As Biovation grows and pursues manufacturing excellence for nutraceutical products, processing equipment such as mixers and sifters are key parts of the equation. Patrick Browne, Director of Operations at Biovation Labs, found reliable processing solutions with Kason Corporation and Marion Process Solutions for improving efficiency and quality in nutraceuticals.

Superior Sifting with Kason

When expanding production capabilities at Biovation, Browne recognized a need for a sifter larger than the 24-inch sifter that the company had been using. He was connected with Kason through Annik Engineering, Kason’s local engineering and integration representative in the Utah area. Biovation purchased a 60-inch Kason double-deck VIBROSCREEN circular vibratory screener with custom modifications on the base.

When looking to expand production again and make screening and sifting easier, Browne turned back to Kason for a 30-inch bag dump screener station, model KBDS-30-SS. Biovation realized a significant reduction in loading time with the bag dump station. Because of that improvement in their process, Browne ordered two more identical units so that each line with a mixer now also has a Kason bag dump screener.

“I was looking for something that could make screening and sifting a little easier than the current multistep process I was using: transfer batches straight through a screener discharge to a drum or barrel, then load it into a mixer. I reached out to Annik and they informed me that Kason had bag dump stations built into screeners,” Browne recounted. “I purchased the first one and it worked great. It actually helped reduce our loading time. I ordered two more, I have been quite happy with them. It also fit perfectly with the unique layout of our facility.”

The reduced height for the bag dump station meant that Browne could place them under the mezzanine in the building without any issues.

Better Mixes with Marion

When Biovation needed to replace an old mixer, Browne turned to Kason’s sister company Marion Process Solutions, a mixing and blending equipment producer he had become familiar with before joining Biovation.

“I did a lot of research and liked everything I had read about Marion products and the people I spoke with about it, so I kept in contact. And we now have a 60-cubic-foot Marion mixer,” said Browne. “One of the things I wanted to do was reduce the blend time that we had prior to the Marion. I was also looking to produce a better blend.”

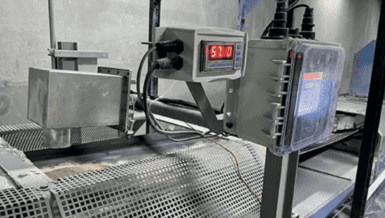

Improving the mix for Biovation’s products included shortening mixing time, maintaining material integrity, and producing a better homogenous mix without breaking down the products. By switching to the Marion mixer, Biovation was able to shorten mixing time from 15-18 minutes per batch to approximately 3 minutes. This reduction in mix time helps the company improve throughput, even when switching to a smaller capacity mixer. The 60-cubic-foot Marion mixer that Biovation operates replaced a 75-cubic-foot model from another manufacturer. However, Browne is able to run the same size batches on the Marion.

“We’re getting a better mix in a fraction of the time,” Browne added. “Marion is very approachable and easy to work with. They are more personable than other companies. We have another mixer that will need to be replaced soon and will be adding another Marion to the mix.”

Processing Equipment Partners

When selecting any processing equipment, Browne looks for a supplier that can provide excellent customer service and support, cost-competitive solutions, and reliability that he can trust to keep Biovation’s production on schedule.

Both Marion and Kason provided quality processing equipment that Biovation will continue to work with in the future. Both companies have become partners for Browne, who has appreciated the excellent service and responsiveness.

“When we first started the projects, their teams were engaged even without knowing whether we’d end up making a purchase from them,” Browne noted. “They spent ample time with my team to make sure that they were trained and comfortable with breakdown and cleaning processes.”

Browne also spoke to the craftsmanship for Marion and Kason products, stating that “both manufacturers’ equipment are very robust and well-crafted.”