Automating Material Handling Maximizes Process Efficiency

VAC-U-MAX pneumatic conveying systems eliminate the need for manual handling, stair climbing, and messy dumping, helping to reduce labor costs, minimize waste, and ensure consistent material flow. Engineered for efficiency, VAC-U-MAX vacuum receiver designs enhance workplace safety, reduce downtime, and integrate seamlessly into existing manufacturing processes. Experience improved productivity and a safer, cleaner work environment with VAC-U-MAX.

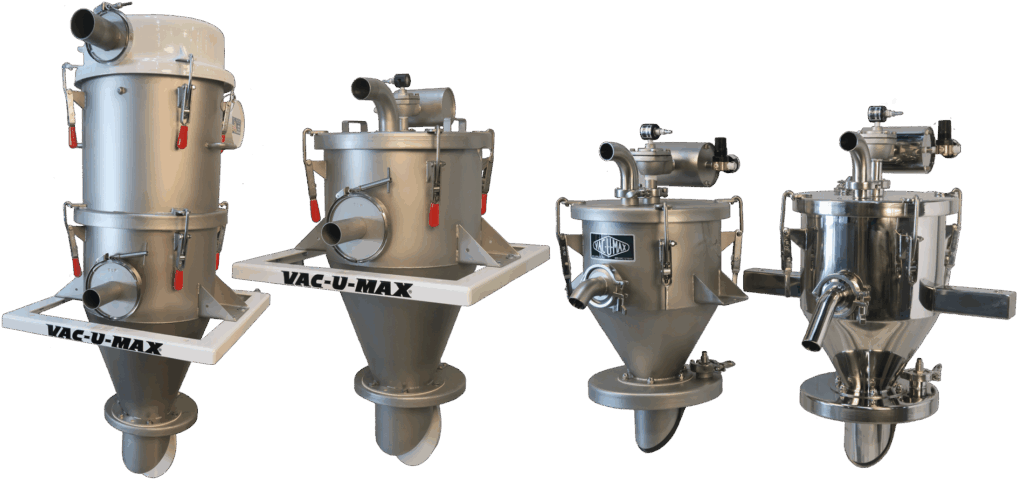

Optimize Material Handling with VAC-U-MAX Custom & Pre-Engineered Vacuum Conveying Systems

- Custom Systems: Tailored for application-specific requirements, capable of handling up to 25,000 lbs/hr (11,300 kg/hr)

- Pre-Engineered Systems:

- Signature Series™: Ready-to-implement solutions designed for efficiency and versatility.

- 1500 Series™: Ideal for vacuum conveying from handfuls up to 1500 lbs/hr (680 kg/hr).

- 3500 Series™: Engineered for higher capacities, handling up to 3500 lbs/hr (1600 kg/hr).

Signature Series: A Comprehensive 5-Part Package

Each VAC-U-MAX Signature Series includes:

- Signature Series™ Vacuum Receiver with automatic pulse filter cleaning

- A vacuum producer

- Pick-up wand

- Convey tubing

- UL-listed control panel

Specialized Solutions for Unique Conveying Challenges

VAC-U-MAX Signature Series are designed for general-purpose vacuum conveying use across industries including food, nutraceuticals, plastics, and chemicals. While they excel in standard applications, VAC-U-MAX also addresses unique challenges, particularly when handling powders and bulk solids that are difficult to convey.

The Tube Hopper Vacuum Receiver

For demanding applications, the Tube Hopper Vacuum Receiver offers an innovative solution tailored for non-free-flowing materials. Key features include:

- Straight-Sided Design: Eliminates edges and ledges, ensuring smooth material flow.

- Rapid Discharge Rates: Reduces non-conveying time, boosting transfer efficiency.

- Automatic Discharge Valve: Precisely matched to the tube’s diameter, enabling quick and efficient discharge of even the most challenging materials.

- Material Flexibility: Available in stainless steel or carbon steel, with standard or sanitary construction to suit specific industry needs.

- Short Discharge Cycles: Virtually continuous conveying accelerates loading and batch transfer processes, enhancing overall system productivity.

VAC-U-MAX’s Tube Hopper material receivers deliver reliable performance, improving efficiency and handling the most demanding material transfer tasks with ease.

Automation That Drives Results

By automating material transfer, VAC-U-MAX accelerates the refill step of processing, maintaining consistent quality, and achieve greater operational efficiency. Put VAC-U-MAX to the test! Visit www.vac-u-max.com/pneumatic or call (800) VAC-U-MAX to learn more!