Particularly in the area of explosion protection, as well as pressure venting at medium to very high overpressures, the existing concepts must be carefully reviewed using the available models, and possibly re-evaluated. A comparison of the explosion characteristics of stoichiometric methane-air and hydrogen-air mixtures quickly makes this necessity clear.

Fig. 1: Comparison of explosion characteristics under atmospheric conditions (20°C; 1.01 bar)

Sources: BAM final report on research project 2539 and own investigations.

If the maximum explosion pressure at atmospheric conditions is about 8 bar in each case, significant increases can be observed both in the KG value (rate of pressure rise) and in the laminar flame propagation speed. This may mean that safety devices tested with methane explosions show too high inertia for the rapid pressure increase. Valve-type protective systems can be severely damaged when they respond that they do not return cleanly to their original state and their functionality is impaired or they are operated unsafely. Special care must be taken when designing and assessing the geometric dimensions and sizing. For example, certain length-to-diameter ratios of vessels and pipes, especially for hydrogen as a Class IIC gas, favour the tendency towards detonative transition. If explosions propagate from one vessel to another via a pipe, there is also the risk that the ignitable mixture is pre-compressed in the second vessel, which results in significantly higher explosion pressures compared to explosions under atmospheric conditions. A hydrogen-air mixture is also more susceptible to ignition than a methane-air mixture due to the lower ignition energies and ignition temperature. In addition to the expected more severe course of events, the probability of occurrence is also higher.

Hydrogen explosions under prepressure

In addition to the aforementioned secondary pressurisation in the event of an incident, there are applications in which ignitable mixtures are deliberately precompressed and can ignite uncontrollably under certain circumstances. For several reasons, these scenarios pose a special challenge with regard to the design of the corresponding equipment and to the constructive protection concepts.

Firstly, the existing normative regulations do not provide any models for the design of safety relief devices for gas explosions under prepressure. Due to the prepressure at high dynamics, the problem at hand is neither covered by DIN EN 14994 (Gas explosion venting protective systems) nor by DIN EN ISO 4126 (Safety devices for protection against excessive pressure). Thus, there are no assured design standards, which means that the problem is in the “grey area of safety technology”. Secondly, the explosion dynamics are significantly influenced by barely assessable turbulence-generating effects, which primarily result from the geometry at hand. Thus, it is difficult to predict what explosion pressures, flame propagation speeds and rates of pressure rise are to be expected. Whether a detonative transition occurs and whether an explosion venting device is suitable to protect the present scenario therefore requires separate investigations.

