Best practice choices made during the application phase will lead to a positive outcome for performance, given proper installation, calibration and maintenance.

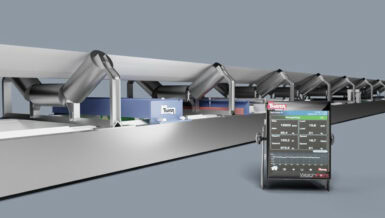

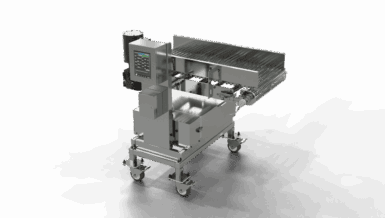

Principle of Operation

A typical belt scale system is composed of a weigh bridge structure supported by load cells, electronic processor, and belt speed sensor. The rate of the material conveyed is computed using the equation Weight x Speed = Rate. Material weight on the belt is measured by load cells, which produce a voltage signal that is sent to the integrator. The integrator also receives input in the form of electronic pulses per revolution from a belt speed sensor connected to a tail or bend pulley. Using these two points of data, the integrator calculates the rate of material transferred along the belt in pounds or tons per hour.

Belt Scale Location

The scale should be located at a sufficient distance from the infeed section, so the material has time to become properly profiled and settled on the belt. This distance will vary depending on the conveyor design, flow rate, and material; however, about 4 to 5 times the belt width is usually acceptable.

Since many conveyors may curve up or down along some point, it is important to locate the scale an appropriate distance away from the tangent points of the curve. For concave curved conveyors, the recommended minimum distance for mounting the scale is 40 feet from the tangent points of the curve. With convex conveyors, the minimum distance is 20 feet on the approach side and 30 feet on the retreat side.

The conveyor should be rigidly supported so there will be no deflection caused by the weight of the material. The structure and components also need to be free of excess vibration.

Access to the belt scale is also an important consideration. It should be installed in a location that is easy to access for routine inspection and calibration. Newer designs also offer built-in calibration weights with options for applying the weights by the user outside of the pull-cord zone.

Belt Tension

A gravity tensioning device should move freely and place consistent tension on the conveyor belt. The amount of weight should conform to accepted conveyor design specifications. Ensure that significant water or debris does not collect on or inside the take up weight, thereby causing excessive tension that can create problems for the conveyor and belt scale. A problem exists if the gravity take up does not move at all and therefore maintenance will be required. The screw tensioning device should be adjusted according to the conveyor manufacturer’s specifications, usually just enough to keep the drive pulley from slipping.

Material weight is transferred through the belt and on to the weigh bridge. Changes in tension throughout the day will have a proportionally negative effect on scale repeatability. It is critical to maintain constant and consistent belt tension.

Conveyor belting

Belt scale systems typically average the weight of the belt over at least one complete revolution during zero calibration. But the calibration can be affected by varying thickness, number of splices and condition of the belt. Large variations along the belt will result in less accuracy and non-repeatability. It’s important to keep in mind that a conveyor belt scale weighs material through a large rubber band. The condition and characteristics of that rubber band will affect performance.

Belt loading

Loading is calculated based on the rate value and belt speed. Generally, a belt loading of 10 pounds per foot or greater is preferred. Below 5 pounds per foot there usually is not enough material load to transfer the weight through the belt and onto the scale. The belt will tend to support the weight of the material and not allow it to be sufficiently registered by the scale. In addition, it requires a lower capacity load cell, but much of that capacity will be taken up by the weight of the belt and idler, only allowing a small margin for actual material weight measurement. An accepted solution is to slow down the belt, if possible, to achieve greater loading.

Belt speed

On high-speed belts, generally over 550 feet per minute, there may be a time-on-scale or retention time limitation. It’s good practice to have over 0.50 seconds of time on scale with a minimum of 0.40 seconds. Possible resolutions include increasing the idler spacing and/or installing a multi-idler scale derated for accuracy.

Conclusion

Conveyor belt scales are designed to continuously calculate bulk material flow rate by measuring belt load and speed. They can be applied in many locations throughout an operation for rate control, production and inventory monitoring. Proper selection is important because with increased accuracy comes greater cost. Belt scales respond to vertical forces, both desired and undesired. Many issues are a result of problems with the conveyor or improper commissioning. Careful evaluation of the application, proper installation, calibration and routine maintenance will yield many hours of continuous and reliable service.