One customer, processing organic cane sugar, faced severe production delays due to heavily agglomerated bulk bags. The material had hardened during transport, making manual break-up methods slow, inconsistent, and labor-intensive. They needed a fast, reliable solution to restore material flow and get operations back on track.

A Rapid Solution:

The Material Master® Bulk Bag Conditioner QuickShip Unit delivered fast, effective results for this customer who was processing up to 30 bulk bags of organic cane sugar daily. Built to eliminate flow issues from hardened material, it featured a hydraulic lift, powered turntable, and twin hydraulic conditioning arms for efficient, consistent material breakup.

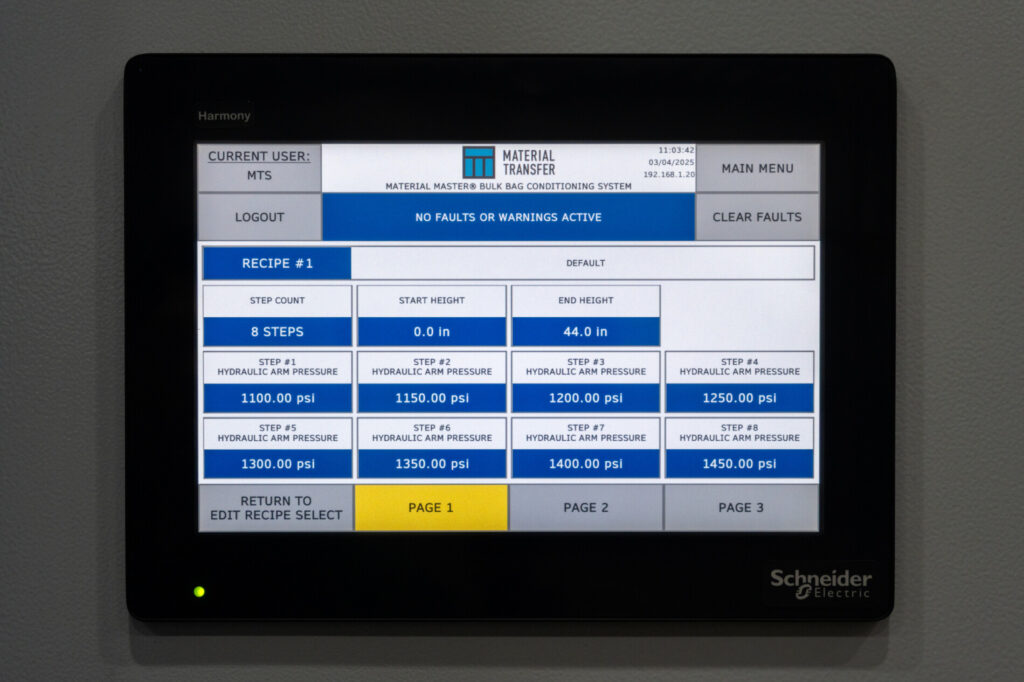

Rated Class II, Division 2 for combustible dust environments, the system included safety guards, a light curtain, and an Allen Bradley PLC with 10” touchscreen HMI. With bag top conditioning, a pressure-relieved maintenance mode, and a VFD for 30% faster cycles, it offered powerful, compliant performance, finished in high-visibility Safety Blue.

The Fast-Track to Productivity: Unit Features & Benefits:

Maximize Floor Space Without Compromise | The QuickShip Unit features the smallest footprint on the market, making it ideal for space-constrained facilities. Its compact design helps customers maximize valuable floor space without sacrificing performance, freeing up room for other critical operations and improving overall plant efficiency.

Get Repeatable Results & Consistent Material Flow | The Material Master® “Recipes” function, built into the HMI, allows operators to save and recall pre-set conditioning parameters tailored to specific materials. This ensures repeatable results, consistent material flow, and faster setup times, helping streamline operations and improve overall production efficiency, batch after batch.

Condition with Confidence, Every Time | With 75,000 pounds of hydraulic force, the heavy-duty conditioning arms break down even the toughest, agglomerated materials, fast. Their pivoting design prevents binding and ensures reliable, high-force performance, giving the customer consistent flow, reduced downtime, and improved throughput.

The Material Master® Bulk Bag Conditioner Features & Benefits:

- Class II, Division 2 certification gives the customer confidence that the system meets strict safety standards, helping reduce fire & explosion risks while maintaining compliance with industry regulations.

- Designed with operator safety in mind, the unit includes a load-side safety light curtain and metal guard panels on three sides to ensure secure, compliant operation throughout each cycle.

- The hydraulic lift platform offers 4,000 lbs. of lifting capacity and 48” of vertical travel, giving customers the ability to easily position and condition bulk bags of varying sizes.