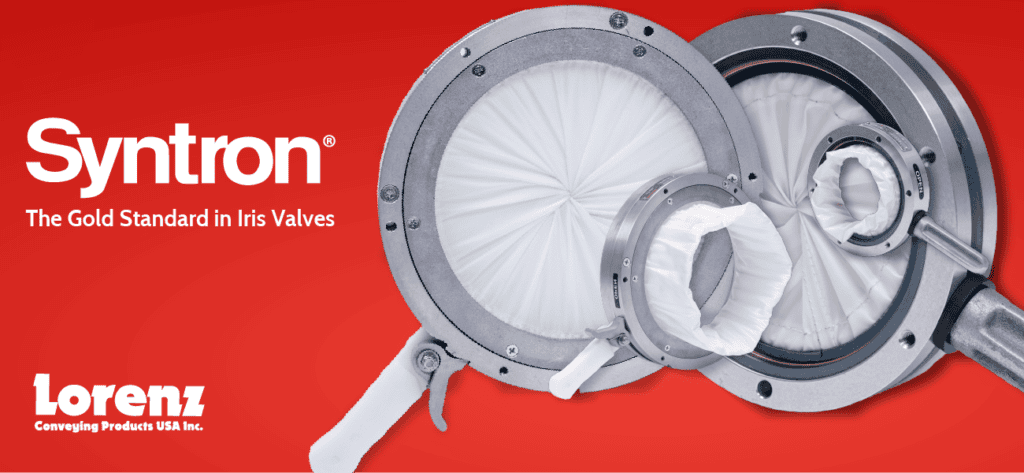

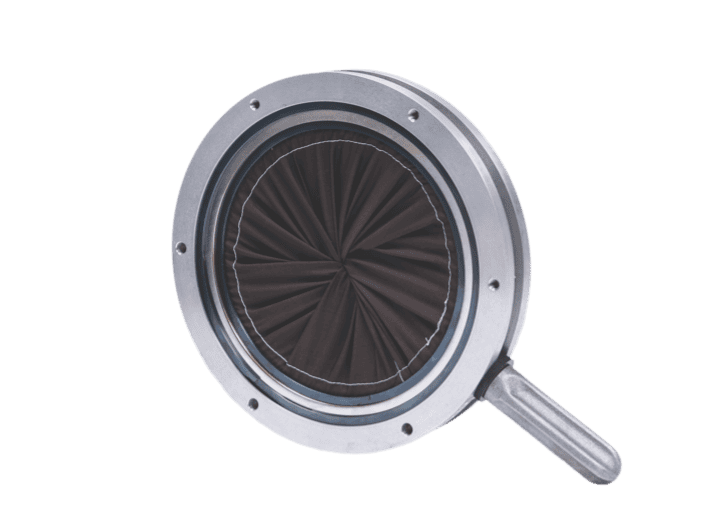

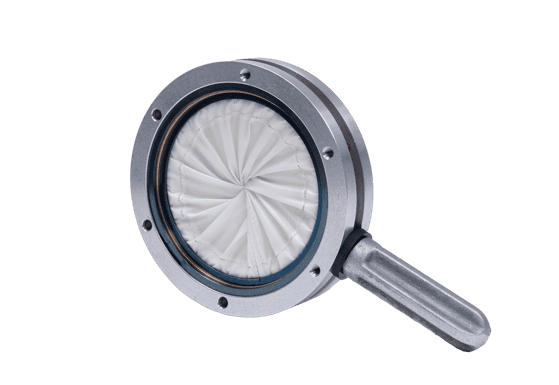

Rotate the handle through a 180-degree arc to fully open/close the valve allowing adjustable material control from full feed to trickle feed.

Standard construction includes: 4 oz. nylon diaphragm allowing maximum temperatures 82°C (180°F). Optional wear sleeves are available for handling abrasive, fine or dusty products. Various diaphragm materials are available to suit your specific application.

Choose Syntron® as an alternative to Butterfly Valves or Slide Gates.

- Alternative to Butterfly Valves & Slide Gates

- Initial low-cost investment

- Low maintenance

- Easy diaphragm replacement

- Minimum mounting area required

- Durable construction for many years of service.

- FV Series – Single diaphragm – twist lock handle

- SFV Series – Single diaphragm – trigger handle

- DFV Series – Double diaphragm – trigger handle