Risk of Dust Explosion

A mixture of air and dust can be explosive under certain conditions. When flammable material is handled in large quantities, the dust level can become so high that there is a risk of explosion. When flammable dust is mixed with air and the dust concentration becomes sufficiently high, the fire in one particle can ignite the other – and then things go wrong.

Flameless Explosion Venting

Flameless explosion venting enables safe explosion relief in enclosed or indoor areas without the release of flames, sparks, and heat to the surroundings. The system can thus be used for machines and equipment located in areas that are difficult to access, without the need for conversion or adaptation of building parts, which typically must be carried out when using classic types of explosion relief.

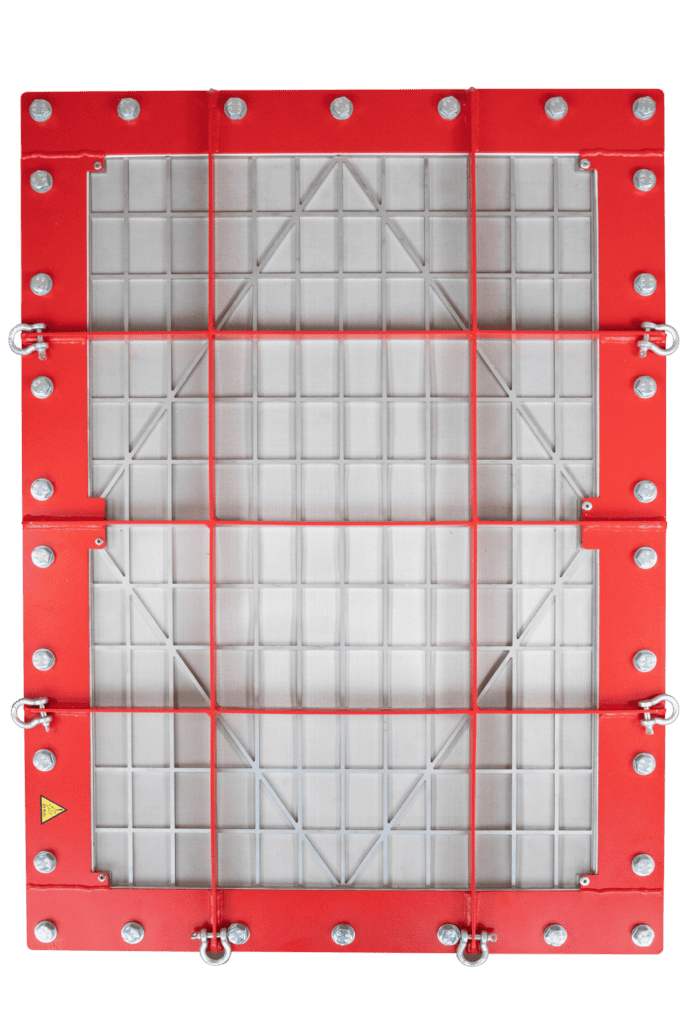

VIGIFLAM VI – Optimized Design for Enhanced Safety

VIGIFLAM VI is a rectangular flameless explosion venting device composed of three key elements:

- A body ensuring reliable attachment to the protected enclosure.

- A multi-layer metal filter designed to cool and contain flames.

- An innovative explosion panel weakened at its center, allowing controlled rupture in case of excessive overpressure. This innovation enables the reduction of the space required for the panel to open and intrinsically the height and weight of VIGIFLAM VI.

This system effectively neutralizes the effects of flames, embers, and other burning elements that are released during an explosion discharge, significantly reducing risks to people and infrastructure within industrial buildings.

Tailored Protection for Conveyors and Bucket Elevators

Thanks to its compact and high-performance design, VIGIFLAM VI is particularly optimized for the protection of industrial enclosures such as:

- Bucket elevators

- Belt, chain, and screw conveyors

- Filter units, bins, mills, crushers, and cyclones

These systems are often exposed to explosion risks due to the presence of combustible dust. Installing VIGIFLAM VI significantly minimizes potential damage by preventing flame propagation and protecting infrastructure and personnel.

VIGIFLAM VI is intended for industries with production sites that need to be protected against dust explosion risks inside buildings, including cereal, wood and pharmaceutical industry.

Technical Features

- Certified for organic and fiber dust

- KST max: ≤ 200 bar.m/s

- Pmax: 9.4 bar

- Pred: 1 bar

- Pstat: ≤ 0.1 bar (±20%)

Key Advantages of VIGIFLAM VI

- Compact Design: Optimized to fit seamlessly into industrial environments.

- Optimized Weight: Ensuring easy installation and maintenance.

- Competitive Price: A cost-effective solution without compromising on safety.

- Production on 3 Continents: Ensuring global availability and rapid delivery.

A Must-Have Industrial Safety Solution

By integrating VIGIFLAM VI into their facilities, industries benefit from a reliable and high-performance device that meets safety requirements EN 16009. Its effectiveness, easy installation, and adaptability to industrial environments make it a strategic choice for preventing explosion risks and securing production sites.

To learn more about VIGIFLAM VI and discover how it can enhance the safety of your equipment, contact our team of experts today.