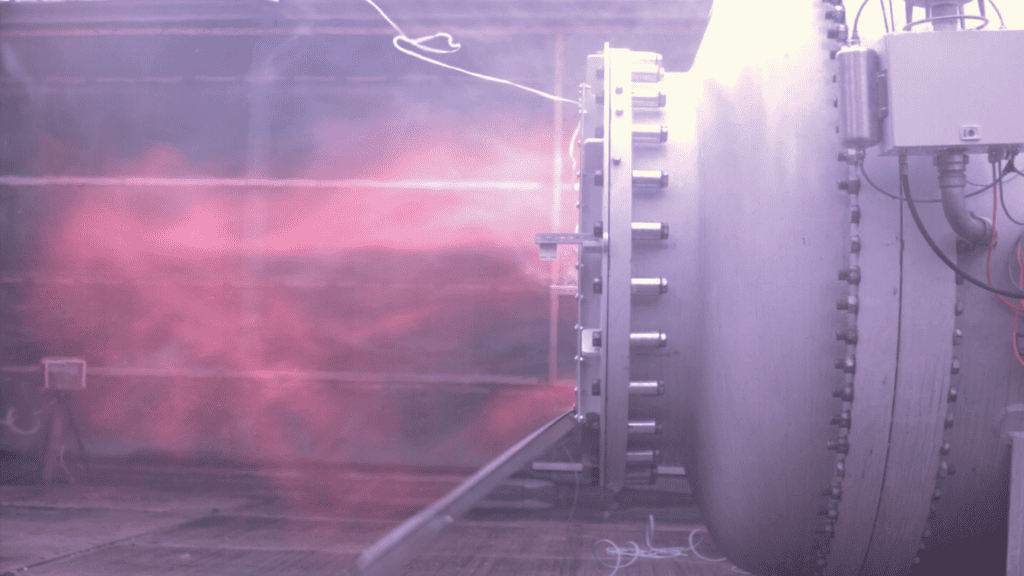

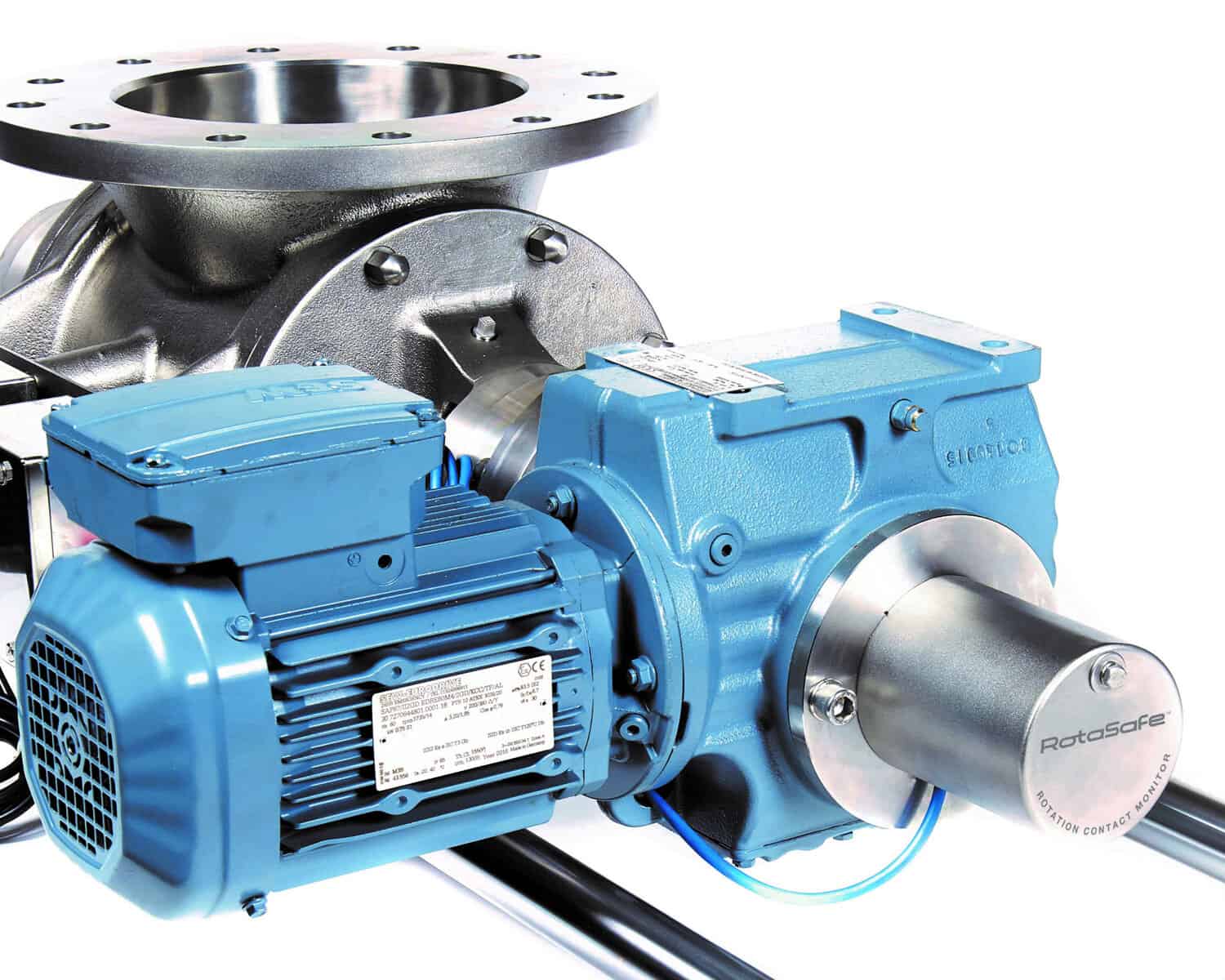

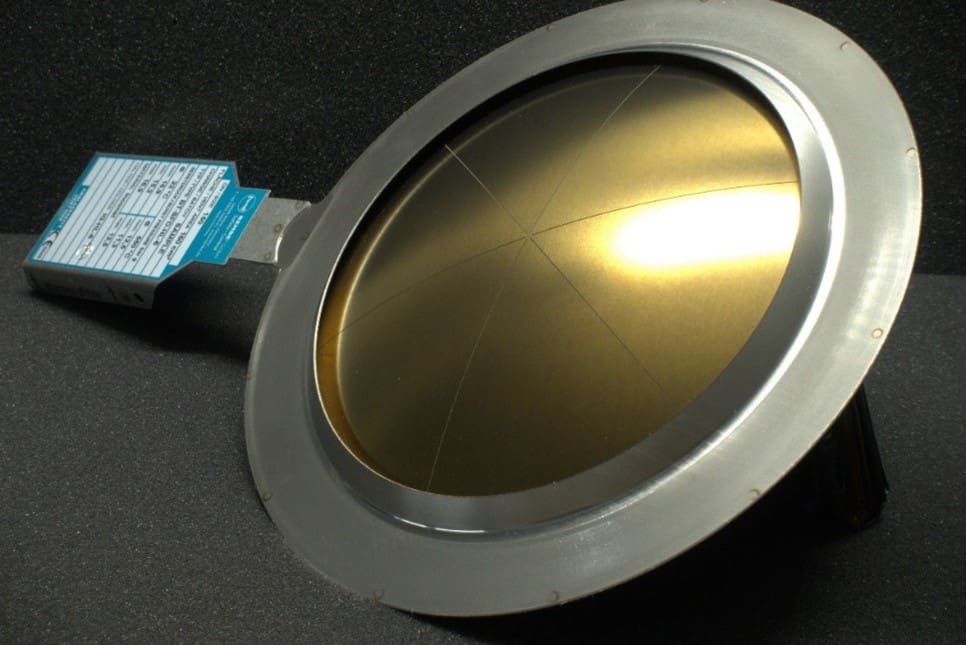

One possible way to validate a safety concept for the “hydrogen explosion under prepressure” problem dealt with here – in addition to very complex numerical simulations – is experimental verification. For this purpose, the protection scenario is simulated as realistically as possible with flameproof components and the explosion pressure resistant concept is tested with regard to its functionality via repeated explosion tests. Starting from a stoichiometric methane-air reference test, either the proportion of hydrogen in the methane-hydrogen-air mixture, the prepressure or the combustion air ratio is increased when testing a pure hydrogen-air mixture, depending on the problem. By registering the pressure curves within the simulated structure, the maximum explosion pressure can be inferred and the tendency towards detonative transition can be estimated. The aim of the verification is always the identification of safe operating parameters as well as to check product suitability, as no standard product certification is available due to the lack of a normative basis. When selecting a suitable product/explosion venting device, it is important to ensure that it is not only suitable for explosion venting, but also guarantees a long and reliable service life under the prevailing conditions during normal operations. If the explosion venting device was an explosion vent or rupture disc, the burst pressure, operating ratio, working temperature as well as the occurrence of vibrations and cyclic loads and, of course, the corresponding material must be taken into account when making the selection.

REMBE GmbH Safety+Control has been a leader in the technological fields of Process Safety and Explosion Safety for almost 50 years. As such, the careful selection of suitable safety systems and (explosion) relief devices is a key aspect of the company’s service portfolio. REMBE has thus built up a profound understanding of how to analyze customers’ processes and plants and identify suitable protection technologies. In collaboration with REMBE Research+Technology Center GmbH, an independent testing laboratory accredited to EN ISO / IEC 17025:2018, REMBE can also validate even highly complex protection concepts on an experimental basis. Especially in scenarios where new technologies need to be tested, no assured design standards are available or high-precision protection concepts are required, it is precisely this multidisciplinary approach that enables REMBE to develop high-quality solution concepts. In collaboration with the customer, the company combines experimental verification with its extensive expertise in explosion safety and explosion venting solutions to create highly specific protection concepts tailored to the customer’s processes.