However, spice processing presents multiple challenges, particularly in achieving consistent particle size without compromising the essential oils and aroma that define spice quality. Traditional grinding methods often lead to excessive heat generation, resulting in loss of volatile compounds, reduced shelf life, and altered taste profiles.

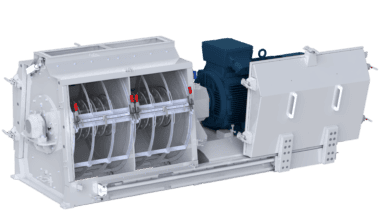

To address these industry challenges, DP Pulveriser Industries introduces the DP® CONTRA Pin Mill—a state-of-the-art solution for efficient, precision spice grinding.The DP® CONTRA Pin Mill is an innovative spice grinding machine designed to process a diverse range of spices, including greasy and sticky varieties that conventional grinding systems struggle with. Its unique design features two driven pin discs rotating in opposite directions, ensuring efficient size reduction. This screen-less design prevents blockages and eliminates material retention inside the grinding chamber, which is critical for preserving the volatile oils in spices that evaporate due to high temperatures. The fineness can be adjusted by altering pin disc speeds. The CONTRA Pin Mill’s wide chamber design allows for continuous operation over extended periods, maintaining optimal performance and preventing heat buildup. For enhanced results, the mill can be equipped with a cryogenic screw conveyor that uses liquid nitrogen for grinding at sub zero temperatures. This innovative feature ensures premium-quality spices with high volatile oil retention and significantly higher production rates compared to conventional grinding methods.

At DP Pulveriser Industries, we are committed to providing innovative size reduction solutions tailored to industry-specific needs. Get in touch with us today to explore how the DP® CONTRA Pin Mill can revolutionize your spice grinding operations.