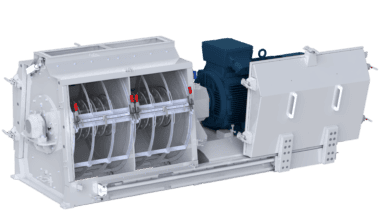

From dumping stations on the plant’s second floor, ginger root, cassia bark and cola nuts are gravity discharged into a Munson Rotary Knife Cutter at the hourly rate of 6000 pounds—or 2700 kilograms—with uniform particle sizes determined by the aperture size of the unit’s 270 degree bedscreen.

The tough, hard roots, beans and nuts place high demands on cutting blades but Munson’s efficient blade replacement minimizes downtime, requiring only four hours versus 1-1/2 days with a previous knife cutter.

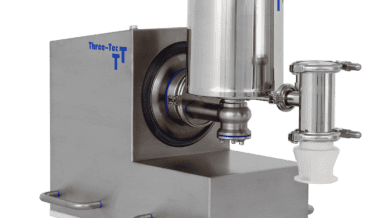

To reduce vanilla beans at an hourly rate of 3000 pounds—or 1360 kilograms—the plant utilizes a Munson Screen Classifying Cutter.

Its helical rotor assembly contains dozens of staggered, parallelogram-shaped cutters, each holding two tungsten carbide cutter inserts, which cut the beans against two stationary bed knives in a continuous spiral cutting and feeding manner, with uniform particle sizes determined by the aperture size of the unit’s 270 degree bedscreen.