As a full service manufacturer, 4B goes beyond selling. 4B’s Tech Team offers a comprehensive training program to their customers or their preferred electrical contractors on best installation practices and maintenance.

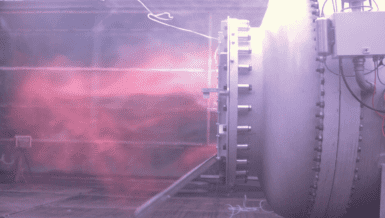

The 4B partnership helps change safety culture by proactively focusing on what matters most.

As part of the service, experienced 4B technicians assess material handling equipment in the plant to help their customers discover what critical safety devices may be needed to protect the equipment and personnel from the dangers associated with explosive dust.

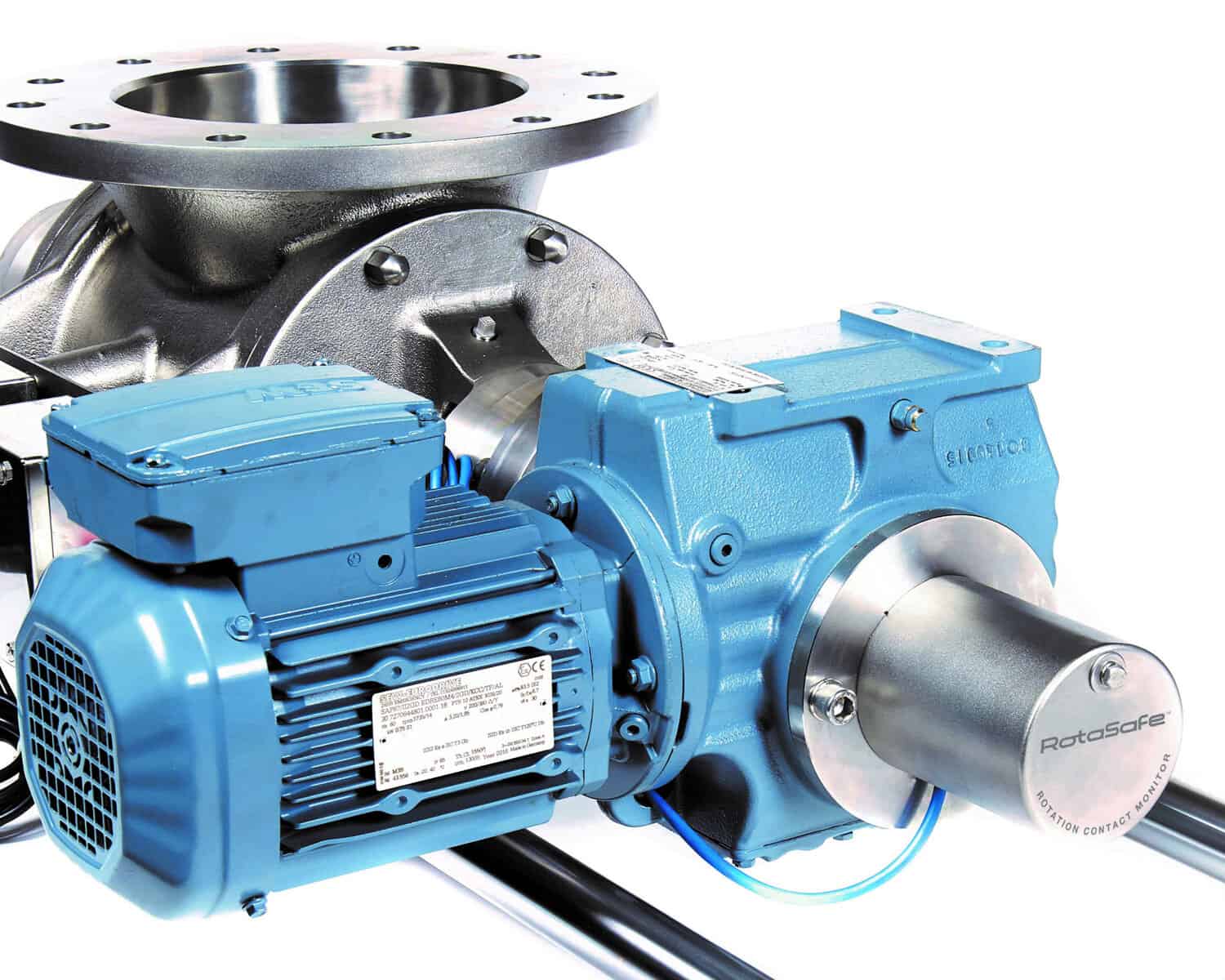

- Bearing Temperature Sensor

- Zero Speed Sensor

- Belt Misalignment Sensor

- Plug Switch

- Conveyor Belt Alignment and Rip Sensor

- Open Conveyor Pull Cord Safety Stop Switch

4B technicians document their discoveries into a formal report and work with their customers’ safety personnel to:

- Update Safety Programs

- Develop Maintenance Schedules

- Educate Staff

- Train Preferred Electrical Contractors

Contact 4B for more information.

ABOUT 4B GROUP:

Founded in 1971 as a subsidiary of The Braime Group, 4B GROUP has been an industry leader in developing high quality, innovative, and dependable material handling components for the agricultural and industrial sectors.

4B’s product line ranges from elevator buckets, elevator bolts and drop forged conveyor chain to level monitors, speed switches and hazard monitoring systems. With offices in North America, Europe, Asia, Africa and Australia along with a worldwide network of distributors, 4B can provide practical solutions for applications in any location.