In fact, sensor and IoT markets are projected to grow at 9.6 percent CAGR through 2029 reaching $22.6 billion, according to Meticulous Research Report.

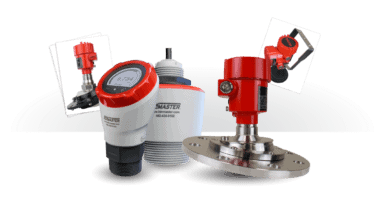

BinMaster is responding to Industry 4.0 demands with level sensors and software. These tools advance business priorities like production efficiency, error reduction, and product consistency.

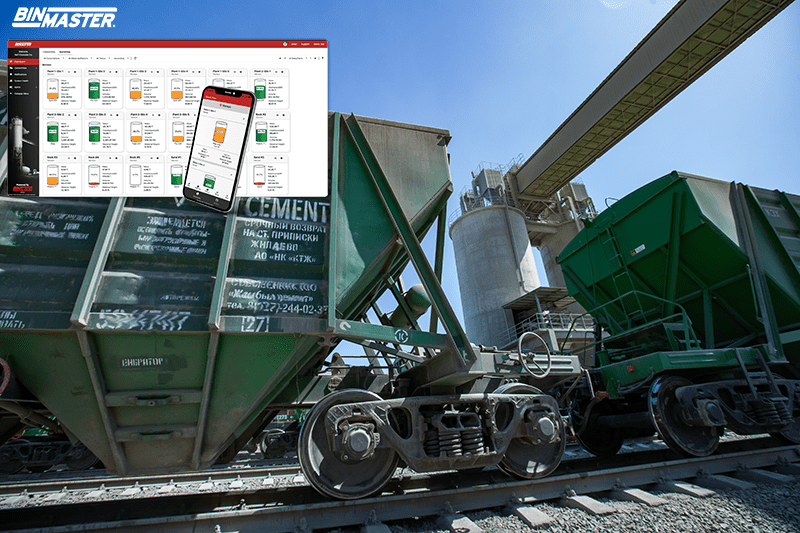

Case study: Storing bulk materials for cement and clinker

A2Z Concrete Company* produces and trades cement and clinker to the tune of 10-million-ton cement production capacity per year. A2Z’s production centers around a major urban center requiring 25,000 tons per day.

A2Z moves cement bulk ingredients from silo to silo. Train capacity is 7,000 tons and another 6,000 tons per day for trucks. Stock silos are monitored daily as BinMaster NCR-80 radar sensors measure levels and then send the data to BinCloud® IoT-based software.

A2Z works with a low value per weight product, so logistics cost is a considerable financial component. Cement production differs from factory-produced products which rely on just-in-time systems.

A2Z looks to avoid stock-out risks. Forecasting ensures availability in the bulk market. This cement operation considers safety stock a priority. Production is divided into raw material preparation, mix production, fuel preparation, clinker, and cement production. Finally, cement preparation supplies customer demand.

Thanks to accurate measurement A2Z Cement Company realized savings, and therefore profit, by forecasting based on level measurement history to determine optimal times to order to leverage truck and rail transportation. Measured decisions helped the company avoid a 15 percent stock out unit loss of profit.

*A2Z anonymized to ensure data cannot be linked to any individual company in any manner.

Demand forecasting improves profits

How often should one replenish bulk powders, pellets, powders, and other solids? Those who are more reactive (order when low on material) versus proactive (project the need for three truckloads in 44 days), may be losing money.

No matter the industry, demand forecasting uses predictions based on history to estimate future demand. These predictions open possibilities to employ economies of scale. They help plan maintenance and labor scheduling. Demand forecasting will never produce 100 percent perfect accuracy, but forecasting can increase efficiency, anticipate production, and provide a better customer result.

According to a study by the International Journal of Production Economics, businesses that use demand forecasting to purchase bulk materials can see a reduction in inventory costs of up to 20 percent. This is because demand forecasting allows businesses to anticipate customer needs and avoid overstocking or running out of material, which can be costly.

Demand forecasting also helps businesses to plan for economies of scale. By anticipating customer needs, businesses can purchase materials in bulk, which can lead to significant savings on raw materials and transportation costs. A study by the Journal of Purchasing and Supply Management found that businesses that use demand forecasting to purchase bulk materials can see a reduction in costs of up to 30%.

Smart and reasoned decisions on ordering directly impact profit margins, cash flow, resource allocation, staffing, and even expansion plans.

Software platforms build historical data

Understanding the positive impacts resulting from high-tech level sensors, BinMaster builds bulk inventory software named BinCloud®, which receives level data from sensors and makes it available on a cloud-based platform.

Material inventory history helps form a use pattern to optimize storage. Material inventory control of plants can be used to optimize storage cost and ordering for optimal ordering and storage.

Utilizing BinMaster bulk inventory technology increases accuracy, reporting, ordering, and employee safety. BinCloud® software unleashes people from cubicles and prompts collaboration on an IoT platform. The process is safer. Machines labor, while people analyze data.