Background

Their materials are extremely abrasive, so the solution required needed to address this. As 3Sigma was a logical choice as we manufacture both the required bulk bag unloader and the GeoMate™ mass flow feeder which operates with no moving parts.

Customer Needs

- Provide a system that will discharge this very difficult product without issues.

- Dust-tight design – contain all spills.

- Feed and batch less than 25 lbs. with +/- 0.10 lb. accuracy.

- Heavy-duty design to ensure uptime and minimize maintenance.

- Integration of all equipment needed.

Solution

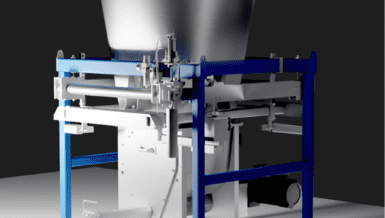

- Provided our Massage-It™ bag massaging system, which consists of a heavy-duty pipe weldment, to properly massage and discharge this product. There is no chance of bending this robust design. In addition, the paddles rotate a full 90-degrees, forcing the product into the critical flow path of the bulk bag.

- Contain-It™ chamber with Tube-It™ discharge tube for total containment.

- The Close-It™ Valve was provided to allow for bag changeouts.

- The two opposing elliptical plates, which are encapsulated within each other, concentrically close for optimal product shutoff.

- GeoMate™ mass flow feeder to meet batch time and accuracy.

Our oversized Contain-It™ Chamber contains all product spills. The heavy-duty design is built for years of trouble-free operation.

Our automated dust valve was provided to connect to the dust collection system. This is located on the side of the access chamber. When the door is opened the valve opens, when the door is closed the valve closing, allowing for dust collection to be used only when needed, minimizing the total CFM required.

The Tube-It™ provides a seal with the bulk bag outlet spout as shown above. The discharge spout goes down into the Tube-It™ 4-8”. As the dust-tight seal is made within the access chamber WHEN material spills occur THEY ARE CONTAINED.

The GeoMate™ mass flow feeder was fitted at the outlet of the Contain-It™ chamber. A level control outputs ‘bag empty’. The GIW feeder operates in a fast/dribble mode of operation to properly batch the various silicates to a container on a scale. As the feeder operates with no moving parts, it was an ideal selection for the GeoMate™ vibratory feeder.