The Challenge of Manual Operations

Many industries still rely on manual operations for handling heavy materials, such as carrying and emptying 50 lb bags into reactors, mixers, day bins, and hoppers. Workers must physically carry these heavy bags, slit them open, and empty their contents, which exposes them to significant physical strain and potential hazards from dust and other contaminants. These tasks are not only laborious but also pose health risks and operational inefficiencies.

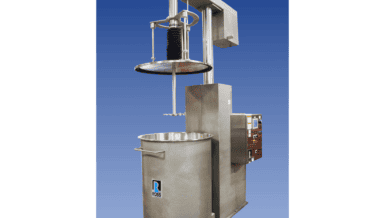

Luxme International Ltd.’s Innovative and Patented Solution

Addressing these challenges, Luxme International Ltd., with its 45 years of expertise in slitting and conveying technology, has developed an affordable, low-cost powder bag opening and conveying package designed to automate the labor-intensive processes involved in material handling. This package incorporates several key functionalities that streamline operations, enhance safety, increases efficiency and boosts profits.

Key Features of the Low-Cost Automation Machine

- Feeding Conveyor

The process starts with a feeding conveyor where the operator manually places the 50 lb bag filled with the product. This simple step initiates the automation sequence. - Automatic Slitting – Patented Design

The machine is equipped with an advanced slitting mechanism that automatically adjusts the blades to slit the bag on three sides, accommodating different bag sizes. This ensures precise and consistent slitting without manual intervention. - Inversion and Emptying

Once slit, the bag is inverted, and its contents are emptied efficiently. This process minimizes product wastage and ensures thorough emptying of the bag. - Air Blast Cleaning

Empty bags are subjected to an air blast cleaning process to remove any residual product. This step is crucial for maintaining cleanliness and reducing contamination risks. - Scalping Paper Pieces

To ensure product purity, the machine scalps paper pieces from the product. This feature prevents any foreign materials from mixing with the product, maintaining its quality. - Empty Bag Compaction

The empty bags are compacted to reduce waste volume. This compaction process not only saves space but also facilitates easier disposal or recycling of the bags. - Dust Filtration and Recycling

An air-born dust filter captures dust generated during the process. The collected dust is then recycled back to the slitter, ensuring minimal product loss and maintaining a cleaner working environment. - Tubular Chain Conveyor

Finally, the product is conveyed to its destination using a tubular chain conveyor. This ensures smooth and efficient transportation of the product with minimal handling.

Operational Efficiency

The machine is designed for high throughput, capable of processing 4 to 5 bags per minute. It handles 50 lb bags containing free-flowing, non-compacted products packed in multi-wall, kraft paper bags with or without PE inner liners. This high efficiency significantly reduces the time and labor required for material handling.

Enhancing Workplace Safety

One of the most significant advantages of this low-cost automation machine is its ability to improve workplace safety. By automating the handling and emptying of heavy bags, operators are not exposed to the physical strain of lifting and emptying bags. Additionally, the automated processes reduce exposure to dust and other contaminants, creating a safer and healthier working environment.

Conclusion

Luxme International Ltd.’s low-cost automation for opening bags and feeding powders downstream exemplifies the potential of affordable automation solutions in transforming industrial operations. By automating the handling of heavy bags, industries can achieve higher productivity, reduce manual labor, and enhance worker safety. As businesses navigate the post-COVID era and address economic challenges, adopting low-cost automation technologies will be essential for maintaining competitiveness, operational efficiency, and profitability.

Embrace the future of automation with Luxme International Ltd.’s innovative, patented solutions, and take a significant step towards safer, more efficient, and cost-effective industrial operations.