The Clean-In-Place feeder also features a novel sealing design that replaces stuffing boxes on the drive shafts with proprietary lip seals at the feeding tool and intromitter. Connections remain tight during both operation and cleaning to prevent leakage, even in critical interfaces with moving parts.

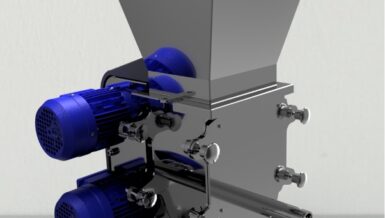

The CIP feeder expands the Feedos S line of feeders, which also includes standard, hygienic, and pharmaceutical models to suit virtually any process feeding application. The feeders meter and dose a wide range of flow-resistant and free-flowing powders, granules, flakes, and other dry, bulk materials, automatically and with high accuracy. Testing is offered in the company’s New Jersey test laboratory.