Add to this the need to minimize cross-contamination of products or ingredients with allergens after production changeovers, and more processors are realizing that the traditional cumbersome means of cleaning conveying equipment may not be sufficient to meet today’s rigorous compliance requirements.

When conventional conveyors need to be disassembled, cleaned and reassembled to reach all exposed internal surfaces, potential downtime can extend to days. If this proves too onerous, some food processors dedicate separate conveyor lines to specific products, which increases capital equipment costs, labor, and the production space required.

As an alternative to speed the process, a substantial number of food processors have turned to tubular drag conveyor systems, which gently move product through a sealed, enclosed tube using a drag cable and circular discs pulled through on a loop — ideal for delicate items. Because tubular cable conveyors are enclosed, these systems can be quickly and effectively flooded with water, flushed, rinsed, cleansed, and thoroughly sanitized without disassembly – a process called “wet cleaning”.

This “wet clean” approach significantly improves food safety compliance and system reliability for a variety of food types such as nuts, frozen fruits and vegetables, grains, cereals, and powdered soups. The technique, in fact, thoroughly flushes out any potential allergens like nuts or gluten from conveying equipment. Typically, food processors must display a warning on packaging for consumers when the product is processed on equipment that handles nuts.

Since a complete and thorough cleaning can be accomplished without disassembly of the system, the entire process only takes 20-90 minutes. This can substantially reduce downtime during production changeovers and eliminate the need for unnecessary additional dedicated conveyor lines. For food processors conveying a specific product, regular cleaning can be set to run on an automated basis.

“We were proactively aiming to meet higher compliance standards while increasing the speed of packaging. Our previous pneumatic conveyor system was not up to the task. We found a solution in a tubular conveyor system capable of providing an extremely reliable conveyance, automated cleaning of the system without having to take it apart,” says Mark Koreis, Superintendent Processing/Packaging, at the Moses Lake, WA plant of National Frozen Foods Corp., a national processor of frozen vegetables since 1912 that processes more than 400 million pounds of product annually.

According to Koreis, the Moses Lake plant previously conveyed frozen peas, corn, lima beans, diced carrots, and legumes using a pneumatic conveyor to move products to bulk packaging areas. However, this was less than ideal for their application.

“Our previous pneumatic conveyor system generated a lot of heat, which is not good for frozen product, so we had to inject cool air into the system,” says Koreis. “Also, sanitation of the system presented challenges.”

According to Koreis, the cleaning process was inefficient and led to some downtime. As a result, the system was typically limited to conveying no more than 8 to 10 tons of product per hour.

“We sought a more reliable, precise, streamlined cleaning process, as well as increased production speeds,” says Koreis.

To resolve the issue, the plant replaced the pneumatic conveyor system with a tubular cable conveyor system with automated wet cleaning capability from Cablevey Conveyors. The Oskaloosa, Iowa-based conveyor manufacturer has designed, engineered, and serviced enclosed cable and disc tube conveyors for 50 years and is in more than 66 countries. In the food industry, conveyors are utilized for products such as nuts, cereal, snacks, beans, seeds, and coffee. The system can convey up to 2000 cubic feet per hour of materials with numerous layouts using multiple inlets and outlets.

