REQUIREMENT

Make a weighing and batching system, installed in a dedicated machine for the production of mixtures with a continuous cycle in the ceramics sector.

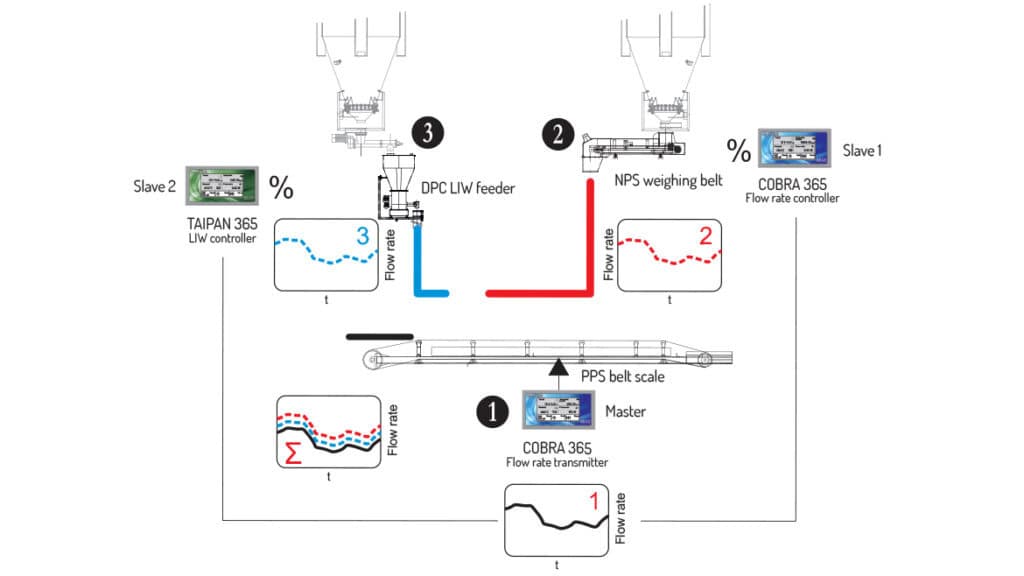

The system is used to monitor the continuous feeding of clay and adjust the batching of the additives required for ceramics production, with a constant proportion in relation to the variable flow of clay.

OUR SOLUTION

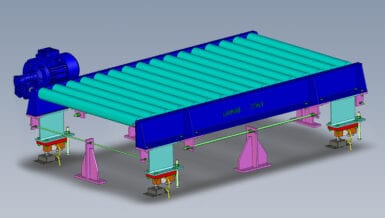

- 1 weighbridge for conveyor belt;

- 1 weighing belt with a batching unit;

- 1 weight-loss batching unit;

- 2 AZS 100 kg single-point load cells;

- 2 AZL 10 kg single-point load cells;

- 1 PEC 150 kg single-point load cells;

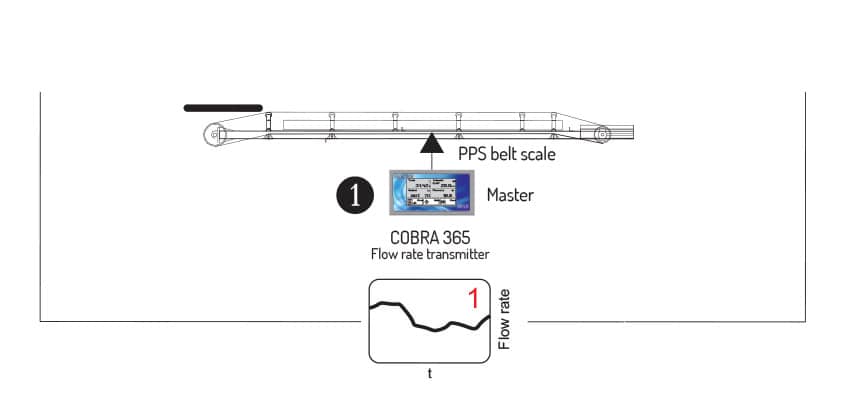

- 1 COBRA 365 weight indicator, with a flow transmitter function;

- 1 COBRA 365 and 1 TAIPAN 365 weight indicators, with a flow regulator function.

HOW DOES IT WORK?

The weighbridge, under which are positioned the 2 AZS load cells, measures the instantaneous flow rate of the clay transported on the belt.

The weighbridge is connected to a COBRA 365 flow transmitter, which calculates the instantaneous flow rate of the clay and perform the role of “master” controller, transmitting the data to the subsequent “slave” controllers.

While running, the clay passes under the weighing belt that acts as a slave percentage batching unit and releases the first additive.