Bulk bags (also known as Big Bags and Super Sacks) are 2,000 to 4,000 pound large sacks used to transport and store dry materials. The bags have an outlet spout which is untied to release the material. Simply untying the spout to release the material can be dusty, hazardous and create a mess. The Carolina Conveying bulk bag station with outlet spout clamp is critical for applications where minimal operator dust exposure is required, and/or sanitary applications where product cannot contact the outer bag which is often dirty or soiled during transport.

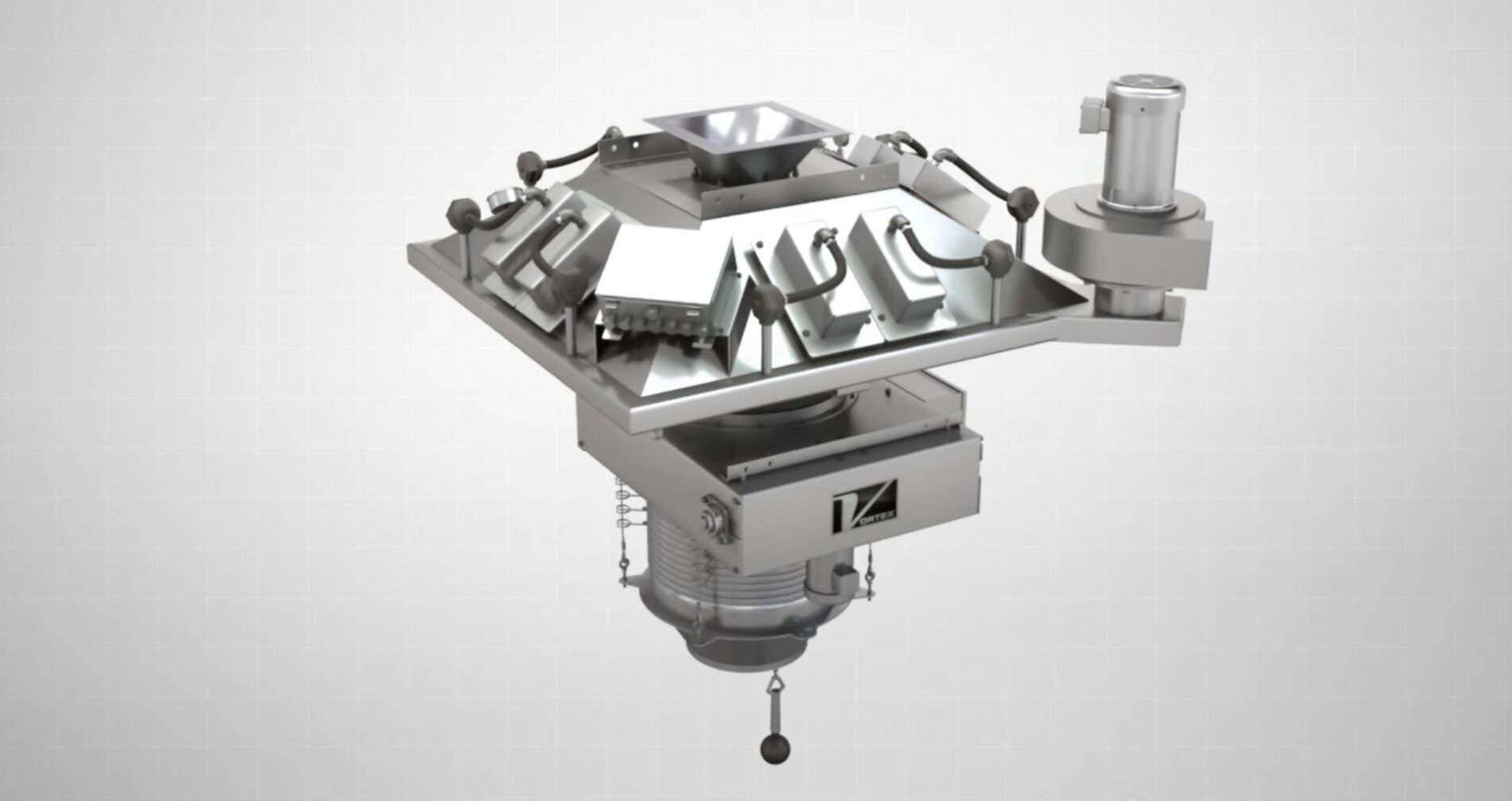

The outlet spout clamp consists of a feed tube and pneumatically operated clamp ring. The feed tube and clamp are enclosed in a large access module with an access door safety interlock which disables all pneumatics when the door is open.

With the door open, the bulk bag outlet spout is pulled down through the clamp ring and then over the OD of the feed tube. If the bag has a liner, it is either stuffed down inside the feed tube or pulled over the OD of the feed tube. With the bag spout in place and the door shut, the pneumatic clamp ring is lowered down tight against the top of the feed tube. A food grade gasket on the underside of the clamp insures a dust-tight seal between the bag and steel tube.

Product is now discharged from the bulk bag with a dust-tight seal. The product also cannot contact the outside of the bag. The feed tube and clamp ring are totally enclosed in our access module ensuring that any accidental spills are contained. A vent on the back of the access module connects to a central dust collection system, pulling negative air for any airborne dust while removing the empty bag.

Optional Pneumatic Pinch Bars clamp down on the bag outlet spout to stop flow at any time. The bag then can be retied shut and removed with material still in the bag.

An optional bag deflator is also available that pulls out all dust-laden air from the bag once it is empty, deflating the bag at the same time for easier disposal.

If minimizing dust and product contamination is critical to your process, the Carolina Conveying Bulk Bag Station is the most dust free and sanitary way means of discharging material from bulk bags. To see the feed tube and clamp in operation, please check out the video “Clamping Down on Dust”.