Plastic processing is converting the plastics’ raw bulk material into (semi-) finished products.

Plastic processing is converting the plastics’ raw bulk material into (semi-) finished products.

Plastics are the most common materials for producing (semi-) finished products, from consumer products to medical devices. Plastics are a versatile category of materials, with thousands of polymer options, each with its specific mechanical properties. Plastic manufacturing processes have been developed to cover many applications and part geometries. For any designer and engineer working in product development, it is critical to be familiar with today’s manufacturing options and the new developments that signal how parts will be made tomorrow. Several complications can arise during the plastic manufacturing process.

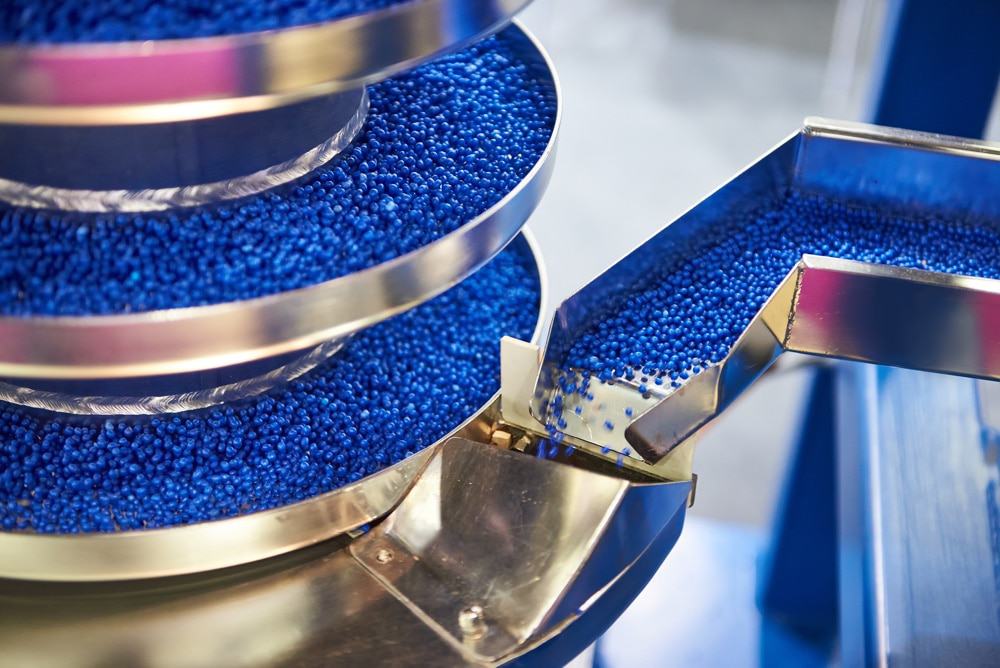

Poor flow can occur when handling the bulk plastic resin, pellets, pastille, and granules. These material flow problems include sticking, blocking, and segregation. Product quality problems can result from material stagnation in storage bins, pellet damage (fines generation), or cross-contamination of batches. Pneumatic conveying of bulk plastics can lead to the formation of angel hair, also referred to as streamers, floss, and snakeskin, which can plug downstream equipment.

Plastic processing can be defined as converting the plastics’ raw ingredients into (semi-) finished products.

These bulk plastics come in resin, granules, pellets, powders, sheets, preforms, or fluids and are converted into formed shapes or parts. Plastic materials can contain various additives that may influence their properties and processability.

After forming, the plastic part may be subjected to various processes such as welding, adhesive bonding, machining, and surface decorating.

There is a variety of methods used to process plastics raw materials. Each method has its advantages and disadvantages, and some processing methods are better suited for specific applications.

Before producing plastic products, specific plastic forming processes need to be determined.

The primary method used for processing plastic is injection molding. Injection molding is a manufacturing process for producing parts by injecting material into a mold.

Reaction injection molding (RIM) is a relatively new plastic process used in the industry. RIM is similar to injection molding, but RIM always uses lightweight, cost-efficient thermosetting polymers, unlike traditional injection molding.

Blow molding is used when the plastic item needs to be hollow. A molten tube is created with blow molding using compressed air, which blows up the line and forces it to conform to the chilled mold.

Plastic granules or pellets are fluidized, homogenized, and continuously formed in this process. The method of extrusion is usually used to make products such as tubing, pipe, sheet, film, coat wire, and cables.

With the compression molding process, the material is squeezed into its desired shape with the help of pressure and heat. Plastic molding powder and other materials are added to the mix to create unique qualities or strengthen the final product.

Transfer molding is generally used only for forming thermosetting plastics. Transfer molding is an adaptation of compression molding in that the molding powder or preform is charged to a separate pre-heating chamber and, when appropriately fluidized, injected into a closed mold.

Thermoforming is a manufacturing process where a plastic sheet is heated to a manageable forming temperature, formed to a specific part shape in a mold, and trimmed to create a usable product.

Several processes are used to convert the plastics’ raw bulk material into (semi-) finished products, and these processes are described above. Critical processes for handling bulk plastics include storage, big bag handling, conveying, pressing, rolling, extrusion, and molding.

Essential bulk plastic process equipment includes:

This plastics process equipment is used to process plastic products on an industrial scale.

Plastic recycling is the process of recovering waste plastic and reprocessing the (bulk) material into useful (semi-) finished products. The plastic recycling method has become more advanced and efficient in recent years. The plastic recycling process is an alternative to reduce waste and an economically viable option in the production of new goods. Plastics recycling involves collecting, sorting, washing, resizing, separating, extruding, pelletizing, and manufacturing processes.

The plastic processing market is a heavily-regulated and intensive industry, which makes staying up-to-date on all developments crucial, and helps plastic processors run their businesses more effectively. Receiving relevant insights regarding plastic processing innovations can be extremely useful to industry professionals responsible for operating, maintaining, and managing plastic manufacturing plants in the world. A plastic processing company is considered innovative when it invests significant capital in researching and developing a particular process.

Get the extensive coverage for dry material handling professionals who buy, maintain, manage or operate equipment, delivered to your inbox (it’s free!).

By signing up for our list, you agree to our Terms & Conditions.

Chatham

Chatham  Nashville-Davidson

Nashville-Davidson Olathe

Olathe Dresden

Dresden Grapevine

GrapevineGet the extensive coverage for dry material handling professionals who buy, maintain, manage or operate equipment, delivered to your inbox (it’s free!).

By signing up for our list, you agree to our Terms & Conditions. We deliver two E-Newsletters every week, the Weekly E-Update (delivered every Tuesday) with general updates from the industry, and one Market Focus / E-Product Newsletter (delivered every Thursday) that is focused on a particular market or technology.

Since 2010, we have been providing industrial professionals with the latest innovations, case studies, and the most comprehensive equipment guide in solids handling, in a variety of markets.

A

website

Chatham

Chatham  Nashville-Davidson

Nashville-Davidson Olathe

Olathe© BulkInside 2025

By signing up for our list, you agree to our Terms & Conditions. We deliver two E-Newsletters every week, the Weekly E-Update (delivered every Tuesday) with general updates from the industry, and one Market Focus / E-Product Newsletter (delivered every Thursday) that is focused on a particular market or technology..