Employers are legally required to identify all hazards and put in place controls to reduce safety risks for their staff. This obligation can have big implications in manufacturing where there are many potential physical dangers in the workplace.

Bulk Powder Processing is High Risk

Bulk powder processing involves handling large quantities of powders like chemicals, food ingredients, and pharmaceuticals, presenting risks to factory staff in many ways, including:

- Dust inhalation: Powders generate dust, which can cause respiratory problems. Exposure to some powders can lead to respiratory diseases like silicosis, asthma, and lung cancer.

- Fire and explosion hazards: Flammable powders can ignite or explode when exposed to sparks caused by machinery or static electricity resulting in serious injuries or fatalities.

- Physical injury: Workers risk physical injury from trips and falls, getting hands caught in moving machinery parts, and accidents during daily maintenance activities like changing flexible connectors using screwdrivers.

While providing personal protective equipment and training on safe powder handling practices are crucial steps in mitigating these risks, investing in high-quality process equipment with advanced safety features will provide far-reaching risk reductions for staff.

Flexible Connections Are Potential Danger Points

Common locations for dust leakage and potential hand-injuries in bulk powder processing are the flexible connectors at transition points between pieces of equipment.

Having flexible connectors that contain powder effectively and don’t leak, even when moving, is essential. They also need to be easy to fit without risk to operators’ hands when installing or removing them.

Old-Style Hose Clamps Can Be Particularly High Risk

Hose clamps, a common fastening method, usually involve using screwdrivers in potentially dangerous positions, and injuries to hands and fingers when they slip can be nasty.

Hose clamps are also notorious for leaking and not being dust-tight, especially when operating under pressure or with movement, like on sifters.

Flexible connectors give access to the product flow inside the production line, which is also a significant risk if you have machinery like rotary valves or rotating knives operating nearby.

Workers’ hands can be put in danger when removing connectors for any reason close to these types of equipment, and precautions must be taken to follow proper protocols.

What Is The Worker-Safe Alternative to Hose Clamps?

The BFM® fitting snap-fit connector system is now setting the standard for cleaner, safer powder processing.

BFM® fitting’s Seeflex connectors and spigots (adaptors) are designed to create a 100% sealed transition so no dust can escape into the factory environment, keeping the air and surfaces cleaner, and significantly reducing the risk of secondary explosions.

The Seeflex materials also have static-dissipative properties to help eliminate the build-up of electrostatic charges in high-risk areas.

If an explosion does occur inside the process equipment for any reason, BFM®‘s strong and durable fittings are pressure-resistant, and designed to contain the explosion so it can be vented out through the proper explosion relief systems.

What about the risk to operators’ hands? The standard BFM® fitting connector range’s easy snap-fit means there is no need for difficult-to-access screws.

Controlling Staff Access To More Dangerous Transitions

If you have rotary knives or valves close to flexible connector access points, the Tool Release (TR) options for the BFM® fitting system should be used.

The BFM® TR connectors have a much firmer snap band, making them virtually impossible to remove by hand. A specially shaped tool is inserted through a hole in the spigot to release and remove the connector. Only a designated holder of the TR tool can remove the connector as a safety control.

The standard TR system is a round-shaped tool and a hole is simply drilled in the spigot.

If you have concerns that staff may improvise a tool themselves to poke through the TR hole, our ‘Smiley Face’ TR Tool option is the next safety option.

The spigot wall has a unique shaped hole punched into the top ridge, which only fits the specific crescent shaped Smiley Face tool – an added level of security control.

Know When Your Connectors Are Removed

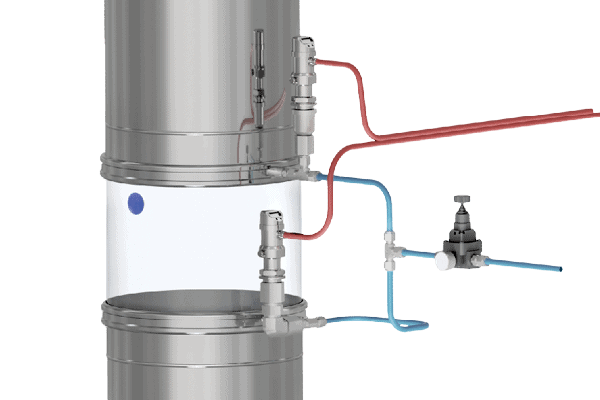

For the ultimate peace of mind, you can monitor when a BFM® fitting is removed in potentially dangerous areas with the Pneumatic Monitoring System.

This system works by pumping pressurised air between the cuff of the BFM® connector and the spigot. Air line sensors immediately detect if this outward pressure is released as the connector cuff gets pushed inwards anywhere around the connector when it is being removed, setting off an alarm and/or shutting off any moving parts below.

The system has a tamper-proof gauge that can be used as a positional sensor to ensure all connectors are installed correctly. There are two options available– an IP65 rated or an ATEX Category 3 rated.