As the client upgrades various plants, hygienic housekeeping and automation are paramount. After spending five months evaluating the capabilities, equipment, design issues and approach, 3Sigma Systems was chosen as their bulk material partner.

Customer Needs:

- Provide a system that will discharge this very difficult product without issues. They currently have many problems at numerous facilities, requiring “manual manipulation” of bags.

- Dust-tight design – contain all spills. This is also a major problem at other facilities.

- Ability to modify the unloader, as required, to meet future changes – bulk bag dimensions, products, added features

- This was tested immediately. As soon as the units delivered the client asked to add our Close-It™ valves and Lump Breakers to three of the seven systems.

- Heavy-duty design to ensure uptime and minimize maintenance.

- Ability to refill LIW feeder quickly and reliably.

Solution:

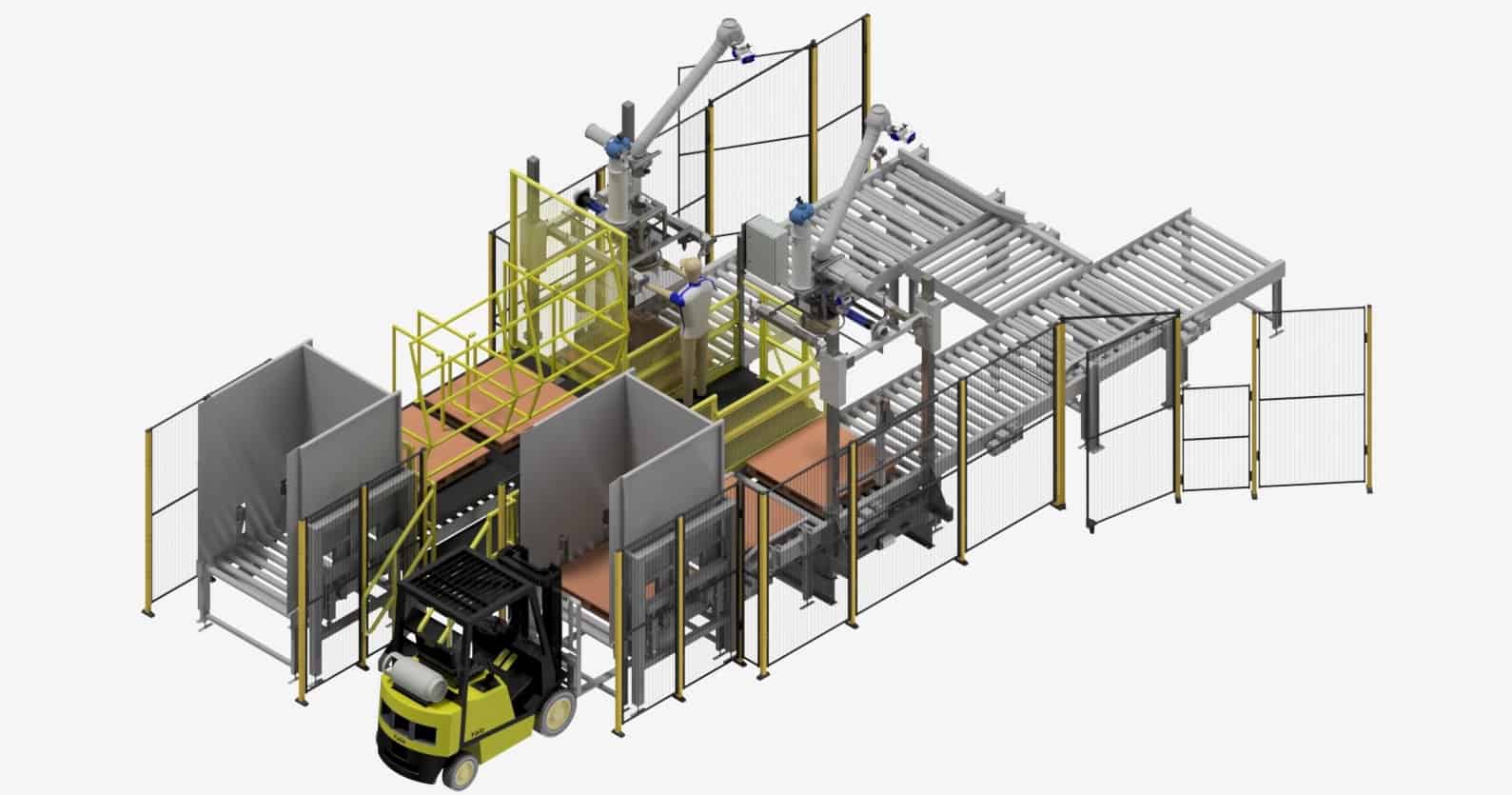

- 3Sigma spent months working on various projects, providing unique solutions, to meet the client’s needs. On this project:

- Provided the Massage-It™ bag massaging system, which consists of a heavy-duty pipe weldment, to properly massage and discharge this product. There is no chance of bending this robust design. In addition, the paddles rotate a full 90-degrees, forcing product into the critical flow path of the bulk bag.

- The oversized Contain-It™ chamber was provided to ensure any and all spills stay contained, not discharging into the plant environment.

The oversized Contain-It™ Chamber contains all product spills. The heavy-duty design is built for years of trouble-free operation.

Our automated dust valve was provided to connect to the dust collection system. This is located on the side of the access chamber. When the door is opened the valve opens, when the door is closed the valve closing, allowing for dust collection to be used only when needed, minimizing the total CFM required.

- The Tube-It™ was designed with an integrated surge hopper, with aeration, to properly stored and discharge product to the LIW feeder below.

- The bulk bag spout is placed inside of the Tube-It™ for a dust tight seal within the access chamber.

- The Close-It™ Valve was provided to allow for bag change outs.

- Self-contained controls were provided which are integrated with the client’s PLC system. When a refill is called for the butterfly valve opens and the Massage-It™ runs until a stop signal is received.

- Electrical and pneumatics are fully plumbed and wired upon shipment. Client provides one 110VAC source, one 80 psig air source and one 460VAC source, for the hoist and trolley.