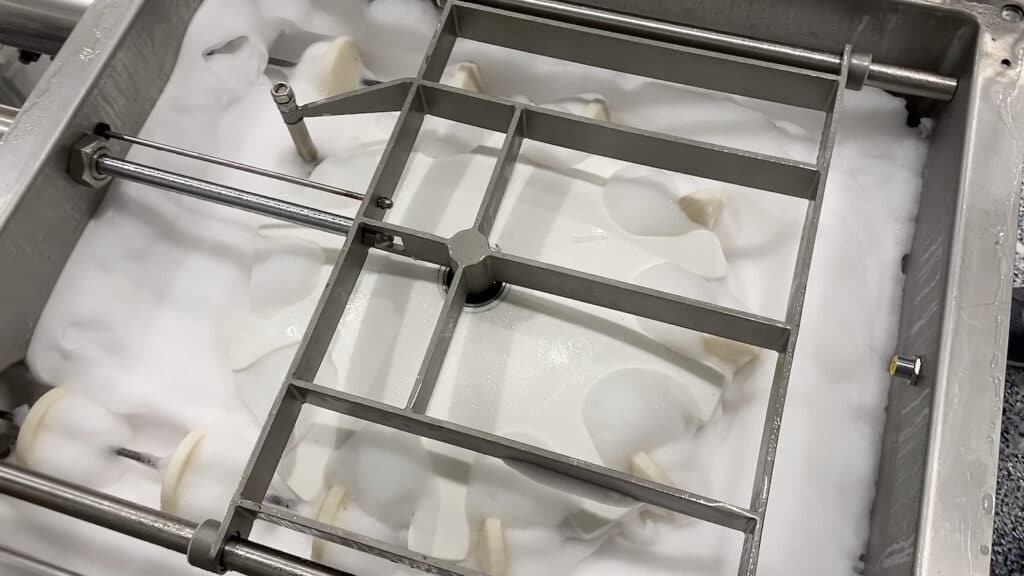

The cable conveyor’s wet cleaning process internally cleans the tube in several steps starting with a water rinse followed by a foaming agent, a sanitizing rinse, and a final water rinse. Once the system is thoroughly flushed out, drying is achieved by attaching urethane wipers to the tubular conveyor’s discs, which “act like a squeegee” to remove any residual water.

For the Moses Lake frozen food processing plant application, a six-inch diameter tubular conveyor system approximately a hundred feet long was installed to send products to be packaged in boxes or totes for shipping. To automate the cleaning process, Cablevey helped to integrate the conveyor with the plant’s distributed control system (DCS).

“By automating the cleaning, the Cablevey system is essentially self-cleaning,” says Koreis. “It is very convenient to let it run through the cleaning process and have employees take care of other tasks.”

According to Koreis, clear tubes were chosen as an option for the conveyor system to provide greater visibility into the cleanliness of the equipment and the cleaning process as it occurs. He also chose to add a unique inspection option that enables the running of a small, lighted camera system internally through the tubes, with video viewable on his smartphone via an app. Usually, this level of inspection is performed on an as-needed basis to further verify or document cleanliness.

“The tubular conveyor is clear except where the clamps are, so we can visually check at any time, and the internal camera system allows us to see every nook and cranny from the inside,” says Koreis. “This, along with regular ATP testing, gives us confidence that we are reliably meeting all necessary QA and food safety standards.”

“Compared to our previous air conveyor system, we are able to run significantly more – up to 15 tons an hour, with less downtime, and less breakage of delicate product,” he says.

Gaining Production Uptime and Flexibility

In the food processing industry, the wet cleaning capability is advantageous when dealing with a wide variety of products, including nuts, vegetables, grains, and flours, according to Steve Ives, Cablevey Conveyors Director of Business Development.

Ives notes that the wet cleaning process often has the greatest impact in operations that rely on open systems, such as bucket elevators or belt conveyors, which traditionally must be disassembled, cleaned, or soaked, and then reassembled – a labor and time intensive process.

In one example where the wet clean process was used, it dramatically streamlined cleaning, food handling and processing at a West Coast nut processor. The processor was using several bucket elevators to convey product in its nut conveyor system and had to spend several days a month on cleaning. To clean the equipment, the bucket elevators had to be shut down, powered off, protective shrouding removed, and then disassembled – with the process reversed to come back online.

When the processor switched to an automated wet cleaning system, however, it cut production downtime to a fraction of the time required and freed the work crew to take on other vital tasks, according to Ives.

In another example, a granola processor in the Northwest switched from belt conveyors to tubular cable conveyors that could be wet cleaned without disassembly. The goal was to streamline cleaning and flush out any potential nut allergens from the system.

“Instead of using basically dedicated lines, as was done previously, with the wet clean process they can run about five or six different products through the same line while remaining compliant. That has significantly improved their efficiency and production flexibility,” concludes Ives.