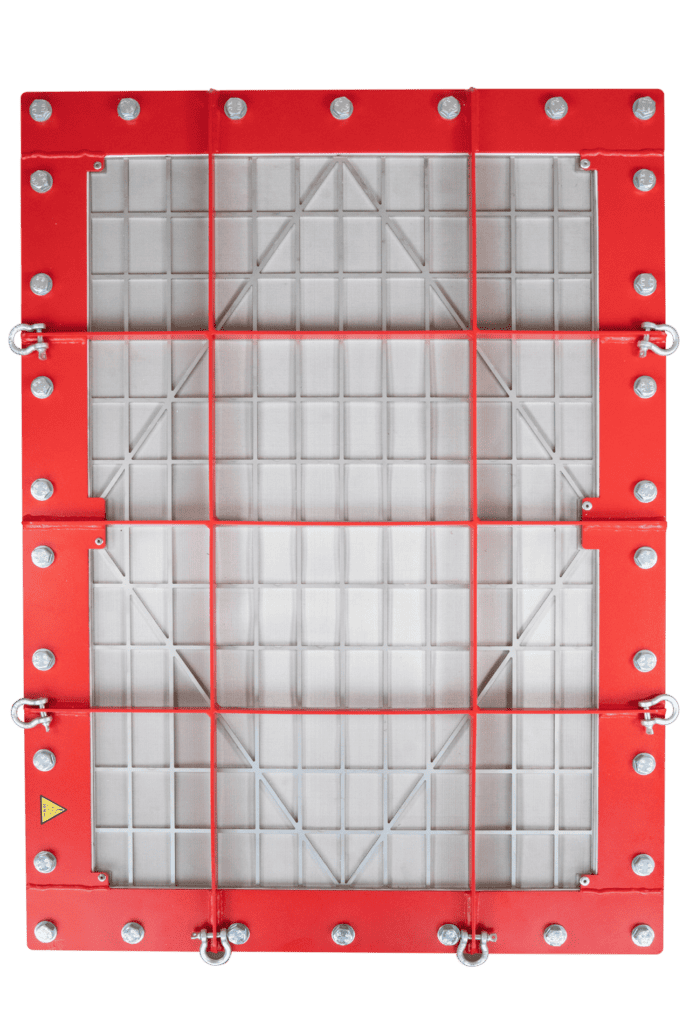

VIGIFLAM VI is a rectangular flameless explosion venting device composed of three key elements:

- A body ensuring reliable attachment to the protected enclosure.

- A multi-layer metal filter designed to cool and contain flames.

- An innovative explosion panel weakened at its center, allowing controlled rupture in case of excessive overpressure. This innovation enables the reduction of the space required for the panel to open and intrinsically the height and weight of VIGIFLAM VI.

VIGIFLAM VI is intended for industries with production sites that need to be protected against dust explosion risks inside buildings, including cereal, wood and pharmaceutical industry.

Conclusion

Mechanical conveying plays a crucial role in the efficient handling of bulk materials. By leveraging STIF’s advanced components and safety solutions, industries can ensure reliable and secure material transport while minimizing risks associated with explosions. Our continued innovation, such as VIGIFLAM VI, reaffirms our commitment to providing cutting-edge solutions for bulk material handling systems.