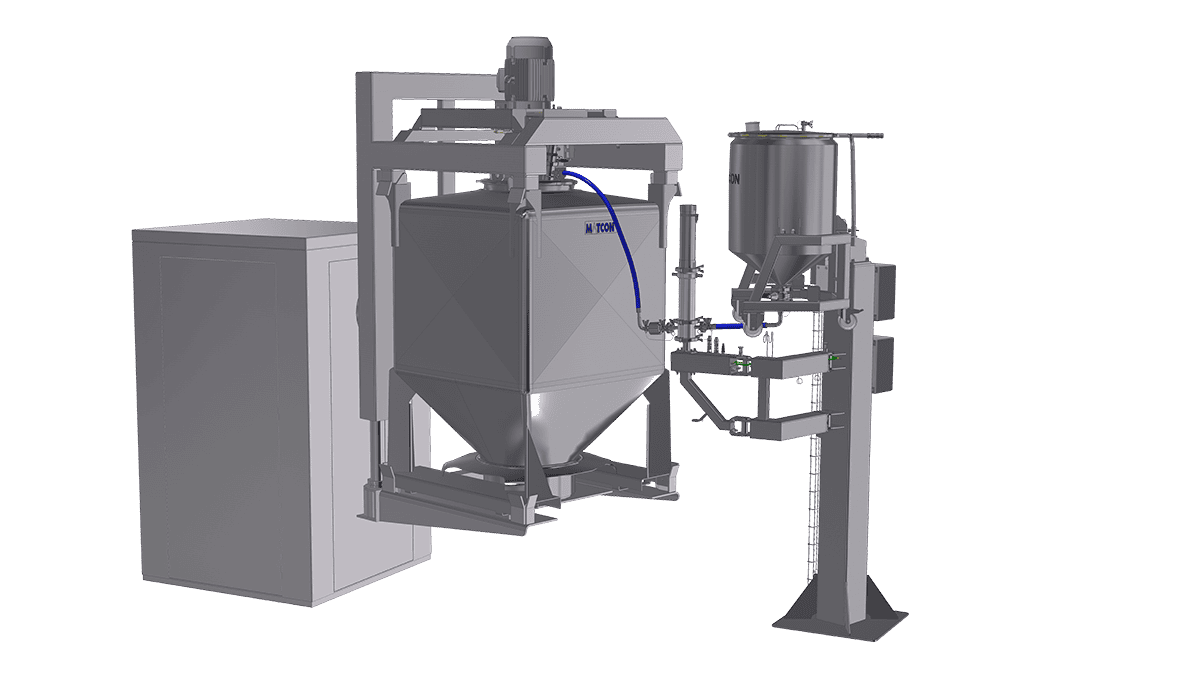

One groundbreaking innovation that can help to transform the industry is the Liquid Addition System for IBC (Intermediate Bulk Container) Tumble Blending, developed by Matcon. This article explores how this system works and the numerous advantages it offers to the process of food manufacturing.

Understanding the Liquid Addition System

The Liquid Addition Blending System is a patented, cutting-edge solution designed to address the challenges associated with integrating liquids into powder blends. Traditionally, adding liquids to powder mixes required the use of Fixed Mixers, which often led to lengthy downtimes due to the cumbersome cleaning processes required between recipe changeovers. However, the advent of the Matcon Liquid Addition System has revolutionised this process, enabling the use of container-based blending and all the associated benefits of fast changeovers of IBCs between batches, reducing downtime & maximising production uptime.

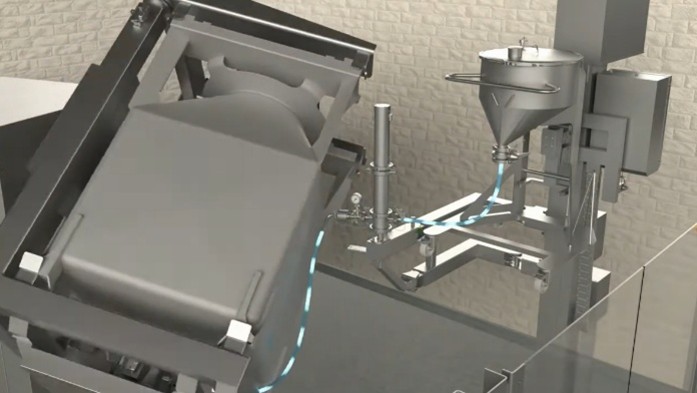

At the core of the system is the innovative method of automatically injecting controlled ‘shots’ of liquid into the powder mix. This occurs within the confines of the IBC during its blending cycle, eliminating the need for manual intervention or the opening of the blending vessel. Used in conjunction with a high-shear intensifier in the outlet of the IBC, the liquid is dispensed at the blade tip of the Intensifier, which then rapidly and evenly disperses the liquid throughout the mix, thus preventing the formation of lumps or agglomerates.

