What Is an Explosive Atmosphere?

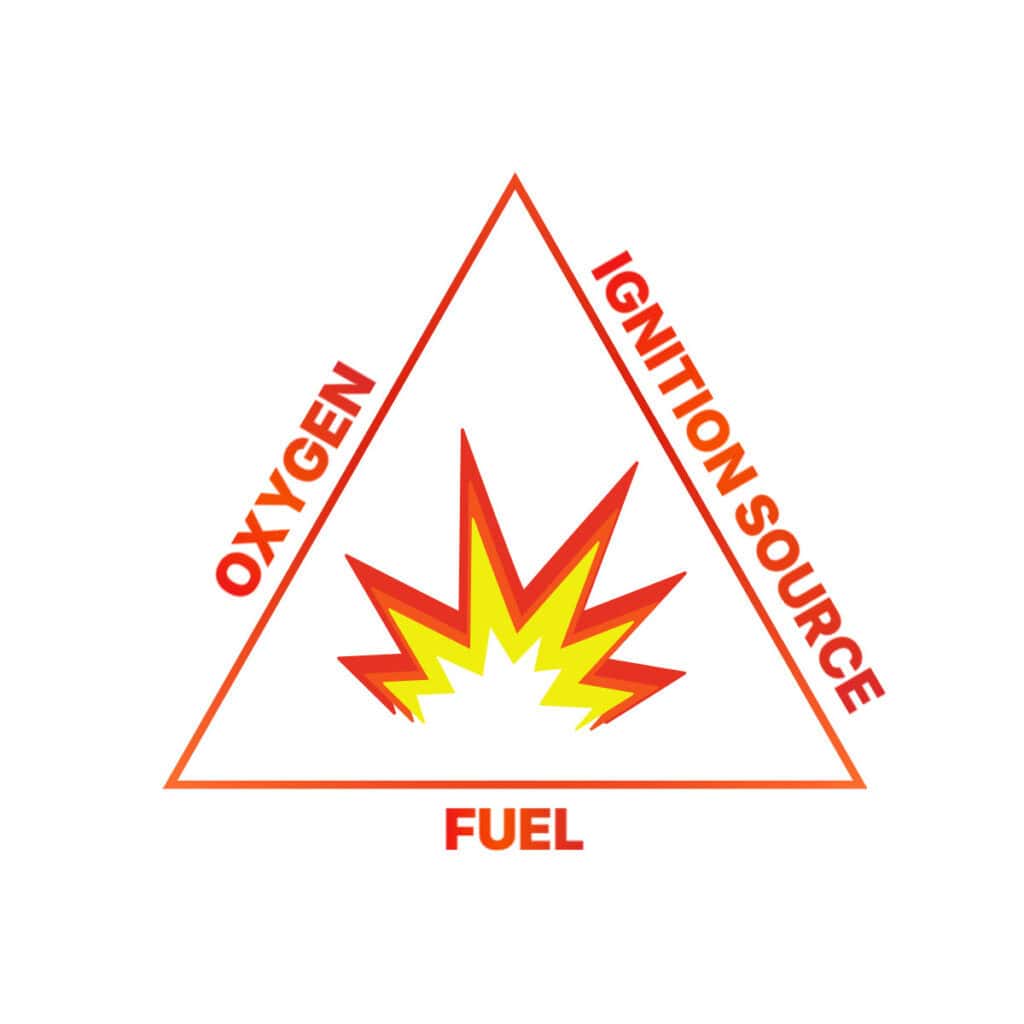

An atmosphere is considered explosive when it simultaneously contains:

- Fuel (cloud of dust, gas, or both)

- Oxygen (typically air)

In such conditions, a potential ignition source—such as a spark, flame, or heat—can lead to an explosion.

The Objective of designing ATEX-Compliant equipment

The goal of designing ATEX-compliant equipment is to eliminate all possible ignition sources that could trigger an explosion. An important factor that also needs to be taken into consideration when is how often the explosive atmosphere may be present during a year.

The ATEX Directive: 2014/34/EU

Within the European Union, the document pertaining to the construction of equipment suitable for the installation in explosive atmospheres is the Directive 2014/34 EU, concerning the harmonization of the laws of the Member States relating to equipment and protective systems intended for use in potentially explosive atmospheres, also known as the ATEX directive (acronym of the words ATmosphères Explosives).

Certifying ATEX equipment thus means meeting all the requirements of Directive 2014/34 EU.

Understanding Hazard Zones

The first step we take is to determine the duration of the explosive atmosphere: the higher the percentage, the higher the risk (probability) of explosion.

Zones are used to categorize the frequency and duration of explosive atmospheres:

- Gas: Zone 0 (continuous), Zone 1 (frequent), Zone 2 (occasional)

- Dust: Zone 20 (continuous), Zone 21 (frequent), Zone 22 (occasional)

Zone 0 represents the highest level of risk for gas-related explosions whereas, Zone 20 represents the highest level of risk for dust-related explosions.

Steps to ATEX Certification at COMAV

Once we’ve assimilated the above-mentioned information, the activities to be implemented for the ATEX certification of standard equipment for internal zone 20 are essentially the following:

- Preparation of a Technical Dossier – The dossier includes the analytical definition of all the possible sources of ignition and the activities to be put in place so that these do not become effective (i.e. that the possibility of ignition is not achieved). To do this, we use specific technical standards defined as conformity.

- Third-Party Verification – The technical dossier and product samples are submitted to an authorized third-party. If all criteria are met, an EU-type examination certificate is issued.

- Implementation of a Certified Quality System – A quality system compliant with ISO/IEC 80079-34, to ensure production consistency, must be implemented. This system is also subject to ongoing third-party monitoring.

Once all these steps are completed, the product can be placed on the market with ATEX markings on the nameplate, accompanied by a Declaration of Conformity.

Our Trusted Certification Partners

COMAV collaborates with highly respected certification parties such as TÜV Nord and Dekra. You can view our equipment certificates and quality system surveillance documents on our website.

Examples of nameplates with ATEX marking

Below are some images referring to the analysis carried out in COMAV

Conclusion

In conclusion, the ATEX certification is a critical safeguard when designing and manufacturing equipment intended for use in potentially explosive atmospheres. At COMAV, our commitment to safety, compliance, and technical excellence is reflected in our meticulous approach to certifying our equipment. By adhering to the rigorous standards of Directive 2014/34/EU and collaborating with renowned certification bodies like TÜV Nord and Dekra, we ensure that every product we bring to market meets the highest standards of safety and reliability.