To make sure weight measurements are correct, it is important to utilize equipment such as load cells and instrumentation.

An essential part of capturing weight data is the load cell. Load cells are what measure the force of the load being applied to the scale. Without a load cell, a scale wouldn’t be able to measure weight.

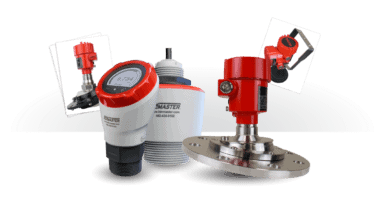

There are multiple types of load cells, constructed out of aluminum, tool steel or stainless steel. The most appropriate load cell for a particular process depends on the loading conditions and the surrounding work environment. Whether single point, S-beam or canister-style, Rice Lake has a load cell for any washdown, tank, and hopper or suspended weighing application.

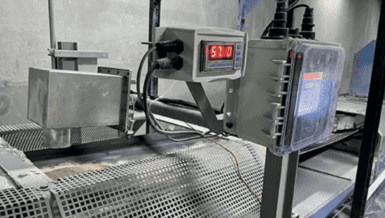

After load cells measure an object’s force, instrumentation such as a digital weight indicator is used to communicate the weight of an item on a scale through a display. The recorded weight data can then be integrated into a process where such measurement is necessary.

A more advanced weight indicator can control nuanced processes involving more than one data point and may offer remote capabilities. This feature gives an operator access to weight data without requiring them to be physically present at a workstation, simplifying processes.

Rice Lake Weighing Systems offers a complete selection of digital weight indicators and load cells designed to enhance process control.