One key feature of the Titan Maintenance Gate is its narrow profile, measuring less than 2 inches (50 millimeters) in overall flange-to-flange height. This slim design allows for easy installation in limited spaces, making it an ideal choice for a variety of applications. Constructed with a carbon steel body and frame, the gate exhibits exceptional durability and resistance to abrasion, wear, and corrosion, both from the materials handled and the surrounding environment.

In contrast to many alternative maintenance gates that rely on soft rubber seals directly exposed to the material flow stream, the Titan Maintenance Gate employs a bonnet seal cartridge that prevents material migration and maintains a positive seal to the atmosphere. Additional features include lifting lugs for effortless installation, visual indicators for blade position feedback, and a protective mild steel bonnet cover for operator safety.

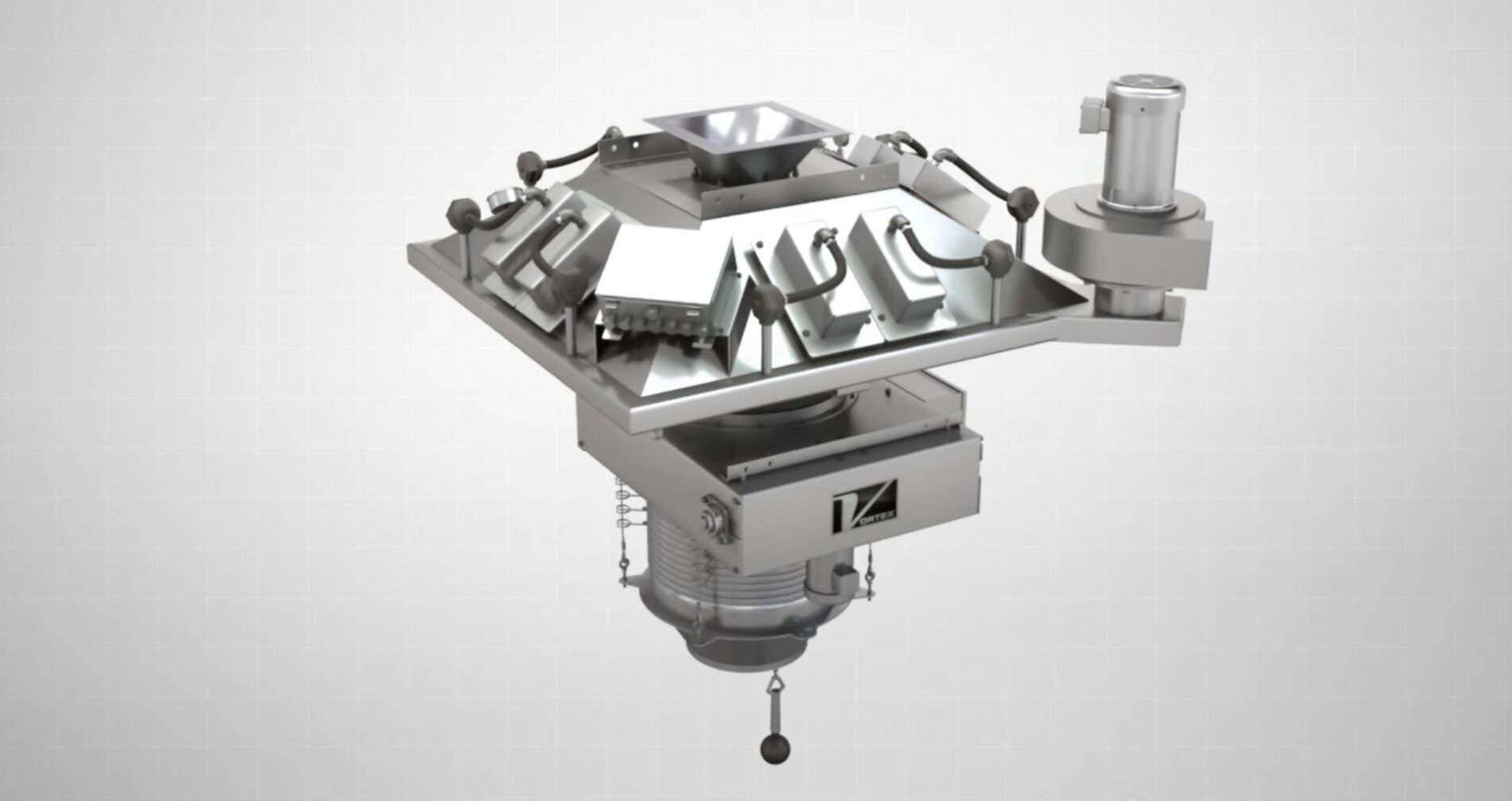

Designed to shut off material flow during maintenance or in the event of an upset condition, the Vortex Titan Maintenance Gate is engineered to close through a standing column of material, making it the ultimate solution for efficient and secure material handling operations.