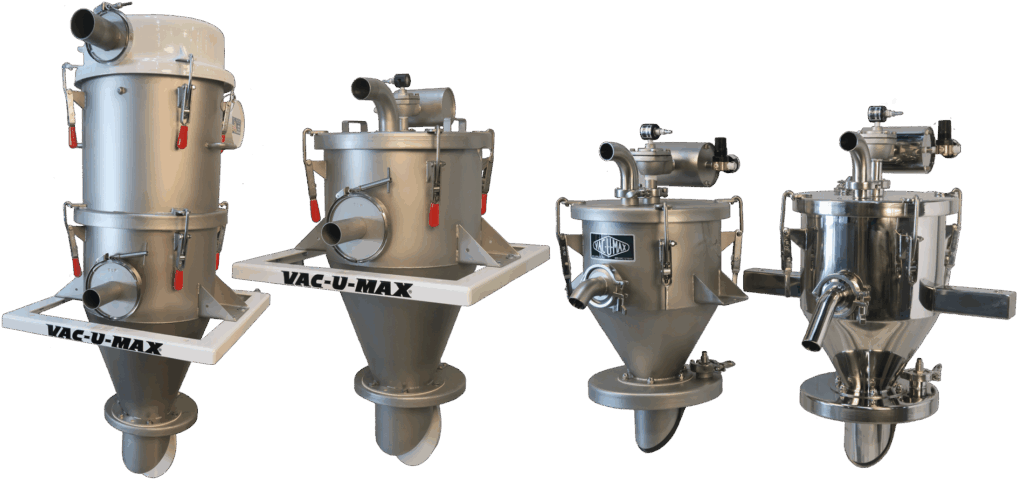

VAC-U-MAX is a worldwide leader in bulk material handling, specializing in the design and manufacture of pneumatic, aero-mechanical, and flexible screw conveying systems and support equipment for conveying, weighing, and batching over 10,000 different powders and bulk materials.

Serving industries such as food, pharmaceutical, nutraceutical, nonwovens, chemical, petrochemical, plastics, and more, VAC-U-MAX provides innovative and reliable solutions tailored to the specific needs of each industry.

Our systems are engineered to deliver precision and efficiency, ensuring seamless integration into a wide range of manufacturing processes.

Product range also includes explosion-proof industrial vacuum cleaners, continuous duty vacuum cleaners for high volume recovery, and custom central vacuum cleaning systems.