In this blog, we discuss what a rotary airlock is and how it works, as well as the major benefits using one brings to your bulk material handling system.

What is a rotary airlock?

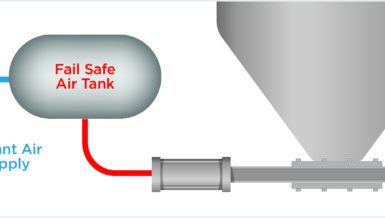

A rotary airlock transfers dry, free-flowing bulk solid materials from a bin, silo, receiver, hopper, or cyclone into the conveying line at a controlled rate.

While not completely airtight, they’re precision-built to limit air leakage and pressure loss between the inlet and outlet ports. This prevents the system’s gas or high-pressure fans from interfering with the movement of materials through the conveying line. As well as ensuring a consistent flow of materials, rotary airlocks are useful as pollution-control devices to protect against product contamination.

Rotary airlocks are commonly used to convey:

- Abrasive materials

- Chemicals

- Food

- Grain

- Paints

- Paper

- Pharmaceuticals

- Plastics

- Rubber

- Textiles

- Tobacco

- Wood

How do rotary airlocks work?

A standard rotary airlock consists of six, eight, or 10 metal vanes evenly spaced around a rotary shaft. When the airlock is turned on, a motor causes the vanes to rotate inside the housing, much like a revolving door. This allows materials to be metered into the system at a controlled rate.

The space between the metal vanes is called a rotor pocket. Dry bulk materials flow into the rotor pocket from a dispenser above and flow out through the bottom into the conveying line as the rotary airlock turns.

3 major benefits of using a rotary airlock

1) Seals materials handling systems against pressure loss

The tight clearance between the vanes and the housing in a rotary airlock helps maintain the pressure differential between the dispenser and the conveying line. This is particularly important because the pressure between each bin, silo, or hopper tends to be different. It’s also why rotary airlocks are placed either at the beginning of a pressure system or at the end of a vacuum system.

Without a rotary airlock, it would be difficult to maintain suitable pressures within each part of the dry bulk materials handling system. This would prevent materials from flowing smoothly and cause the lines to become blocked, leading to increased downtime and maintenance costs.

The more vanes a rotary airlock has, the greater its ability to limit pressure loss. However, this also means the size of each rotor pocket will be smaller, and less material can be deposited from each. This should be taken into account when designing a materials handling system that features a rotary airlock.

2) Feeds equipment for value-adding processes

Dry bulk material handling facilities use mechanical process equipment to add value. For example, mineral companies might want to classify and screen materials to create multiple grades, while pharmaceutical companies may want to blend active and inactive ingredients.

But if the materials are allowed to flow freely, the pipes and components would become flooded and blocked. So in order to function properly, this value-adding equipment needs a controlled feed of materials.

There are alternative methods for controlling material feed streams. But for systems that rely on gravity flow, a rotary airlock provides an effective and simple solution that streamlines material conveying at a minimal cost.

3) Unloads fines from dust collection systems

To function properly, dust bag houses use a vacuum to pull fine particles from the upstream process. As the filter cartridges become filled with dust, timed pulses of high-pressure air blow down their lengths. This knocks the dust off the filter, freeing up space for more dust collection.

As this happens, heavier fines collect at the bottom of the central dust housing. They can be removed by shutting down the dust collection system, opening the hopper, and unloading the fines manually. But this limits productivity and takes time away from other valuable tasks.

Another solution is to use a rotary airlock to maintain the vacuum seal and remove the fines without shutting down the system. That way, the system can continue running and operators can focus on their other duties without distraction. Maintaining the vacuum using a rotary valve also allows manufacturers to reclaim fines for high-value items and recycle them back into the upstream process.

Optimize your production with maintenance-free, tight-tolerance rotary airlocks

Installing a rotary airlock enables manufacturers to precisely control material flow through their dry bulk materials handling system. This prevents flooding and pressure loss while also protecting against product contamination. To achieve the greatest benefits of using a rotary airlock, it’s important to get your components from a trusted and experienced supplier like Progressive Products Inc.

Our industry-leading rotary airlocks require no field adjustments and remain maintenance free for the life of the seal, making them easy to install and use. At 8”, our smallest valve has .004”-.005” end clearances and .003”-.005” diameter clearances, giving your system a supreme pressure seal. And while these components typically come with a compression-type design, we also offer T-seals for exceptional performance in severe operating conditions.

Take a look at our rotary airlocks product page to get specifications and request a quote, and bring your system one step closer to its full operating potential.