SILOTOP® ZERO is not just an evolution of its highly appreciated predecessor but the result of some 50 years of expertise in dust filtration technology. With its new NANO-FIBRE filter media, SILOTOP® ZERO makes silo venting in concrete plants even more eco-friendly reducing dust emission to less than 1mg/Nm3.

Thanks to the new filter technology, SILOTOP® ZERO provides top performance features on a much smaller filter surface area than SILOTOP® R03. SILOTOP® ZERO offers user benefits that conventional silo venting filters do not even come close to.

The collector is equipped with ISO group ePM2.5 POLYPLEAT™ filter elements made by WAM®. SILOTOP® ZERO can handle peak flow rates of 1,500 Nm3 /h with filter surface of 14.0 m2 and 2,600 Nm3 /h with 24.5 m2 at low can velocity ensuring up to 20% shorter silo filling time than conventional dust collectors; in other words, the complete unloading of a tanker takes less than 30 minutes. The special design of the highly efficient air jet cleaning system, which is integrated into the hinged weather protection cover, ensures low air consumption of only 1.8 Nm3 /h resulting in 50% lower operating costs than conventional filters.

Thanks to the unique interception capability of the nano-fibre, both filter media and cleaning system design ensure ideal air filtration capacity throughout the working cycle. The lifetime of SILOTOP® ZERO filter elements is more than double in comparison with conventional filters. SILOTOP® ZERO has a robust design, which satisfies the market needs guaranteeing high resistance of up to 750mmH2O (0.075 bar / 7.5 kPa) positive pressure and 500mmH2O (-0.05 bar / 6 kPa) negative pressure.

Its total weight of only 68 kg facilitates installation, while its body rim height of barely one metre makes filter element replacement particularly comfortable.

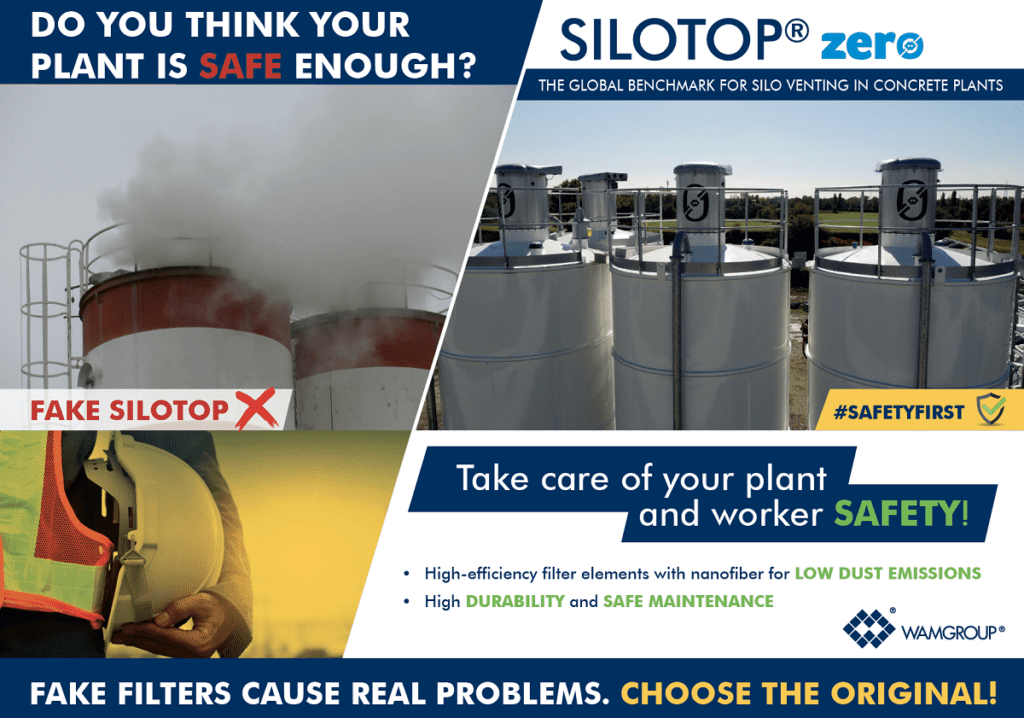

Interchangeable with its predecessor, SILOTOP® R03, SILOTOP® ZERO, is an industrially manufactured dust collector with a stainless-steel housing. All components are manufactured in house on state-of-the-art production machines. Mass-produced in advanced automated processes, SILOTOP® ZERO offers customers not only top quality but also an exceptional price-performance ratio.

Moreover, WAMGROUP®’s global subsidiary network ensures ex-stock availability of both complete SILOTOP® ZERO filters and spare parts. Our subsidiaries’ skilled staff will help you identify the correct part and they will advise you on where to source original spare parts and service at a fair price. To ensure smooth operation and longevity of our products, we recommend you beware of copycats. Choose original SILOTOP® ZERO filters and original spare parts only. In this way you will protect your plant and benefit from a constant performance balance over time.