Key Components and Functionality

The system comprises several sophisticated components, each playing a vital role in ensuring seamless operation:

1. Automated Injection Mechanism: Liquids are injected into the powder mix during each rotation of the IBC. This automation eliminates the need to halt the blending cycle, thereby enhancing efficiency and reducing production times.

2. High-Shear Mixing: The incorporation of a high-shear intensifier inside the IBC ensures that the liquid is fully integrated into the powder, resulting in a homogeneous blend without any agglomerates.

3. Liquid Volume control: The injection nozzle within the IBC lid, combined with the control system allows the injection aperture to be adjusted to give flexibility and control of the of the ‘shot’ size to suit the viscosity or volume of liquid required per batch.

4. Weight Monitoring & PLC control: These components work in tandem to deliver a seamless and automated transition between the 3 key blending stages of ‘dry’, ‘liquid addition’ and ‘wet’ blending. The liquid tank weight is monitored to identify when the liquid is fully utilised. This ensures homogeneity is optimised at each stage.

5. Size options: The Liquid Addition system is available in two sizes, the Low Volume model supports 1-10 litres and the High Volume covers 5-150 litres of liquid additions, catering to a wide range of manufacturing needs.

6. CIP Flushing System: To minimise downtime associated with cleaning, the system includes a Clean-In-Place (CIP) flushing capability. This enables the keeping the blender in production with minimal interruptions.

Advantages for Food Manufacturers

The Liquid Addition System offers a plethora of benefits that are particularly advantageous to food manufacturers and contract manufacturers of food products:

1. Enhanced Flexibility and Efficiency

One of the most significant advantages is the system’s flexibility. It allows manufacturers to switch between recipes rapidly, without the need for extensive cleaning, thereby reducing downtime. This is particularly beneficial in industries where product variety and quick turnaround times are critical.

2. Improved Product Quality

The controlled and precise integration of liquids ensures a consistent and high-quality end product. The prevention of lump formation and the homogeneity of the blend result in superior texture and flavour, meeting the high standards expected in the food industry.

3. Reduced Manual Handling and Contamination Risk

The automation of the liquid addition process significantly reduces the need for manual handling, thereby minimising the risk of contamination. This is especially important in food manufacturing, where hygiene and safety are paramount.

4. Cost-Effective and Sustainable

By optimising resource use and reducing waste, the Liquid Addition System contributes to cost savings and enhances sustainability. The ability to clean parts offline without halting production further boosts operational efficiency, translating into economic benefits for manufacturers.

5. Scalability and Versatility

The system’s compatibility with both low and high-volume liquid additions makes it suitable for a wide range of applications, from small-scale pilot projects to large-scale production. This scalability ensures that manufacturers can adapt the system to their specific needs, whether they are producing small batches of artisanal products or large runs of mainstream items.

The future expansion of Tumble Blending capabilities

The Liquid Addition System in IBC Tumble Blending represents a significant leap forward in the realm of food manufacturing. This innovation offers a host of advantages, including enhanced efficiency, improved product quality, and reduced operational costs. By embracing this technology, manufacturers can not only meet current consumer demands but also position themselves at the forefront of an industry that is constantly evolving.

As the food manufacturing landscape continues to change, innovations like the Liquid Addition System will play a crucial role in shaping the future. For those looking to optimise their production processes and deliver high-quality products consistently, this technology provides a powerful tool to achieve these goals. Embrace the future of blending and discover how this revolutionary system can transform your operations and drive success in an increasingly competitive market.

For questions or more information please contact Matcon Head Office, Evesham (+44) 1386 769 000 or go to https://www.matconibc.com/contact-us